913218/CP0307 44 PRINTED IN U.S.A.

GREASING

Refer to the illustrations and listings for fitting loca-

tions. Wipe dirt from the fittings before greasing them

to prevent contamination. Replace any missing or dam-

aged fittings. To minimize dirt build-up, avoid exces-

sive greasing.

BASIC MACHINE

GREASE FITTING LOCATIONS

Every 50 Hours (or weekly)

Refer to the illustration on the facing page for loca-

tions.

--- BOOM AREA ---

1. Boom to frame upright pivot pins (2)

2. Rod end slave cylinder pivot pins (2)

3. Rod end lift cylinder pins (2)

4. Extend cylinder pin

5. Chain sheaves pins, (2)

6. Dynattach to boom nose pivot pins

7. Tilt cylinder pivot pins (2)

8. Boom slide pads - as required, front and rear

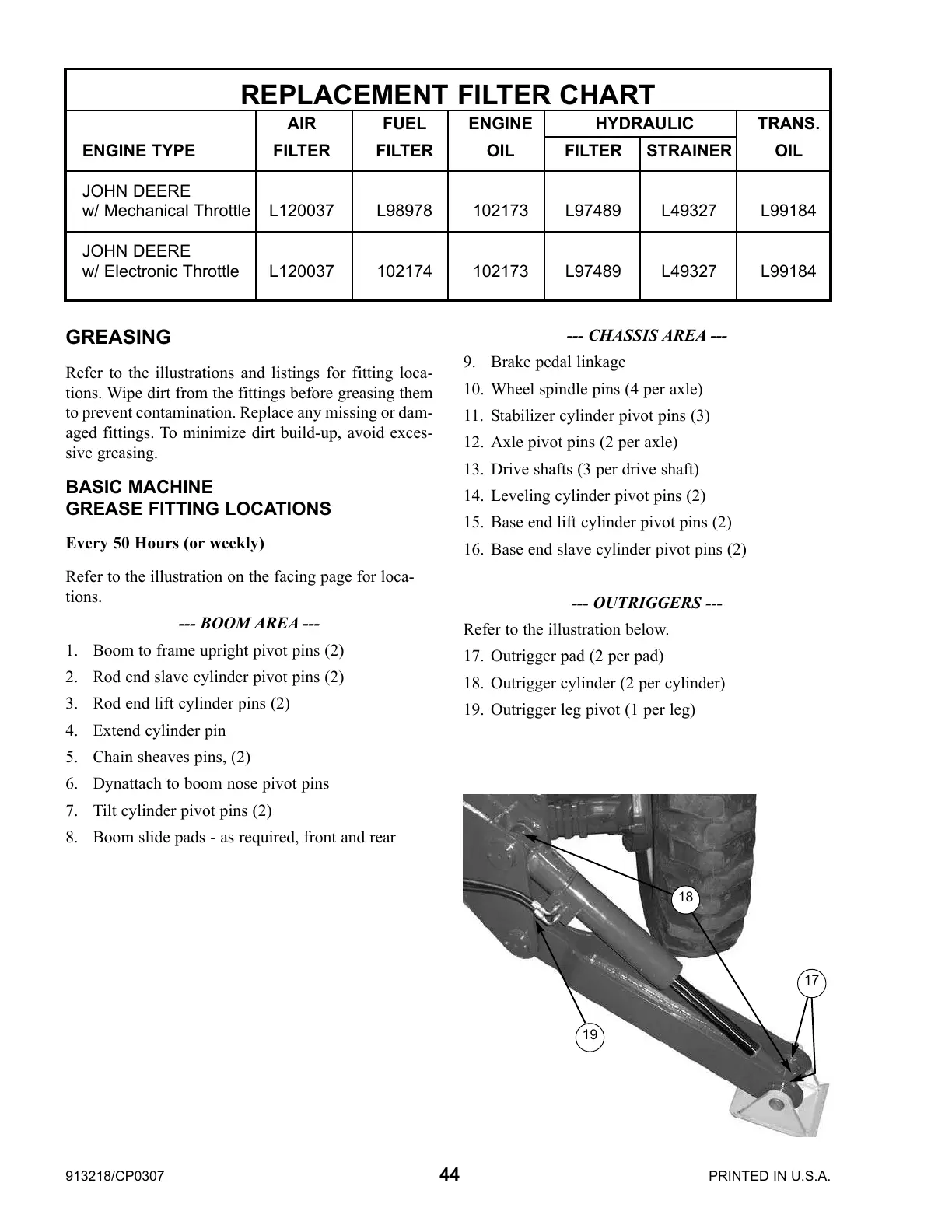

REPLACEMENT FILTER CHART

AIR FUEL ENGINE HYDRAULIC TRANS.

