:

?

;(t

Cutter

Deck

:

r'

i

Regularly

check

the condition of

the cutter blades and blade bolts, the cutter disc, V belt and

pulleys

and the cutter brake.

Refer to

specific

sections

in this book for further details

regarding

blades, V belts etc.

ureanrng

Never wash

your

Greenfield

mower with a high-pressure wash

gun.

Water and dirt

could be blasted

past

the seals

in

the

bearings causing

premature

bearing

failures and rusted

pivot points.

Never wash

your

Greenfield

mower

immediately after use. The

quenching

conkaction effect from hosing the machine

while at operating

temperature could also draw

water and dirt into

the bearings and cause

premature

bearing

failures.

The

best way to clean

your

Greenfield

is to

use

an air hose to

blow

loose

grass,

etc from around

pulley's,

belts

and the

top of the cutter deck. Wash

the exterior with

a

sponge

and

bucket, then rinse off with

a

hose and

wipe

it

down

the

same way as

you

would

your

car.

For maximum

machine

life, do not

spray

water

directly on the

pulley's

and bearings.

Reoil all

pivgts

after washing.

Allow

your

Greenfield

to cool after use

then clean off all

grass

and

other debris before storing. Sticks,

stones

or an

accumulation of

grass

and other debris will damage

belts and fracture pulleys

if they

go

between

the

pulley

and

belt.

When operating

in these conditions the cutter

deck may require more

frequent cleaning.

Chassis

Lubrication

Your

Greenfield

mower has

3

greasing points. A

grease

nipple

is fitted to

each

king

pin

housing

in

the

front

axle beam,

the third

grease

nipple

is fitted to the steering idler which

is located

in

the centre of the machine close behind the

front

axle beam and accessible from under

the

chassis.

Grease these locations

every 6 months or 50 operating hours with a

quality

No. 2 lithium base

grease

or equivalent.

It is recommended

your grease

gun

be fitted with a flexible hose

for

easier

access. All other exposed

pivot

joints,

lever

points

and

slides are to be

lubricated

with

engine

oil.

Belts

"V"

belts on Greenfield mowers are self-adjusting

although the

cutter belt

may

occasionally require an extra manual

adjustment

within

its

working

life

(see page

l2). Inspect the "V"

belts regularly and replace if

damaged.

Part numbers

for "V"

belts are:

Drive

V belt - GT

2354

Cutter V belt -

GT 2365

Important

-

Fof long

service

life, use only Genuine Greenfield branded V belts, refuse

substitutes.

Non

genuine

V belts

may render

the clutch

ineffective, even dangerous.

Cutter

Blades

Check condition of blades, blade bolts

and blade holder.

Replace

if damaged

or worn.

Damaged

or worn blades

and bolts are major

hazards.

Always

replace

damaged or worn blades

and bolts in sets to

preserve

balance.

Use

only Genuine Greenfield branded

replacement

parts.

Use of

inferior

non

genuine

replacement

parts

on

your

Greenfield

mower could result in costly

damage or even

personal

injury. The

part

number

for

blade and bolt set is:

Cutter Blade and

Bolt

Set

-

GT

2139

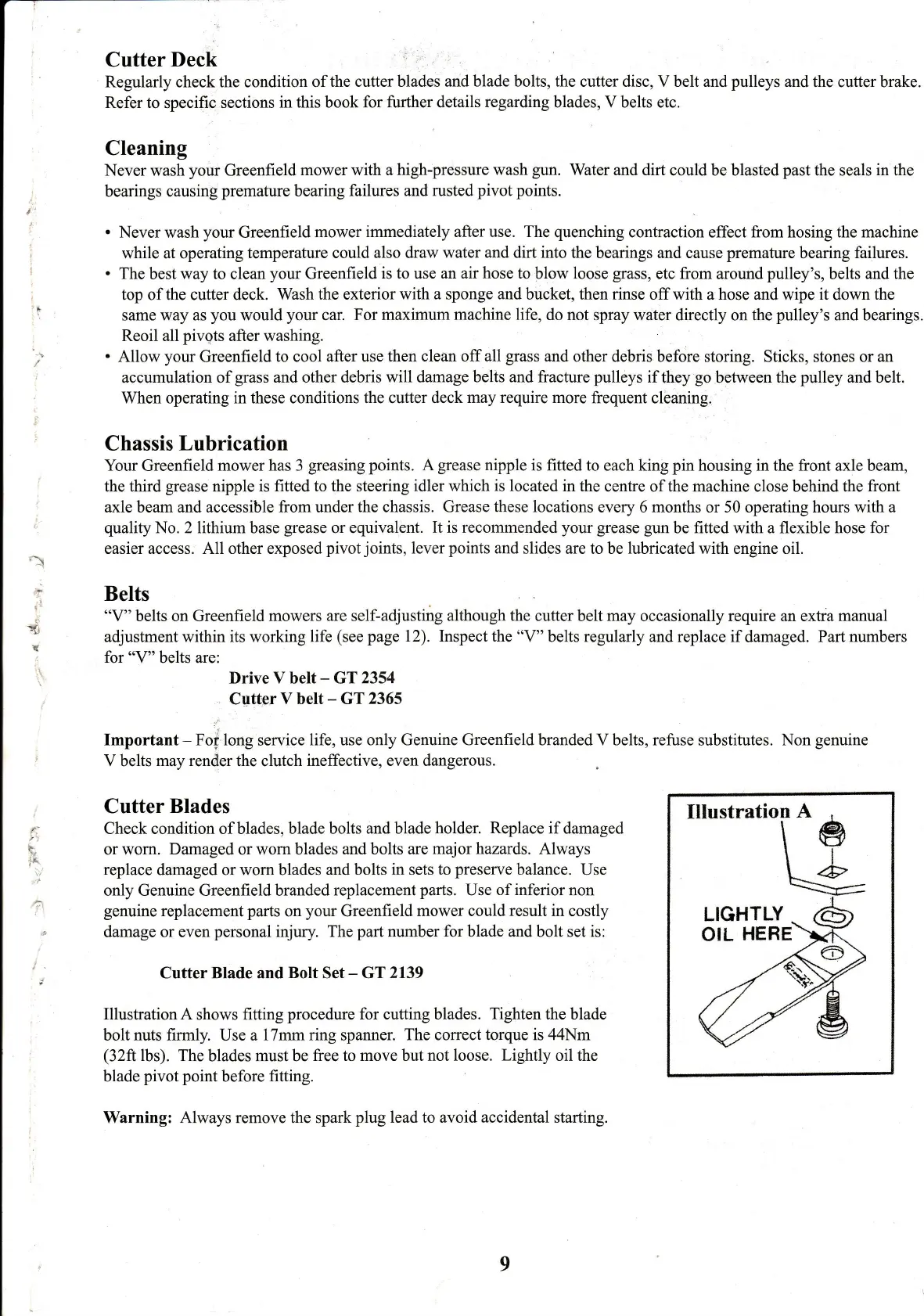

Illustration A

shows fitting

procedure

for cutting blades.

Tighten

the blade

bolt nuts firmly. Use a 17mm

ring

spanner.

The correct

torque

is 44Nm

(32ft

lbs). The

blades must be

free to move but not loose.

Lightly

oil the

blade

pivot point

before

fitting.

Warning:

Always

remove the spark

plug

lead to avoid accidental starting.

Illustratio

LIGHTLY

OIL

HERE

9

Loading...

Loading...