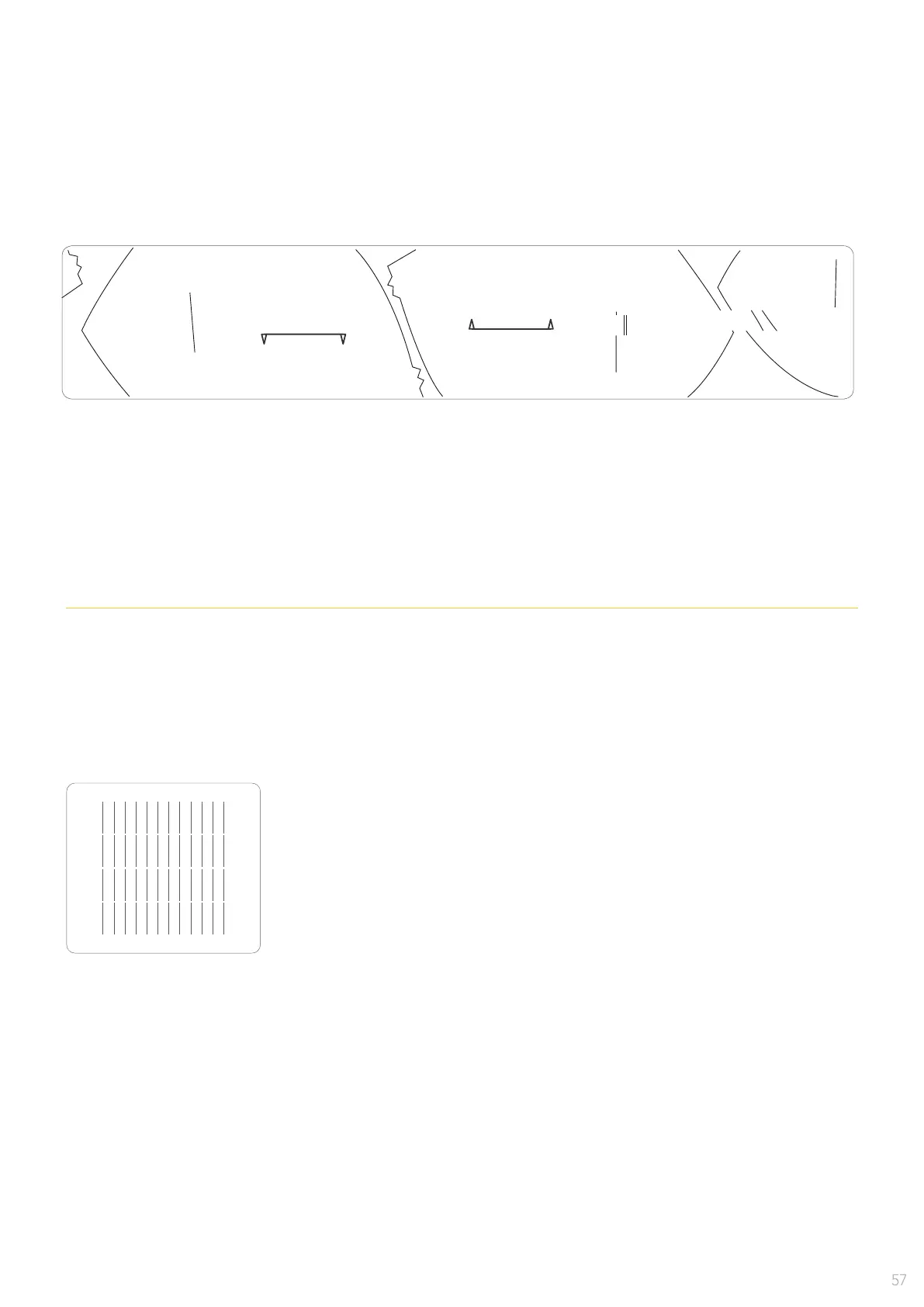

GAPS ON THE MARKER

If marker contains gaps between each printing movement means that paper is

not advancing properly. Can be due to:

1 -

Bad calibration. Repeat paper advance calibration.

2 - Brake pad eroded: check if the brake is eroded or bad adjusted (see

chapter 6 for procedure).

3 - Paper encoder is not counting well: we must verify that aluminum wheel of the encoder is in well

conditions, no hits, dirty... and turning ne, and the pressure wheel over it is touching completely at (no

light between upper bearing and aluminum wheel) and turning at the same time that paper advance.

4 - If following this procedure gaps are still there, consider to make a test with new encoder.

