Generac

®

Power Systems, Inc. 5

1.8 ADJUSTING THE LOAD BLOCK

When the natural gas system is being used, the load

block is fitted with an adjustment screw that has

been calibrated to provide maximum power.

However, because of variations in the Btu content of

natural gas across the country, it may be necessary to

readjust the load block.

• Connect a frequency meter to the output of the gen-

erator.

• Start the unit and apply full load according to the

following chart:

• Allow the unit to stabilize; then, turn the adjust-

ment screw slowly clockwise or counterclockwise

and watch the frequency.

• When the highest frequency is reached, turn the

adjustment screw counterclockwise 1/4 turn.

• The fuel system is now set.

• For LP gas operations, the hose and blanking plug

must be reconfigured as shown in Figure 1.4, (Page

7) of the owner’s manual. The unit is set to provide

maximum power using LP gas.

Do not make any unnecessary adjustments.

Factory settings are correct for most applica-

tions. However, when making adjustments, be

careful to avoid overspeeding the engine.

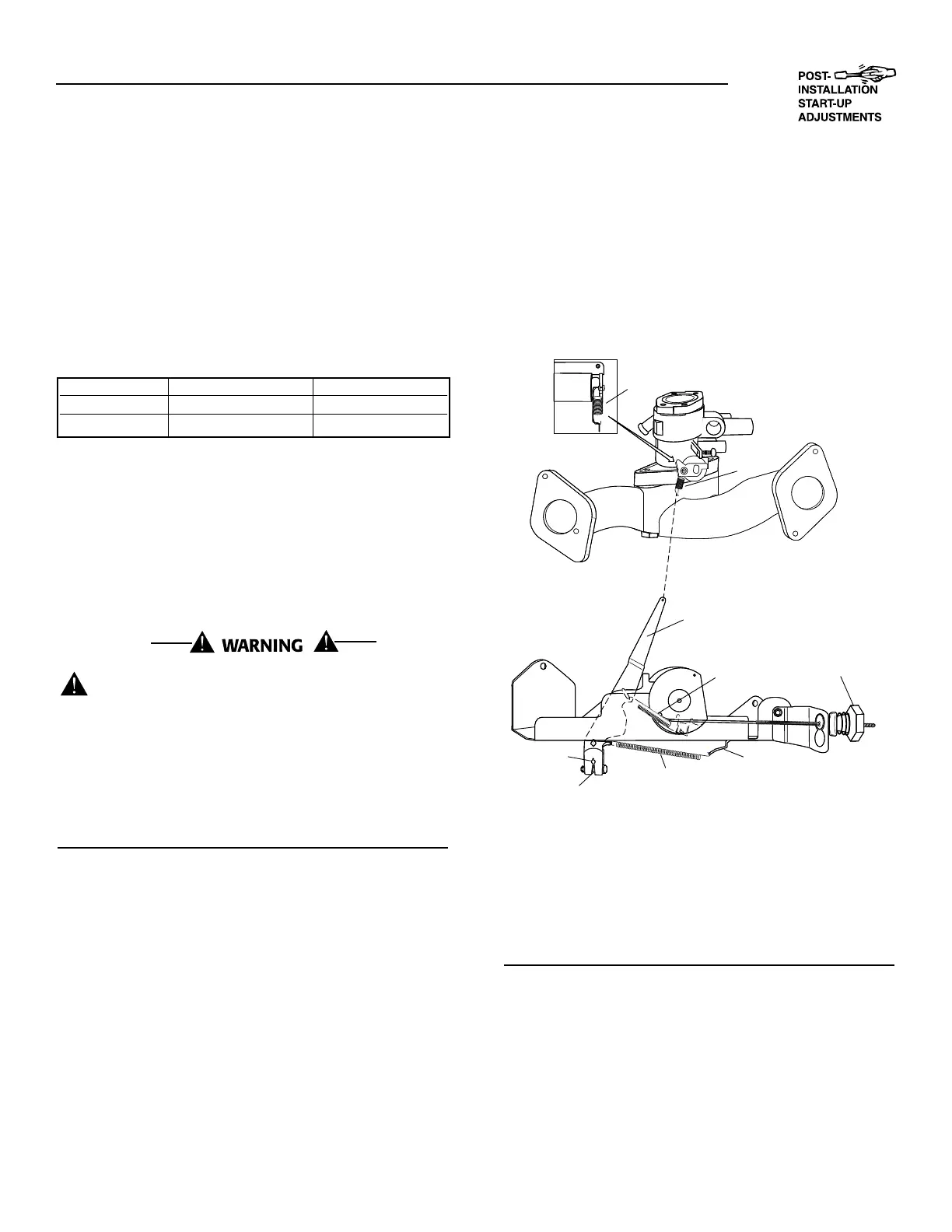

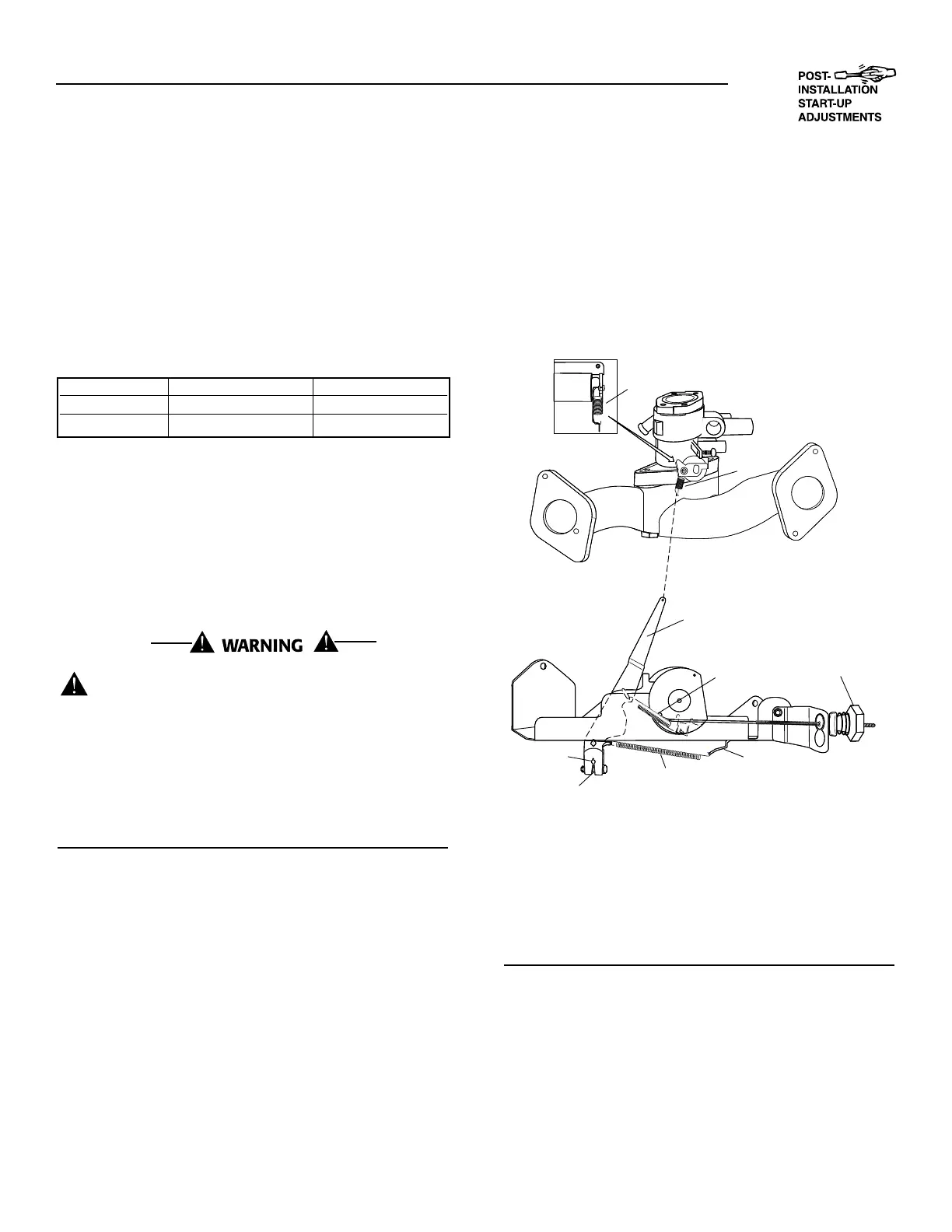

1.9 ENGINE GOVERNOR ADJUSTMENT

If both AC frequency and voltage are correspondingly

