2

2

■

■

Installation notice

■

■

■

7

■

■

8

12

3

9

4

13

5

6

■

14

To ensure safety, please be mindful of the

following precautions.

10

11

WARNING

Screw driver

Impact drill

Open-end

Pipe cutter

wrench

detector

Vacuum pump

Leakage

Pressure meter

Level meter

tape

Measuring

meter

Please contact the local agent for installatio n.

Don’t use unqualified power cold.

spanner

Universal

Inner hexagon

When refrigerant needs to be recovered

during relocating or repairing the unit, be

Drill head

NOTICE

●

●

Electric wires with insufficient capacity, wrong

wire connections and insecure wire terminals

may cause electric shock or fire.

Pipe expander

Torque wrench

When installing the unit, make sure that co-

nnection pipe is securely connected before

the compressor starts running.

If compressor starts running when stop valve

is open and connection pipe is not yet conne-

cted, air will be sucked in and cause pressure

rise or compressor rupture, resulting in injury.

1 minute.

When installing or relocating the unit, be s-

ure to keep the refrigerant

circuit free from

air or substances other than the specified

refrigerant.

Any presence of air or other foreign substance

in the refrigerant circuit will cause

system pre-

ssure rise or compressor rupture, resulting

in injury.

When in

stalling or moving this unit, do not

charge the refrigerant which is not comply

with that on the nameplate or unqualified

refrigerant.

Otherwise, it may cause abnormal operation,

wrong action, mechanical malfunction or even

serious safety accident.

Tools for installation

5

Safety precautions for installing and

relocating the unit

sure that the unit is running in cooling mode.

Then, fully close the valve at high pressure

side (liquid valve). About 30-40 seconds later,

fully close the valve at low pressure side

(gas valve), immediately stop the unit and

disconnect power. Please note that the time

for refrigerant recovery should not exceed

Use the specified types of wires for electrical

connections between the indoor and outdoor

units. Firmly clamp the wires so that their te-

rminals receive no external stresses.

Prohibit installing the unit at the place where

there may be leaked corrosive gas or flamm-

able gas.

If there is leaked gas around the unit, it may

cause explosion and other accidents.

WARNING

Do not use extension cords for electrical co-

nnections. If the electric wire is not long eno-

ugh, please contact a local service center au-

If refrigerant recovery takes too much time,

air may be sucked in and cause pressure

rise or compressor rupture, resulting in injury.

During refrigerant recovery, make sure that

liquid valve and gas valve are fully closed

and power is disconnected before detachi-

ng the connection pipe.

If compressor starts running when stop valve

is open and connection pipe is not yet conn-

ected, air will be sucked in and cause pressure

rise or compressor rupture, resulting in inju

ry.

thorized and ask for a proper electric wire.

Poor connections may lead to electric shock or fire.