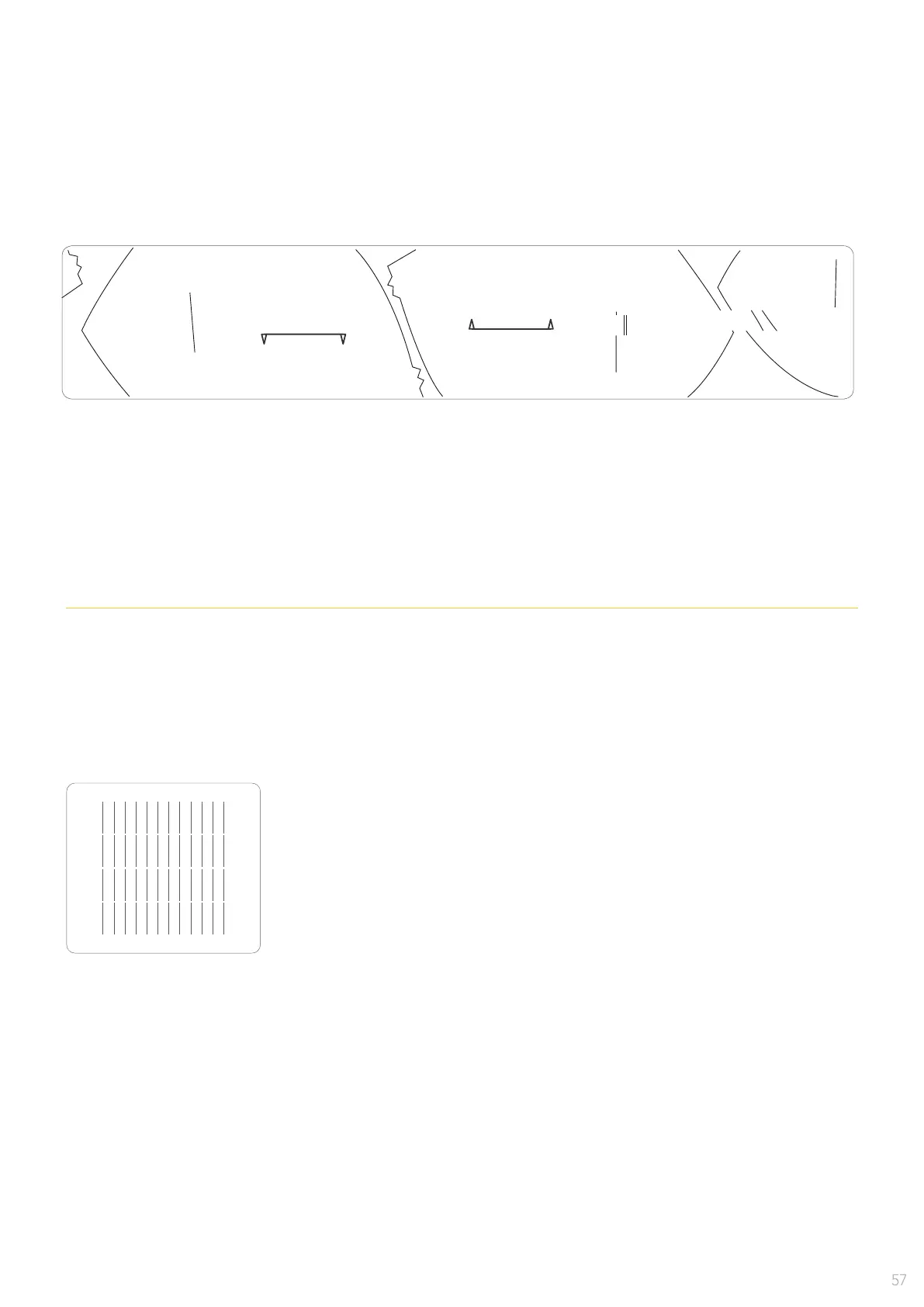

MISMATCHED LINES IN SIDES ONLY

If plotter have mismatched lines in the beginning of the printhead movement or

in the end of it, means some issue with the head driver cable or motor X pulley.

Note: This issue can also produce an "Overspeed" message. Check "Overspeed" in the movement alerts

chapter for more information.

1 - First check that head drive cable have the properly tension (metal spring plate appointing to the arrow

in the print head carriage body).

2 - Clean the driver cable with a tissue. It can’t contain oil, avoid the use of any lubrication.

3 - If tension is OK and cable clean, check that motor pulley is well tight (check the subjection screw).

PARERAFLOSS-1TEJ

T100

PARERAFLOSS-1TEJ

T100

Loading...

Loading...