and two

35mm

nuts.

4.

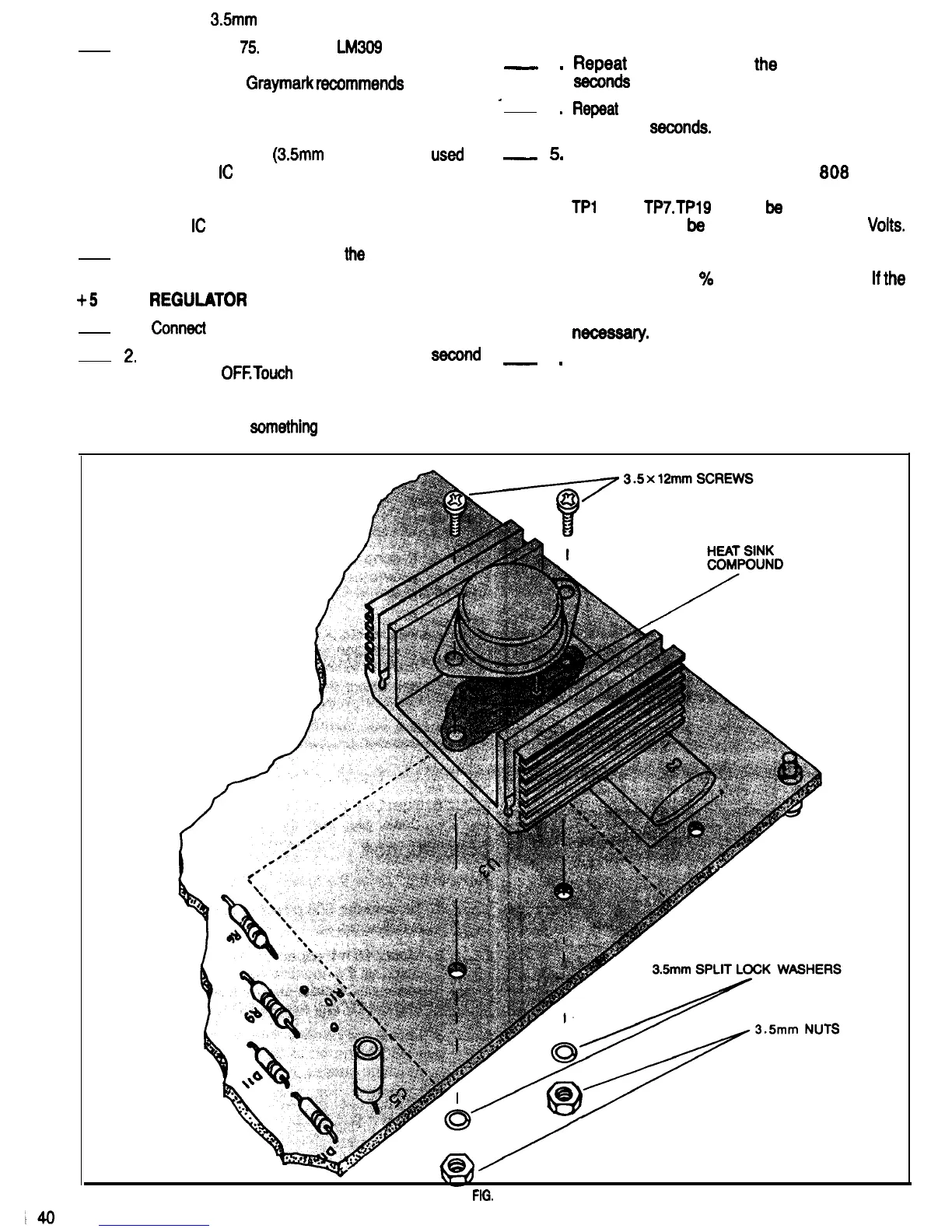

Refer to Fig.

75.

Mount the

LM3OQ

regulator and

heat sink on the PCB, using the hardware called

-

3

.

out in step 3.

Graymark

r8commends

the use of

heat sink compound on the surfaces of the

’

voltage regulators and heat sinks where they

4

.

contact each other. Be sure that the larger

machine screws

(35mm

diameter) are

us8d

to

-

5

.

fasten the

IC

and heat sink to the PCB. If you use

the smaller 3mm diameter screws for this

purpose, it is possible for the heat sink to short

to the

IC

leads.

5.

Solder the regulator leads to

the

PCB. Cut off any

excess lead length.

+5

VOLT

REGUMTOR

TEST

1.

Conn8ct

th8 808 power plug to a power outlet.

2.

Turn th8 808 power switch ON, wait 1

s8cond

-

6

.

and turn it

OFETouch

the components that were

installed in the construction steps that were just

completed. If any of these components are

warm, there is

sumething

wrong. Check the PCB

and components carefully, and consult with your

instructor if necessary.

Repeat

step 2, leaving

the

power ON for 5

s8conds

this time.

Rep8at

step 2 again, this time leaving the power

ON for 15

seconds.

If none of the components heated up in the

previous steps, power up the

808

again.

Measure the dc voltage between* test points

TPi

9 and

TP7.TPlQ

should

be

positive, and the

voltage should

be

between 4.6 and 5.4

Volts.

This range of voltages allows for the specified

output voltage tolerance (4.7 to 5.3 Volts), plus

approximately 2

%

measurement error.

lf

the

voltage is not in this range, check your work

carefully, and consult with your instructor if

n8cessarym

Turn OFF the 808 power switch and remove the

power plug from the power outlet.

FIG.

75

Loading...

Loading...