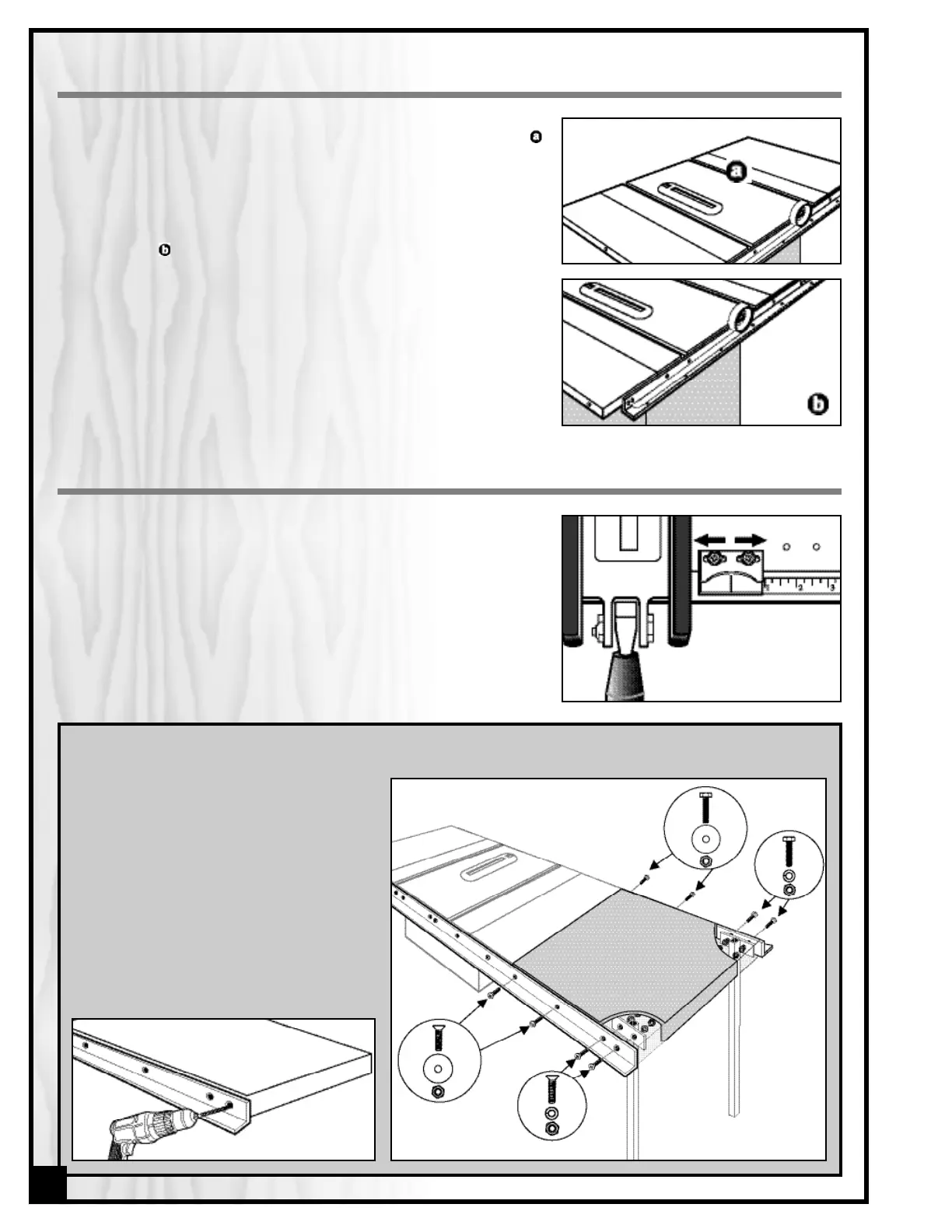

CHECK GUIDE TUBE FOR LEVEL

Note: In some rare instances, the top surface of the guide tube, on which

the fence slides, may not be parallel with the top of the saw table, .

This can result in friction when sliding the fence and eventual scraping

damage to the pointer and/or measuring tape.

To correct this situation:

1. Remove the guide tube.

2. Place 2 to 4 layers of masking tape along the back (or front) edge

of the rail, , as needed to shim up the guide tube.

3. Replace the guide tube and check for parallel.

If you find that the guide tube is out of parallel with the table top from

left to right, you should:

1. Refer back to Section II, loosen the screws on the front rail and use

the L-jig again to ensure that the rail is at proper height from

beginning to end.

