MAINTENANCE

ASSEMBLY /

INSTALLATION

SAFETY /

SPECIFICATIONS

GETTING STARTED

10

EN

OPERATION

OPERATION

Always follow safety precautions when operating this

equipment. Review the General Safety Instructions at

front of manual.

IMPORTANT: Before each use, visually check the meter to ensure it is

securely connected to other system components and there is no leakage.

Promptly wipe spilled fuel from the meter’s exterior and other system

components.

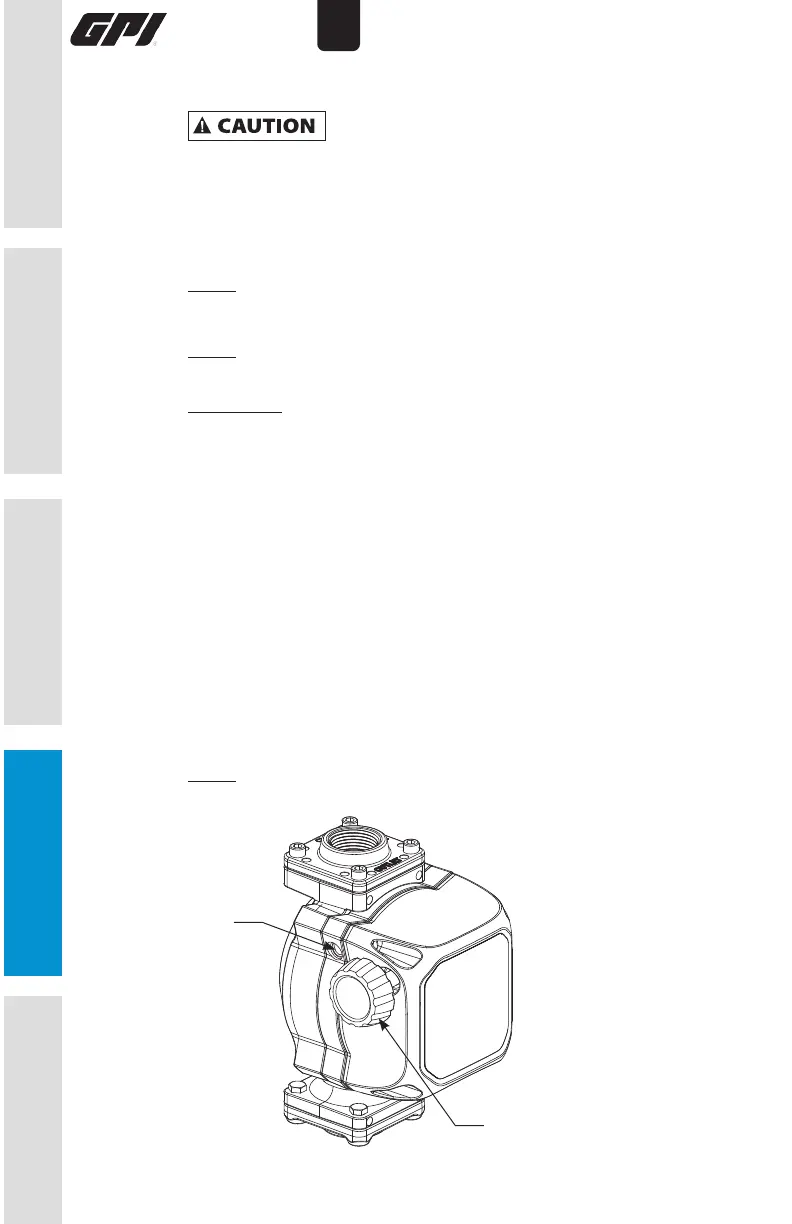

NOTE: The large meter display represents the Batch Total for each fuel

delivery. Before dispensing, reset the Batch Total to zero by turning the

knob (see Figure 5)

NOTE: The small display represents the Cumulative Total of all fuel

deliveries and cannot be reset.

Calibration

The Calibration Screw is located on the side of the meter (see Figure 6) and

can be adjusted with a 3mm hex wrench. The meter is accurately calibrated

at the factory for use with diesel fuel. In the event the screw is accidentally

moved, the meter will need to be recalibrated. To recalibrate the meter for

diesel fuel, turn the screw completely in (clockwise) then back out (counter-

clockwise) 3 turns.

To recalibrate the meter for gasoline, turn the screw completely in

(clockwise). The Cal-screw does not need to be turned back out for

gasoline.

Due to differences in viscosity and flow rates, the meter may require

recalibration to measure other fluids or to adjust for inaccuracies.

In general, if the register indicates less than what is dispensed, the

Cal-Screw needs turned in; if the register indicates more than what was

dispensed, the Cal-Screw needs turned out.

NOTE: Never back the Cal-Screw out more than 12 turns from completely

closed. Doing so could inhibit the seal resulting in leaking.

Figure 5

Cal-Screw

Register

Knob

Loading...

Loading...