913218/CP0307 58 PRINTED IN U.S.A.

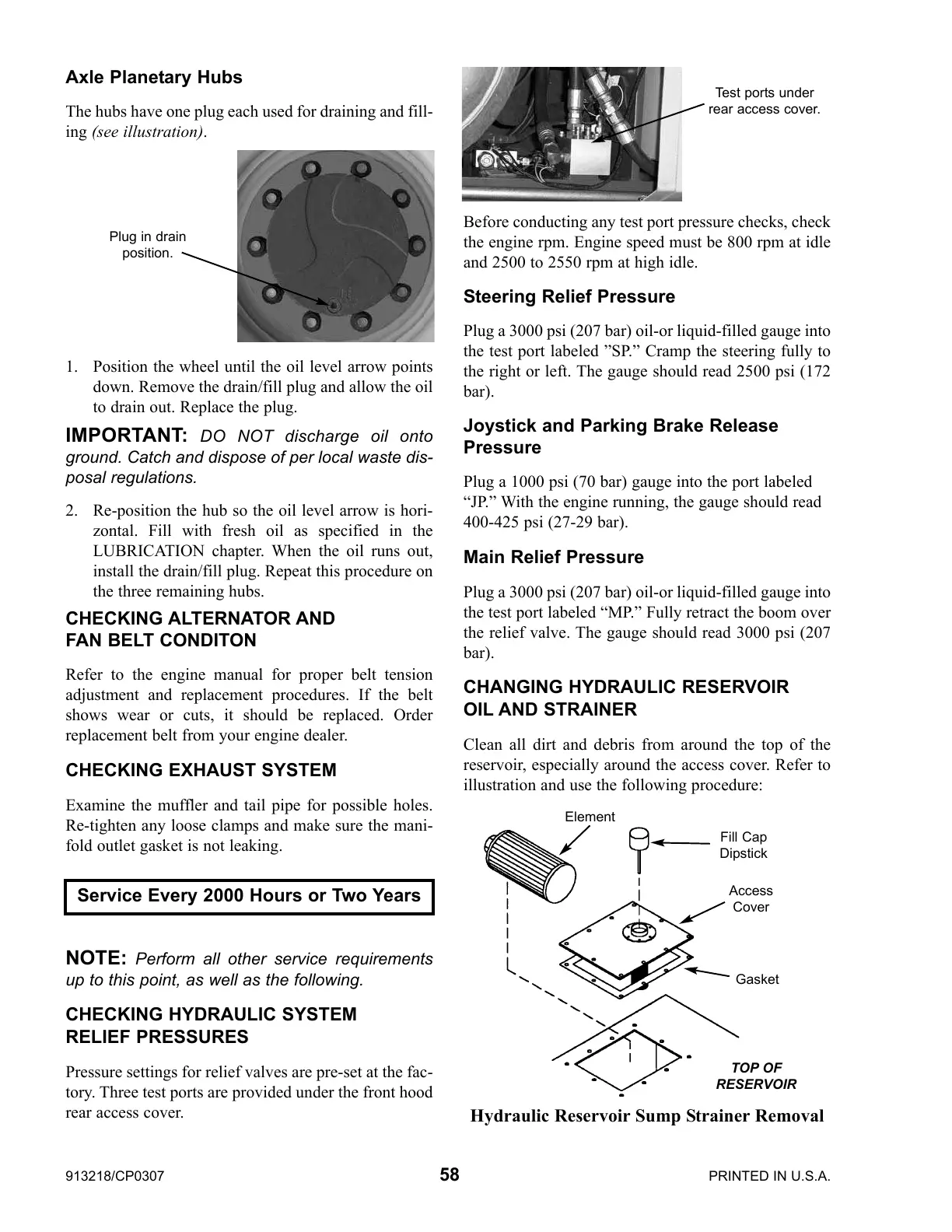

Axle Planetary Hubs

The hubs have one plug each used for draining and fill-

ing (see illustration).

1. Position the wheel until the oil level arrow points

down. Remove the drain/fill plug and allow the oil

to drain out. Replace the plug.

IMPORTANT: DO NOT discharge oil onto

ground. Catch and dispose of per local waste dis-

posal regulations.

2. Re-position the hub so the oil level arrow is hori-

zontal. Fill with fresh oil as specified in the

LUBRICATION chapter. When the oil runs out,

install the drain/fill plug. Repeat this procedure on

the three remaining hubs.

CHECKING ALTERNATOR AND

FAN BELT CONDITON

Refer to the engine manual for proper belt tension

adjustment and replacement procedures. If the belt

shows wear or cuts, it should be replaced. Order

replacement belt from your engine dealer.

CHECKING EXHAUST SYSTEM

Examine the muffler and tail pipe for possible holes.

Re-tighten any loose clamps and make sure the mani-

fold outlet gasket is not leaking.

NOTE: Perform all other service requirements

up to this point, as well as the following.

CHECKING HYDRAULIC SYSTEM

RELIEF PRESSURES

Pressure settings for relief valves are pre-set at the fac-

tory. Three test ports are provided under the front hood

rear access cover.