2. Retighten the screws and replace guide tube.

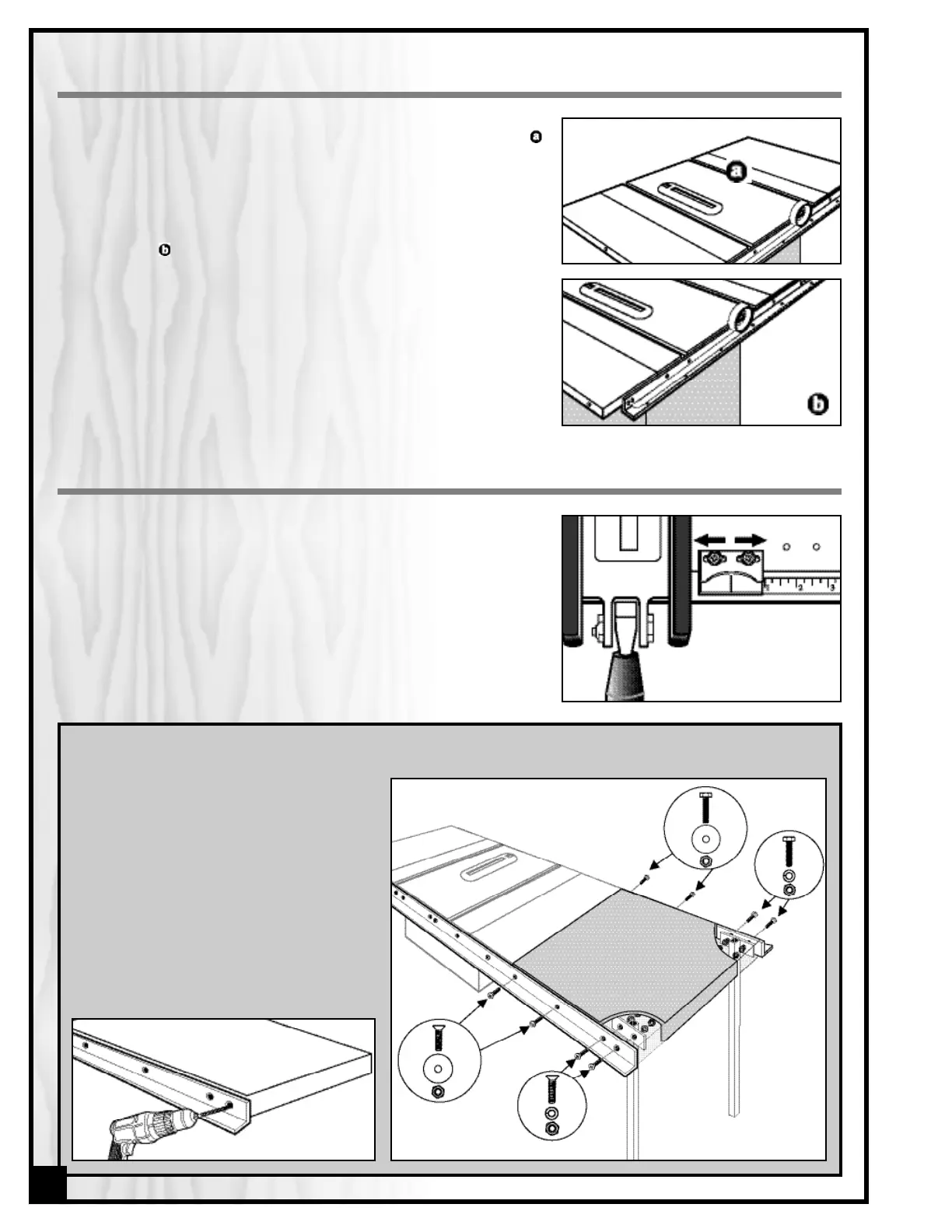

MAKE TEST CUTS TO CHECK POINTER ACCURACY

1. Once the measuring tape is installed and the fence is perfectly

parallel with the blade and table top,check the pointer’s center line

against the tape’s zero-point. If necessary, loosen the two screws to

slide the pointer left or right into position.

2. For the final check, slide the fence to the right so the pointer points

to the 2-inch mark. Use scrap wood to make several rips. If the cuts

don’t measure exactly 2 inches wide, readjust pointer.

INSTALLING A TABLE EXTENSION

Depending on your saw model and shop

needs you may wish to add an extension

table to your set-up. Whether supplied with

the unit, purchased aftermarket or shop

made, make sure the extension table fits

between the saw rails and can be installed

flush to the saw table. Clamp the extension

table in place on the rails, and using the

remaining holes on the rails as a guide, drill

two mounting holes front and back through

the table apron. Use the supplied washers

along with the spare bolts and nuts to secure

the extension table in place.

10

Loading...

Loading...