4

General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

gled wraps, remove several feet of improperly wrapped rope and rewind, under tension, prior to

starting the actual pull. To insure good operation, the wraps and lays must always be straight

and compact.

The winch is furnished with a caliper type drag brake. The brake is not designed to hold the load.

The purpose of the brake is to control the drum rotation speed when paying out wire rope under

free spool conditions. Slowing down and gradually stopping the drum, with tension on the rope,

will prevent backlash, clock-springing and eventual entanglement of the rope.

For safety and convenience, the drag brake is equipped with a remote actuator. The remote ac-

tuator, reservoir and flexible hose section are shipped loose in the parts box. These components

are to be installed by the dealer.

Although the level wind will guide the wire rope onto the drum from a relatively wide fleet angle,

there will be less bending of the rope at the roller cage assembly if the line of pull is as straight

as possible. Therefore, the use of a universal or universal swivel sheave on the tail shelf is advis-

able.

The roller cage assembly has only a sufficient amount of clearance for the rope to pass. When

pulling in the wire rope, it is important that the operator stops the drum rotation at a point to keep

the spliced eye or quick hook several feet from the roller cage. Otherwise, the eye and hook will

be drawn into the roller cage, causing damage to the level wind.

If, for any reason, it is necessary to remove the wire rope from the roller cage while at a mid-

point in the rope, it can be done by removing the roller cage top plate. First, remove the (2) hex

bolts on the roller cage top plate then remove the top plate. Loosen the (2) set screws on either

side of the mounting plate and remove the roller guide. The rope is then free.

4. Placing Wire Rope Onto The Winch Drum

Note: See section 8.0 for additional details on wire rope.

