GMV DC Inverter VRF

52

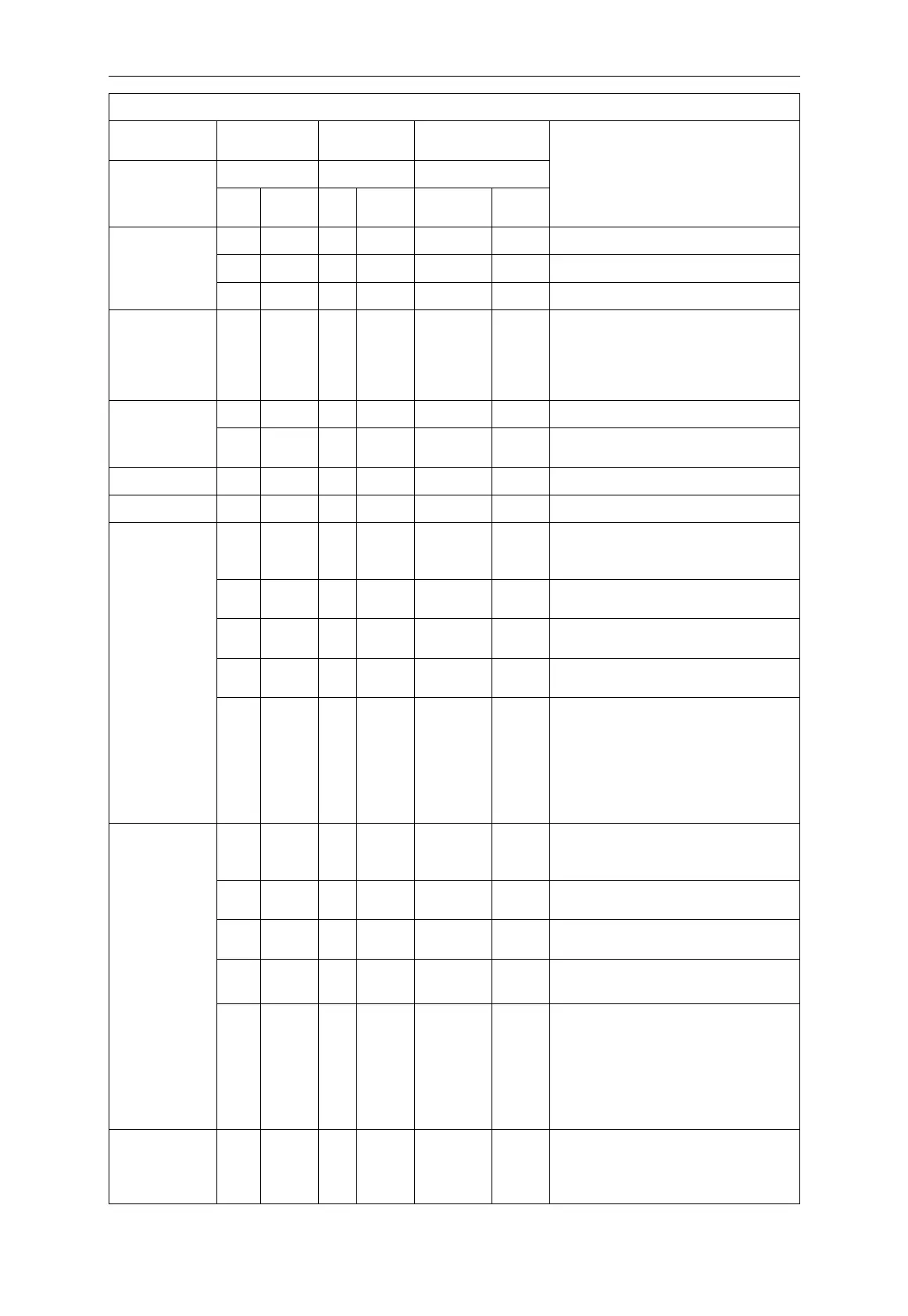

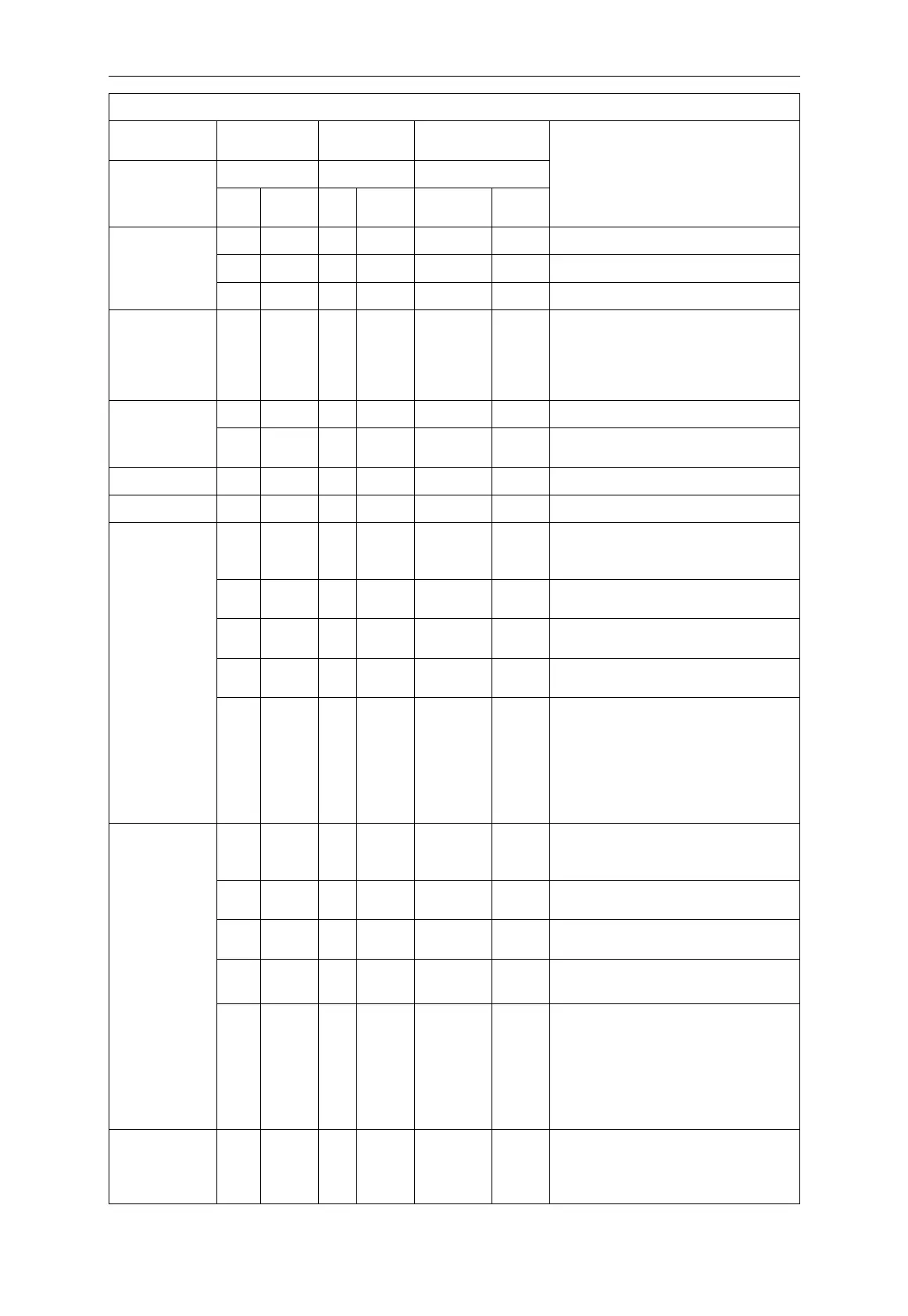

Description of each stage of debugging progress

10_Status

judgments of

outdoor valves

before startup

Outdoor valves are being turned on.

Outdoor valves are not fully turned on.

Outdoor valves are turned on normally.

11_Calculate

refrigerant

quantity

manually

Calculate the refrigerant quantity

manually and confirm the perfusion

status of refrigerant (the quantity of

refrigerant added into the system must

be recorded accurately).

12_Confirm

debugging

startup

Ready for units to start debugging.

Manual calculation of refrigerant

quantity is set up.

Debugging is enabled in cooling mode

(debugging mode, auto-selected by

system).

Error occurs during debugging in

cooling mode.

Error of other modules occurs during

debugging in cooling mode.

Outdoor pipeline and valves are not

normal.

System detects error in indoor pipeline.

XXXX is the project no. of the faulted

IDU. 3s later, error code U8 is

displayed. For example, IDU no. 100

has U8 error, then LED3 displays like

this: 01 (2s later) 00 (2s later) U8, and

repeat again.

Debugging is enabled in heating mode

(debugging mode, auto-selected by

system).

Error occurs during debugging in

heating mode.

Error of other modules occurs during

debugging in heating mode.

Outdoor pipeline and valves are not

normal.

System detects error in indoor pipeline.

XXXX is the project no. of the faulted

IDU. 3s later, error code U8 is

displayed. For example, IDU no. 100

has U8 error, then LED3 displays like

this: 01 (2s later) 00 (2s later) U8, and

repeat again.

Debugging is finished. System is on

standby condition. LED1 displays

module address. LED2 and LED3

display “OF”.

Loading...

Loading...