767 Hydraulic Hand Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

5

Ball Seat Repair

Reseating:

Minor seat imperfections may be corrected by reseat-

ing. Use a soft brass rod and hammer to tap the ball

against its seat.

Wear safety glasses when striking the

brass rod.

Reassembly is done in reverse sequence of disassembly.

Use repair kit 50034349 to replace all O-ring seals, balls

and springs.

Before installing O-rings, lightly coat O-ring seals and

bores of the cylinder with clean hydraulic oil.

Coat the discharge check spring (5) with a petroleum gel

before installation.

Fill unit with clean oil and purge air per instructions under

the Filling the Pump with Oil section of this manual.

Reassembly

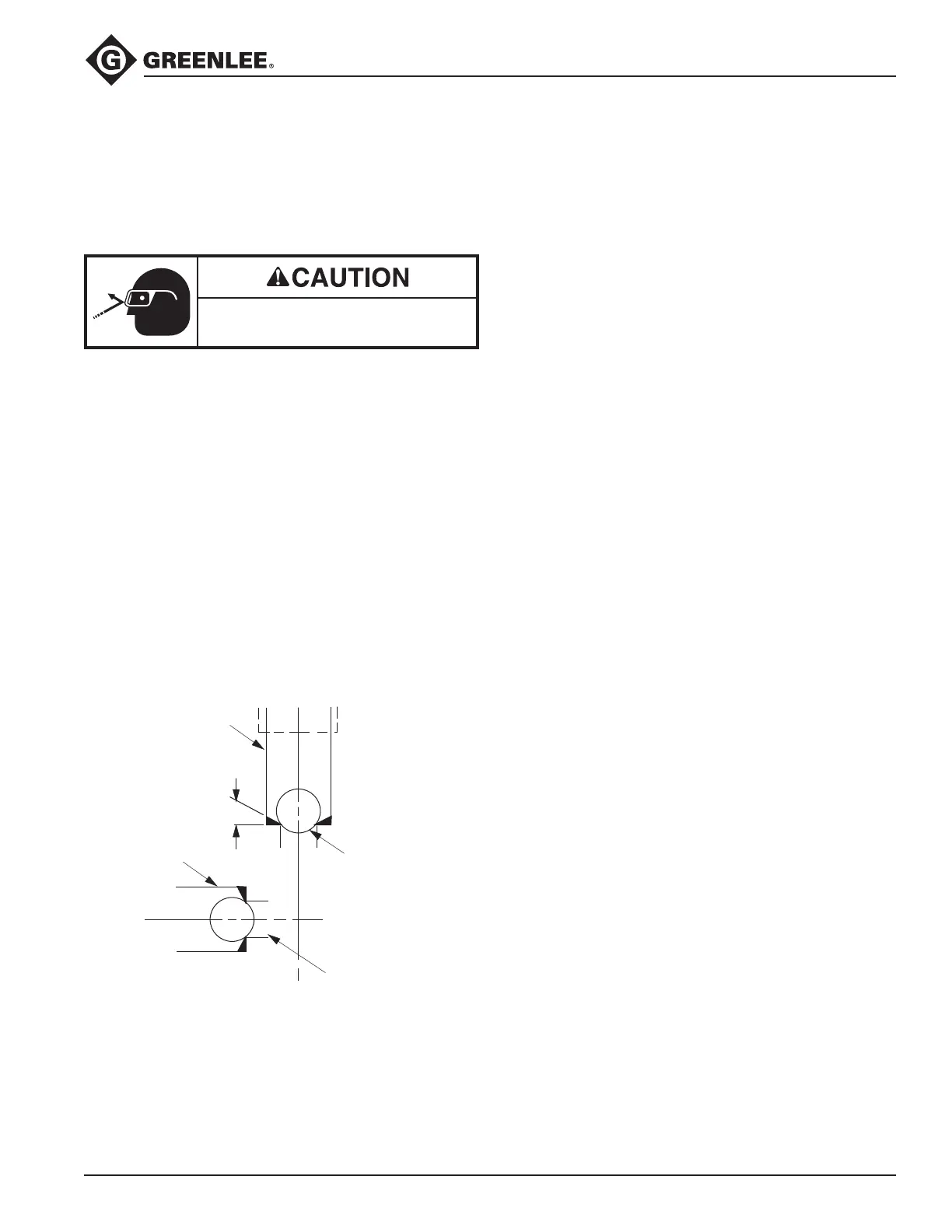

Re-drilling:

Badly worn or damaged seats may be reworked by

re-drilling and then re-seating.

The pump block is manufactured with seats of 118˚,

the standard drill point angle; use standard drills for

re-drilling.

• To re-drill the 3/16" ball seats (10):

Use an “F” drill and a 7/32" diameter reamer

• To re-drill the 1/4" ball seat (11):

Use a “Q” drill and a 13/64" diameter reamer

When drilling; remove a minimum of material to obtain

maximum seat life. Reseat the balls before reassembly.

“Q” DRILL

STD. DRILL

ACCEPTABLE

13/64" REAM

7/32" REAM

DISCHARGE

CHECK

RELEASE

VALVE

STEM

“F” DRILL

Loading...

Loading...