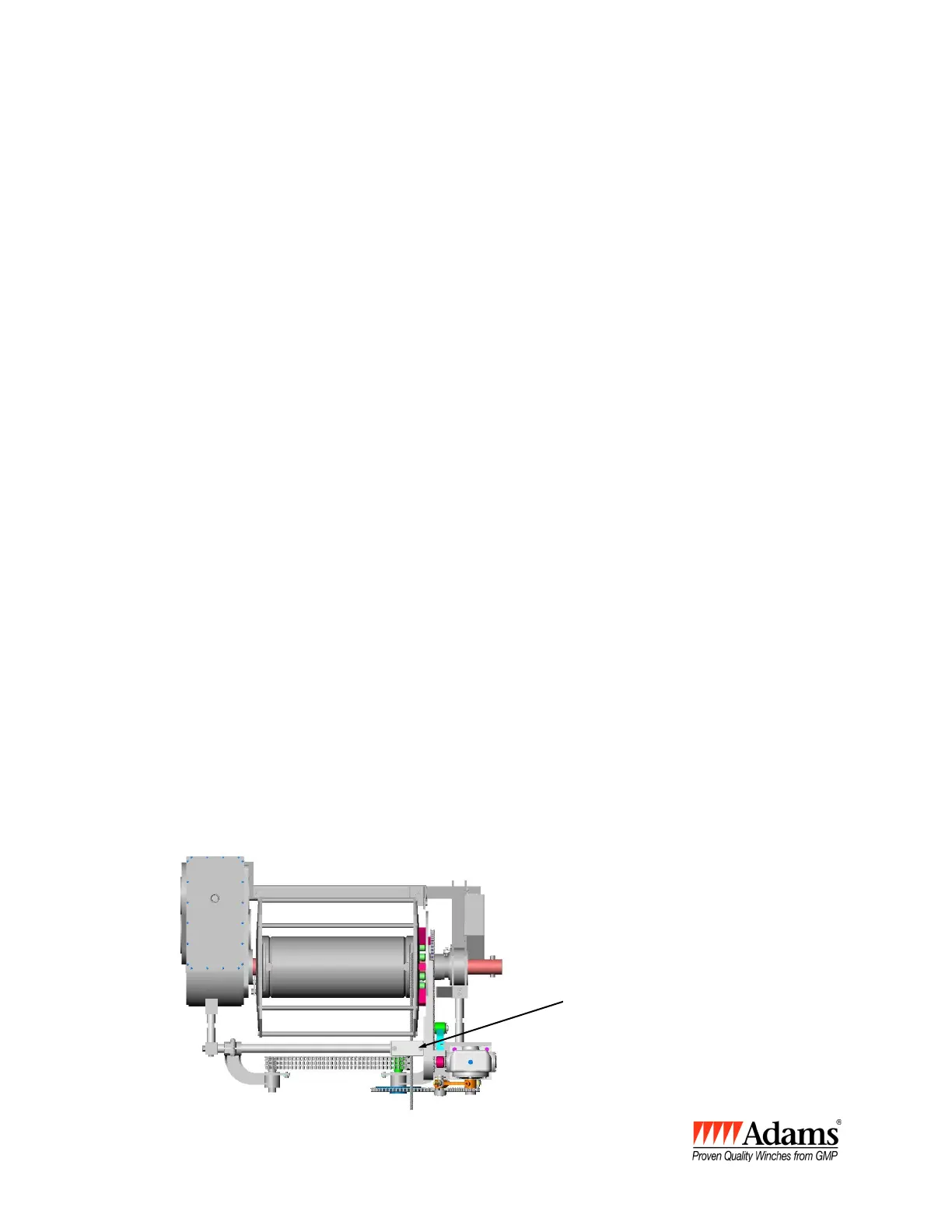

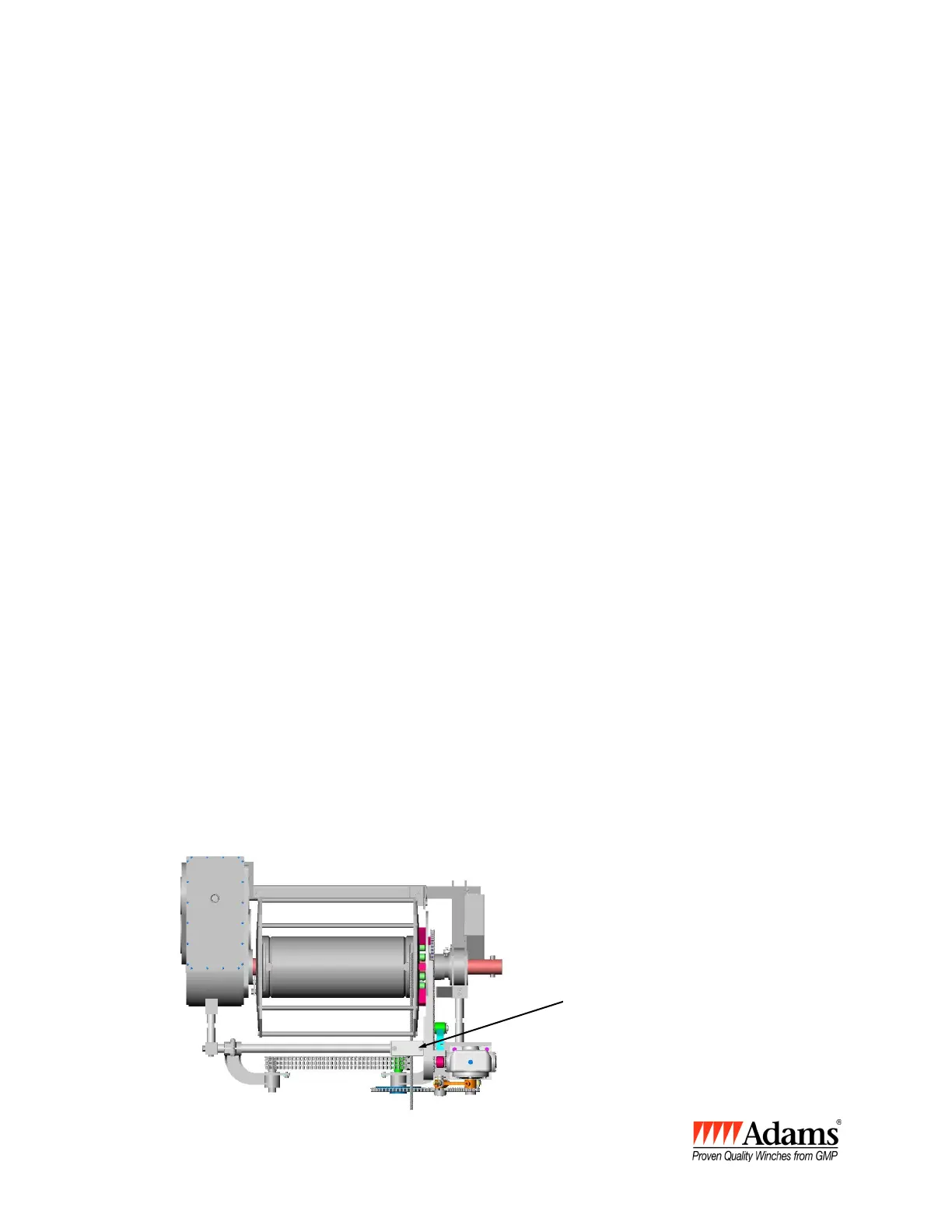

The timing of the level wind must be set properly when placing rope onto the drum. Set the tim-

ing of the level wind by rotating the drum until the carriage reaches a position of maximum travel

at the drum end where the rope is to be attached. The extreme end of the carriage travel is when

the guide link is on the outside of the end sprocket and at the mid-point of the vertical slot in the

carriage. Thread the end of the rope through the roller cage and attach it to the drum by means

of the rope clamp. See figure 2. Drive the winch forward at a low speed, keeping sufficient ten-

sion on the rope. It is extremely important that the first lay of rope be straight and compact. Slow-

ly increase the drum speed and spool on the remaining rope.

Whenever possible, a winch line holder should be used to prevent the rope from unwinding.

5. Adjustment

The speed reducer input and

The carriage at the

maximum travel position

Figure 2.

Loading...

Loading...