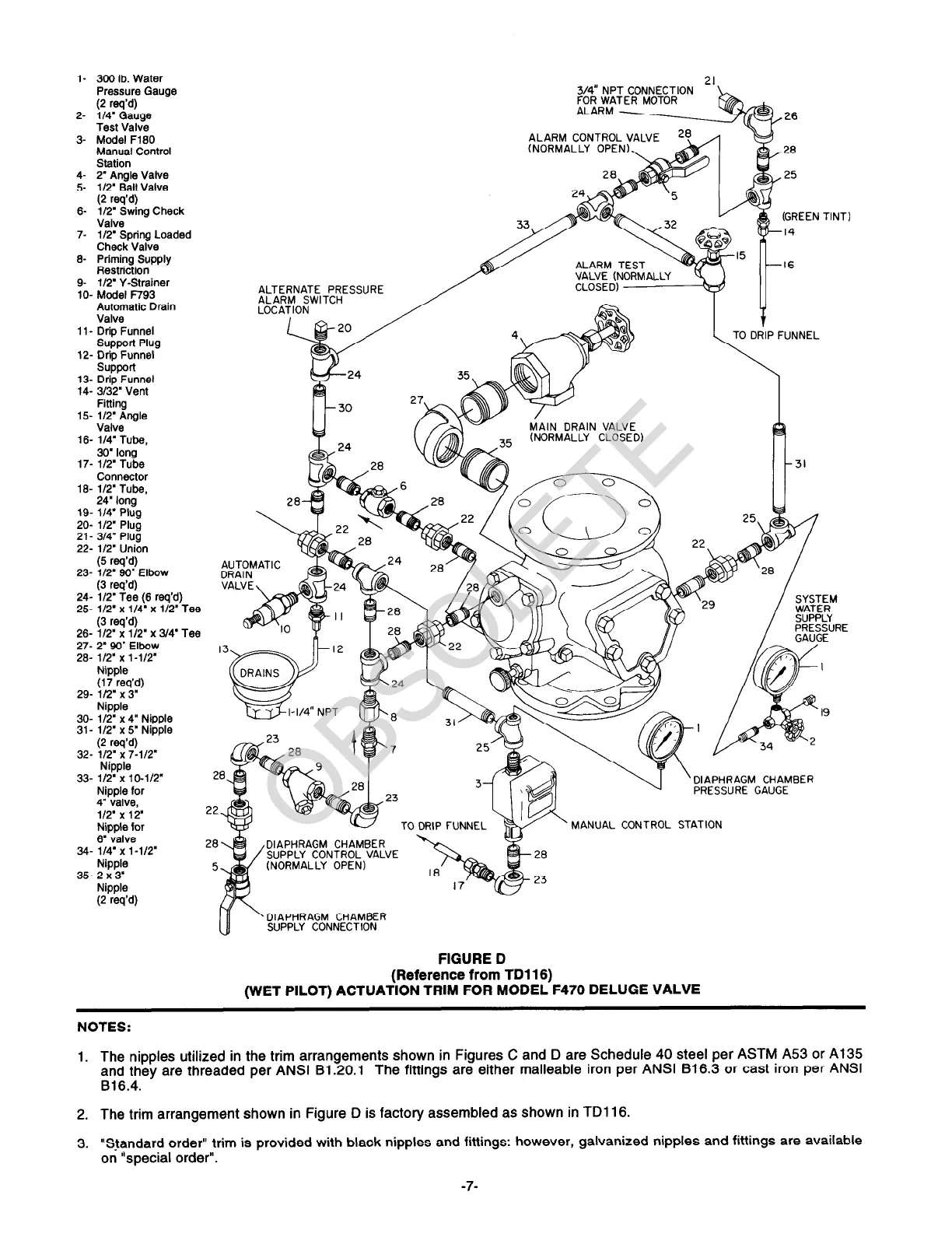

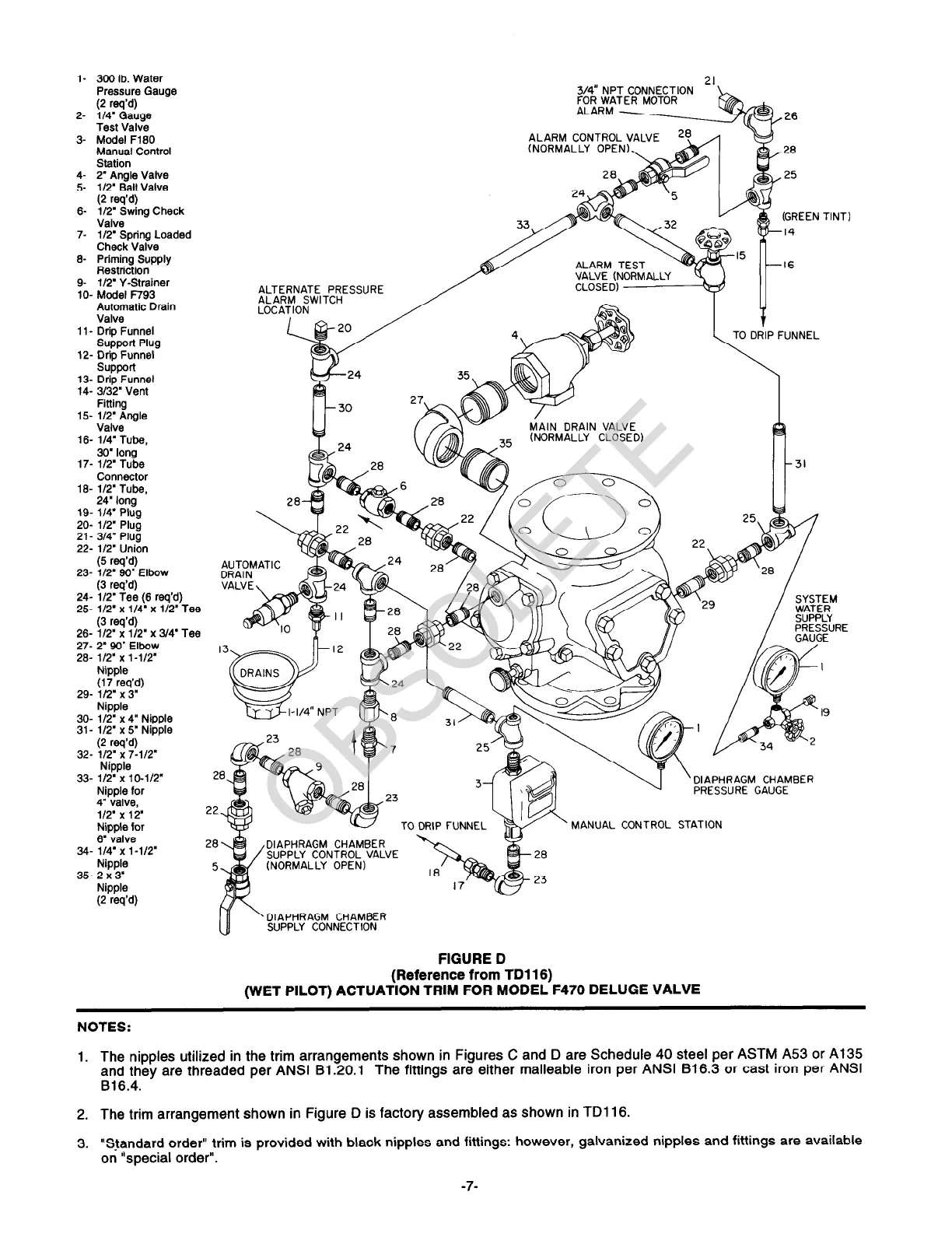

I- 300 lb. Water

Pressure Gauge

(2 req’d)

2- 114’ Gauge

Test Valve

3- Model Fli30

Manual Control

Station

4- 2’ Angle Vaive

5- l/2’ Ball Valve

(2 req’d)

6- l/2’ Swing Check

Valve

7- l/2’ Spring Loaded

Check Valve

6 Priming Supply

Restriction

9- I/2’ Y-Strainer

lo- Model F793

Automatic Drain

Valve

II- Drip Funnel

supporl Plug

12- Drip Funnel

Support

13- Drip Funnel

14- 3132’ Vent

Fitting

15- I/2’ Angle

Valve

16- I/4’ Tube,

30’ long

17- ll2’Tube

Connector

19 l/2’ Tube,

24’ long

19- l/4’ Plug

20- l/2’ Plug

21- 314” Plug

22- l/2’ Union

(5 w’d)

23- l/2’ 90’ Elbow

(3 req’d)

24- l/2’ Tee (6 req’d)

25- l/2’ x l/4’ x I/2” Tee

(3 req’d)

26- I/2’ x I/2’ x 3l4’ Tee

27- 2’ 90’ Elbow

29 l/2’ x1-112”

Nipple

(17 req’d)

29- l/2’ x 3’

Nipple

30- l/2” x 4” Nipple

31- I/2” x 5’ Nipple

(2 req’d)

32- l/2’ x7-112

Nipple

33- II2 x 10-l/2”

Nipple for

4” valve,