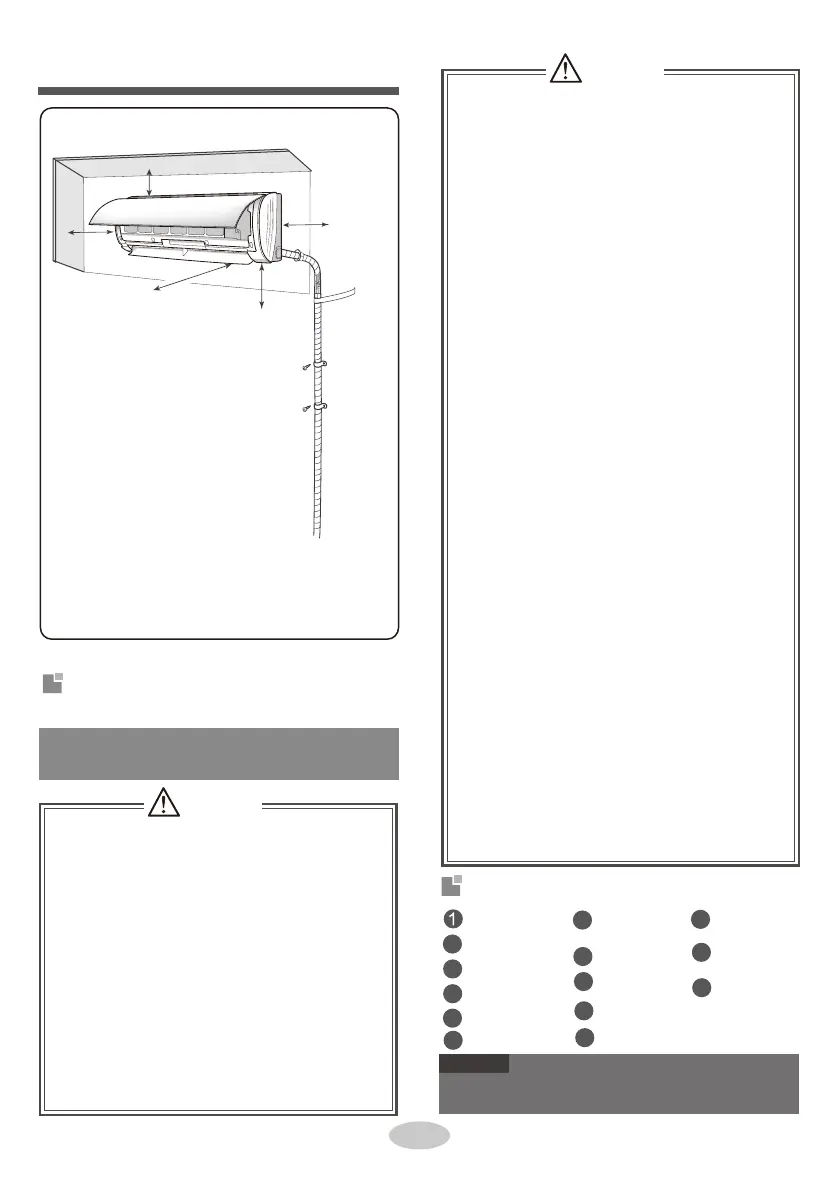

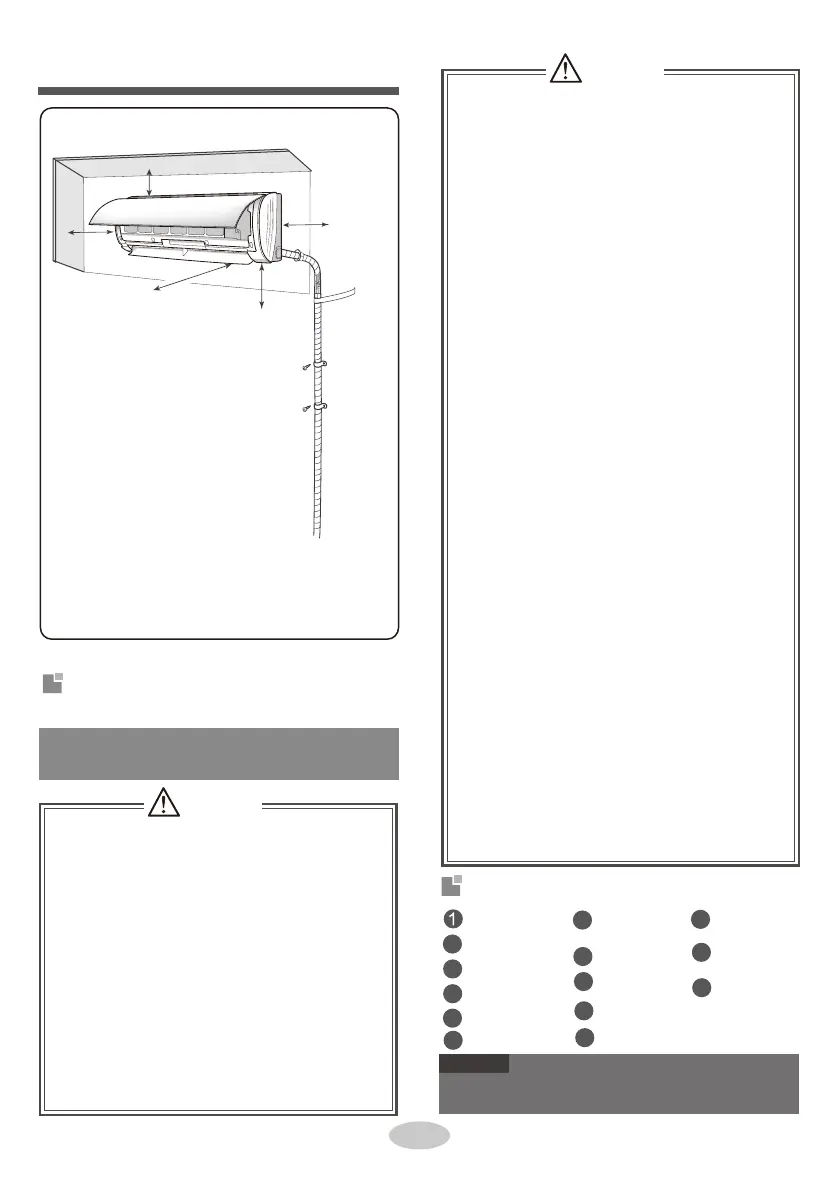

At least 15cm

A

At least 250cm

e ceilingSpac

Space to the wall

e to th

t least 15cm

At least 15cm

Space to the wall

At least 300cm

Space to the obstruction

Space to the floor

Loading...

Loading...