ENGINE TYPE FILTER FILTER OIL FILTER STRAINER OIL

JOHN DEERE

w/ Mechanical Throttle L120037 L98978 102173 L97489 L49327 L99184

JOHN DEERE

w/ Electronic Throttle L120037 102174 102173 L97489 L49327 L99184

--- CHASSIS AREA ---

9. Brake pedal linkage

10. Wheel spindle pins (4 per axle)

11. Stabilizer cylinder pivot pins (3)

12. Axle pivot pins (2 per axle)

13. Drive shafts (3 per drive shaft)

14. Leveling cylinder pivot pins (2)

15. Base end lift cylinder pivot pins (2)

16. Base end slave cylinder pivot pins (2)

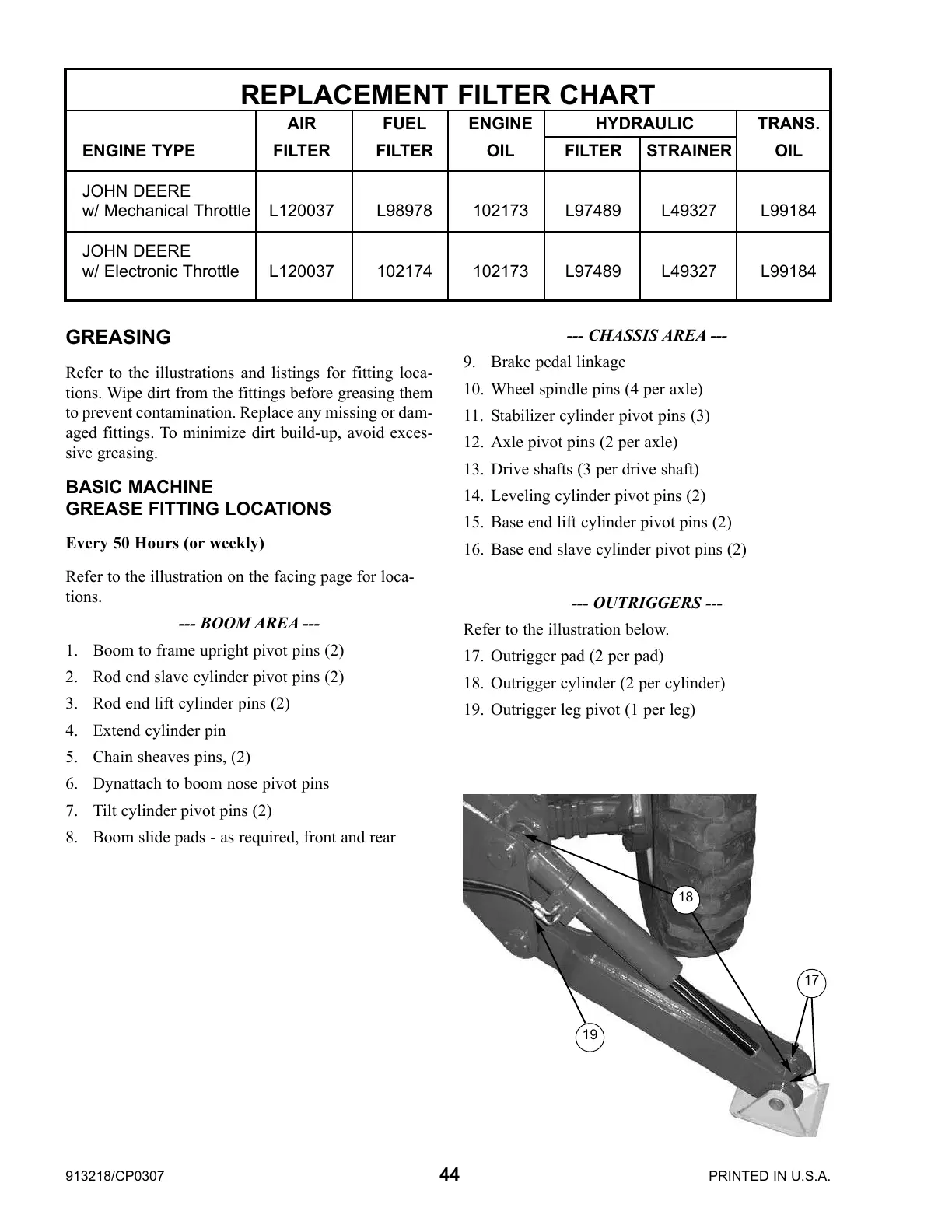

--- OUTRIGGERS ---

Refer to the illustration below.

17. Outrigger pad (2 per pad)

18. Outrigger cylinder (2 per cylinder)

19. Outrigger leg pivot (1 per leg)

17

19

18

Loading...

Loading...