ROUTINE MAINTENANCE

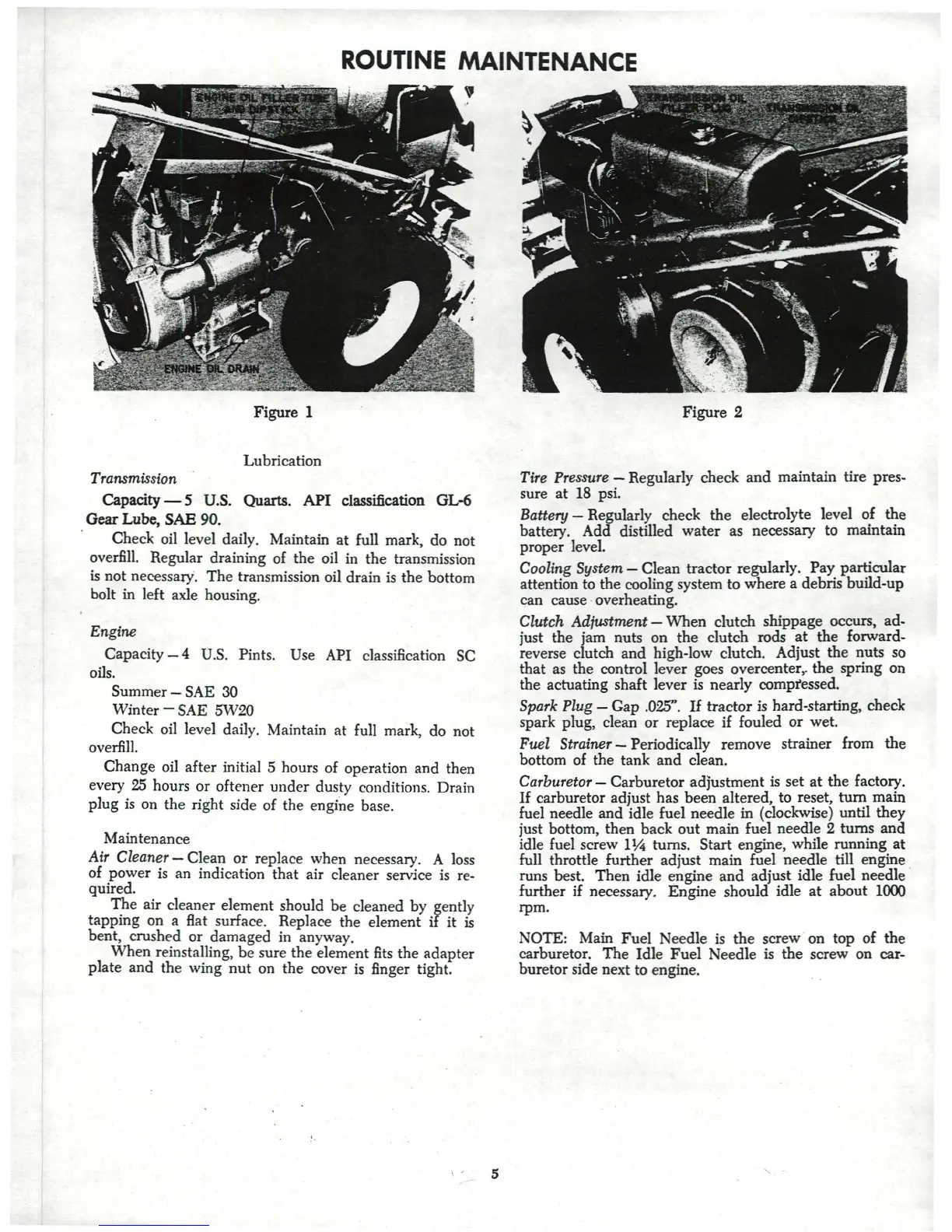

Figure 1

Lubrication

Transmission

Capacity - 5

U.S.

Quarts.

API

classification GL-6

Gear Lube, SAE 90.

Check oil level daily. Maintain

at

full mark, do not

overfill. Regular draining of the oil in the transmission

is

not necessary'.

The

transmission oil drain

is

the bottom

bolt in left axle housing.

Engine

Capacity - 4

U.S.

Pints. Use API classification

SC

oils.

Summer - SAE 30

Winter - SAE 5W20

Check oil level daily. Maintain

at

full mark, do not

overfill.

Change oil after initial 5 hours of operation and then

every

25

hours or oftener under dusty conditions. Drain

plug

is

on the right side of the engine base.

Maintenance

Air Cleaner

- Clean or replace when necessary. A loss

of power

is

an indication that air cleaner service

is

reo

quired.

T.he

air cleaner element should be cleaned by gently

tappmg on a flat surface. Replace the element

if

it

is

bent, crushed or damaged in anyway.

When reinstalling, be sure the element

fits

the adapter

plate and the wing

nut

on the cover

is

finger tight.

\ .

