3 2 1

N L

cylinder

control

C˚

immersion

heater

C˚

230 V AC

3 kW

1

1

3

2

2

4 4

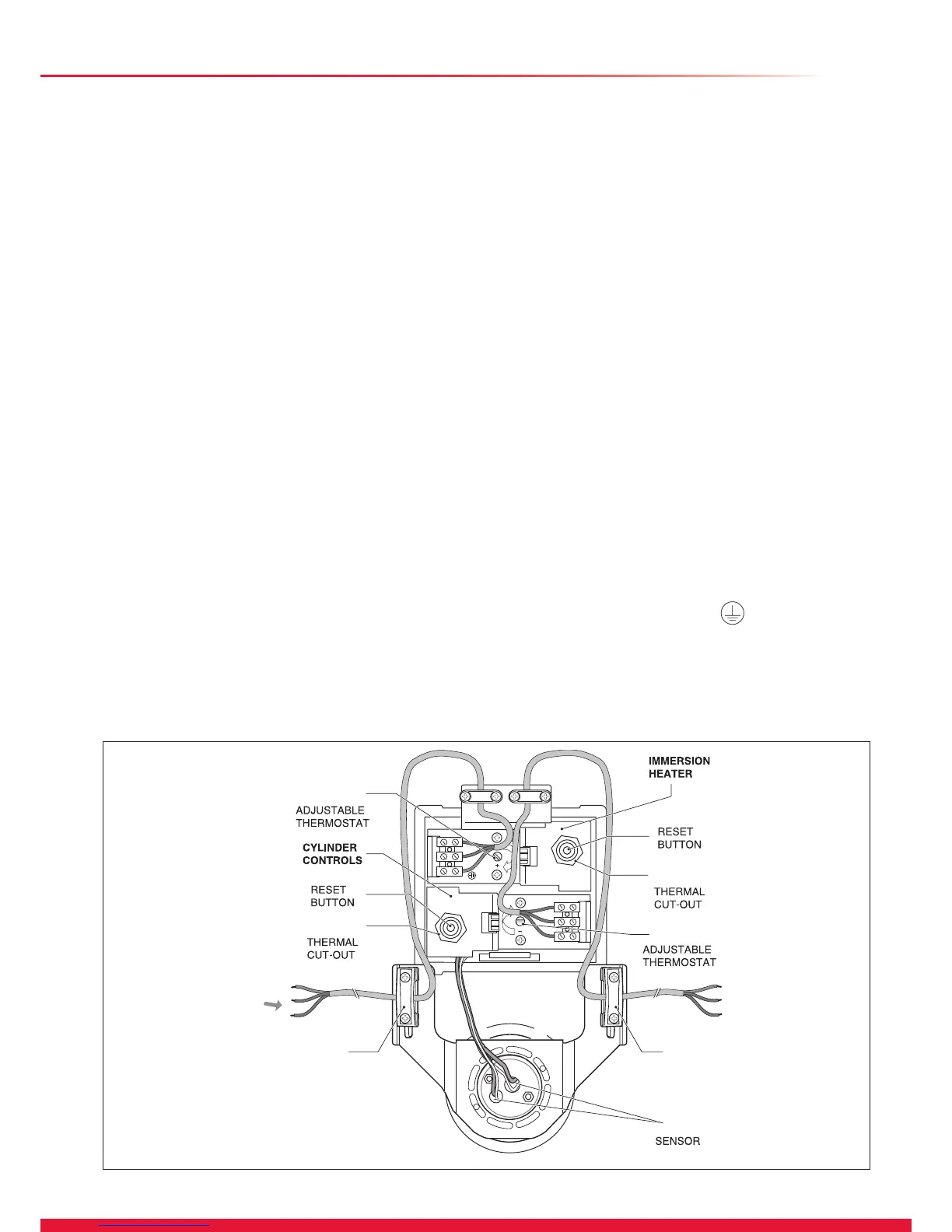

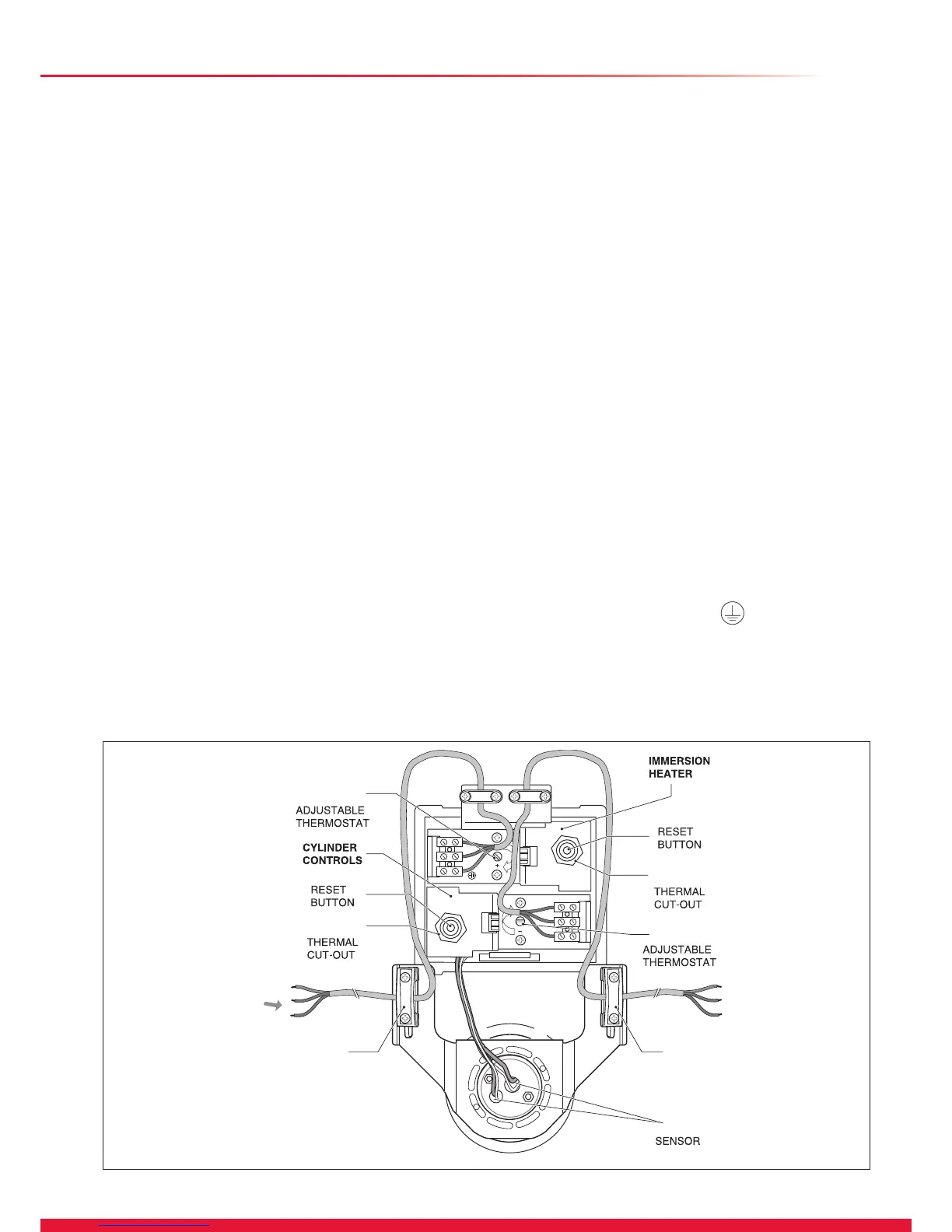

IMMERSION HEATER, ELECTRICAL CONNECTIONS

4 Installation

12557

4.10 Drain Valve

A drain valve has to be tted in the cold water mains supply

between the Glow-worm cylinder and the cold water control

valves as low as possible, see diagram 4.5.

We recommend to t a hose pipe in the outlet of the drain

valve approximately 1 metre below the bottom of the cylinder

(this can be achieved by connecting a suction hose to the

outlet of the drain valve).

4.11 Electrical connections and controls

All electrical connections conform to BS 7671.

NOTE: The position of the discharge pipes (tundish), drain

valves and motorised valves etc. shall be positioned away

from any electrical components.

4.12 Immersion Heater

WARNING: The immersion heater must be earthed.

IMPORTANT: The immersion heater incorporates an energy

cut-off device and must not under any circumstances be

replaced by a standard immersion heater.

Only a correct genuine Glow-worm spare part is permitted.

The Glow-worm 115 - 300 cylinders are equipped with a

factory tted immersion heater.

All internal wiring is factory tted.

Install a separate electrical supply to the immersion heater in

accordance with the current IEE wiring regulations (BS 7671).

The immersion heater must be wired in 2.5 mm

2

heat-resisting

cable from a double pole isolating switch. The circuit must be

protected by a 13 amp fuse. The connection details for the

immersion heater are shown in diagram 4.8.

4.13 Electrical Connections and Controls

WARNING: The Glow-worm cylinder must be earthed.

The Glow-worm cylinder and accompanying boiler may be