high or low, adjust the engine governor as follows:

1.9.1 8 KW AND 10 KW UNITS

1. Loosen the governor clamp bolt (Figure 1.3).

2. Push the spring end of the governor lever clock-

wise to the wide open throttle position of

the lever.

• Hold the governor lever at wide open throttle and,

with a screwdriver, rotate the governor shaft fully

clockwise.

• Before tightening, verify that the governor lever is

pushed all the way onto the governor shaft.

• While holding the governor shaft fully clockwise

and the governor lever at wide open throttle,

tighten the governor clamp bolt to 130 inch-

pounds (8 N-m).

3. Start the engine; let it stabilize and warm up at

no-load.

4. Turn the speed adjust nut to obtain a frequency

reading of 62 Hertz.

5. When frequency is correct at no-load, check the

AC voltage reading. If voltage is incorrect, the volt-

age regulator may require adjustment.

Figure 1.3–8kWand10kW

Engine Governor Adjustment

NOTE:

If the engine continues to run fast, use a pair of

pliers to bend the bend tab clockwise to release

tension on the lower governor spring.

1.9.2 ADDITIONAL CORROSION PROTECTION

Periodically spray all engine linkage parts and brack-

ets with corrosion inhibiting spray such as WD-40 or

a comparable product.

◆

Loading...

Loading...