5

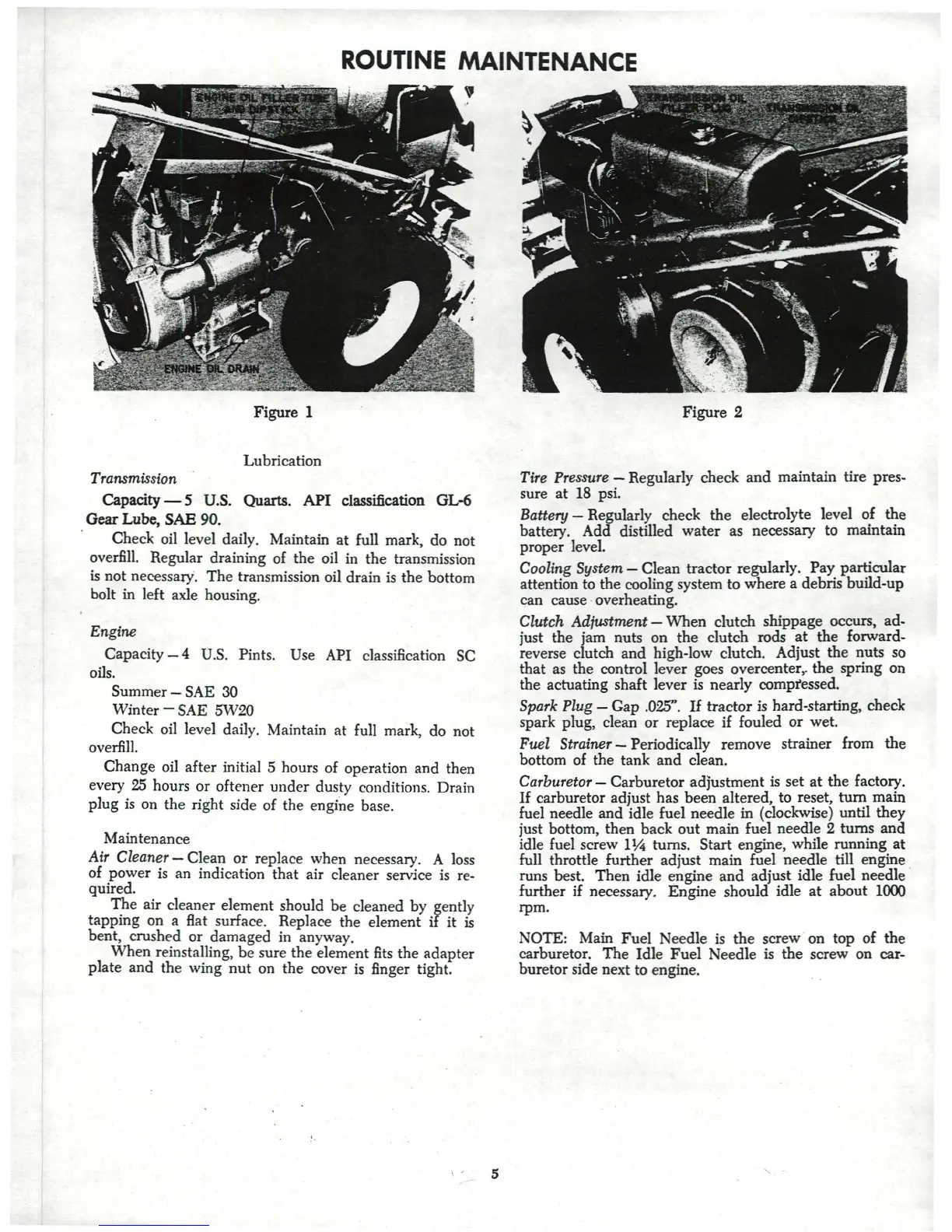

Figure 2

Tire Pressure - Regularly check and maintain tire pres.

sure

at

18

psi.

Battery - Regularly check the electrolyte level of the

battery. Add distilled water as necessary to maintain

proper level.

Cooling System - Clean tractor regularly. Pay particular

attention to the cooling system to where a debris build-up

can cause· overheating.

Clutch Ad;ustment-

When

clutch shippage occurs, ad.

just the jam nuts on the clutch rods

at

the forward-

reverse clutch and high-low clutch. Adjust the nuts

so

that

as

the control lever goes overcenter,. the spring on

the actuating shaft lever

is

nearly compressed.

Spark Plug - Gap .025".

If

tractor is hard-starting, check

spark plug, clean or replace if fouled or wet.

Fuel Strainer

- Periodically remove strainer from the

bottom of the tank

and

clean.

Carburetor - Carburetor adjustment

is

set

at

the factory.

If

carburetor adjust has been altered, to reset,

tum

main

fuel needle and idle fuel needle in (clockwise) until they

just bottom, then back

out

main fuel needle 2 turns and

idle fuel screw

IV-i

turns. Start engine, while running

at

full throttle further adjust main fuel needle till engine.

runs best. Then idle engine

and

adjust idle fuel needle

further if necessary. Engine should idle

at

about 1000

rpm.

NOTE: Main Fuel Needle

is

the screw' on top of the

carburetor.

The

Idle

Fuel

Needle

is

the screw on car-

buretor side next to engine.

'-

.

Loading...

Loading...