controlled using various programmers and room thermostats,

details of which are given in section: Control Options.

The Glow-worm cylinder has a factory tted cylinder thermal

cut-out, thermostat and manual reset.

Diagram 4.8

IMPORTANT: Before resetting the thermal cutout or changing

the temperature setting of the thermostat, switch the electrical

supply off.

All internal wiring is factory tted.

The thermostat which controls the DHW temperature (see 1,

diagram 4.8) is adjustable between 20 and 65°C. The built in

safety thermal cut out operates at 90°C. Should the thermal

cut out be brought into operation, the motorized 2 port valve

will operated and shut the primary ow to the cylinder. Press

the reset button, see diagram 4.8 to reset thermal cut out and

motorised valve.

Connections to wiring centre

Remove the screw from the front panel.

Provide a wiring centre adjacent to the cylinder to make the

electrical connections.

Ensure that the cables are xed in the cord grip (see 4,

diagram 4.8).

Connect the Glow-worm boiler terminals to the corresponding

terminals of the wiring centre.

Connect the Glow-worm cylinder controls and the 2 port valve

ying lead to the terminals of the wiring centre.

Connect the terminals of the programmer and room

thermostat to the terminals of the wiring centre.

Connect a 3 amp fused mains supply to the terminals of the

wiring centre.

NOTE: All wiring must be carried out in accordance with

the current BS 7671 and the requirements for electrical

installations.

Check that the cylinder thermostat and immersion heater

sensors are correctly positioned in the tubes.

If you do not use the immersion heater then connect an

earth wire to the terminal marked

on the immersion

heater connector block.

13

Loading...

Loading...