Before conducting any test port pressure checks, check

the engine rpm. Engine speed must be 800 rpm at idle

and 2500 to 2550 rpm at high idle.

Steering Relief Pressure

Plug a 3000 psi (207 bar) oil-or liquid-filled gauge into

the test port labeled ”SP.” Cramp the steering fully to

the right or left. The gauge should read 2500 psi (172

bar).

Joystick and Parking Brake Release

Pressure

Plug a 1000 psi (70 bar) gauge into the port labeled

“JP.” With the engine running, the gauge should read

400-425 psi (27-29 bar).

Main Relief Pressure

Plug a 3000 psi (207 bar) oil-or liquid-filled gauge into

the test port labeled “MP.” Fully retract the boom over

the relief valve. The gauge should read 3000 psi (207

bar).

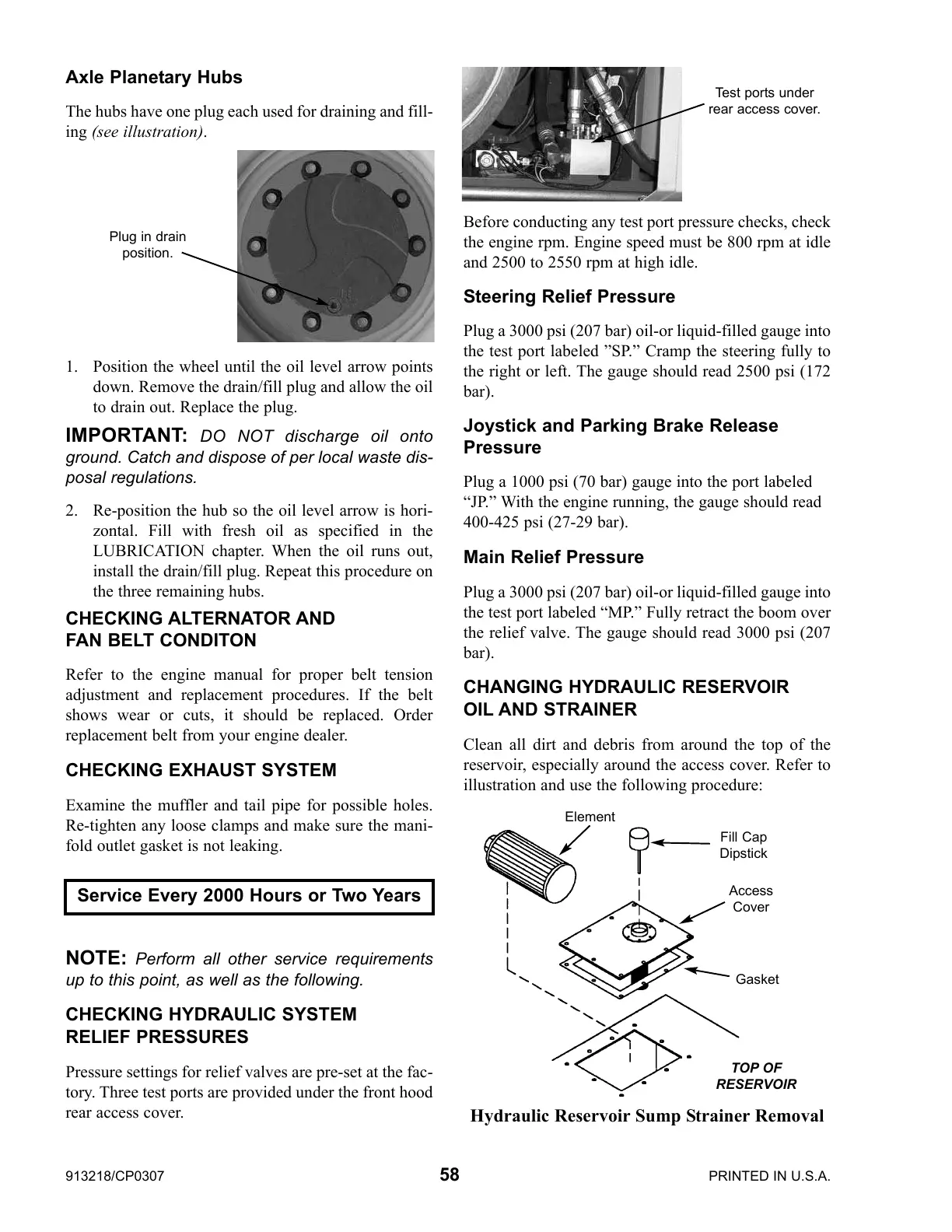

CHANGING HYDRAULIC RESERVOIR

OIL AND STRAINER

Clean all dirt and debris from around the top of the

reservoir, especially around the access cover. Refer to

illustration and use the following procedure:

Hydraulic Reservoir Sump Strainer Removal

Element

TOP OF

RESERVOIR

Service Every 2000 Hours or Two Years

Test ports under

rear access cover.

Plug in drain

position.

Gasket

Access

Cover

Fill Cap

Dipstick

Loading...

Loading...