l/2’ x 12’

Nipple for

6’ valve

34- l/4’ x 1 -l/2

Nipple

35- 2 x 3

Nipple

(2 req’d)

13

21

‘CTION \

26

ALARM CONTROL VALVE *

(NORMALLY OPEN)

26

25

ALARM TEST 16

LLY CLOSED)

‘DIAPHRAGM CHAMBER

PRESSURE GAUGE

TO DRIP FUNNE

MANUAL CONTROL STATION

TO DRIP FUNNEL

DIAPHRAGM CHAMBER

SUPPLY CONTROL VALVE

(NORMALLY OPEN)

26

23

ul

‘DIAPHRAGM CHAMBER

SUPPLY CONNECTION

FIGURE D

(Reference from TD116)

(WET PILOT) ACTUATION TRIM FOR MODEL F470 DELUGE VALVE

NOTES:

1. The nipples utilized in the trim arrangements shown in Figures C and D are Schedule 40 steel per ASTM A53 or Al35

and they are threaded per ANSI B1.20.1

The fittings are either malleable iron per ANSI 816.3 or cast iron per ANSI

816.4.

2. The trim arrangement shown in Figure D is factory assembled as shown in TD116.

3. “Standard order” trim is provided with black nipples and fittings: however, galvanized nipples and fittings are available

on “special order”.

-7-

Loading...

Loading...