WWW.GFWORLDWIDE.COM | +1 (208) 664-9291

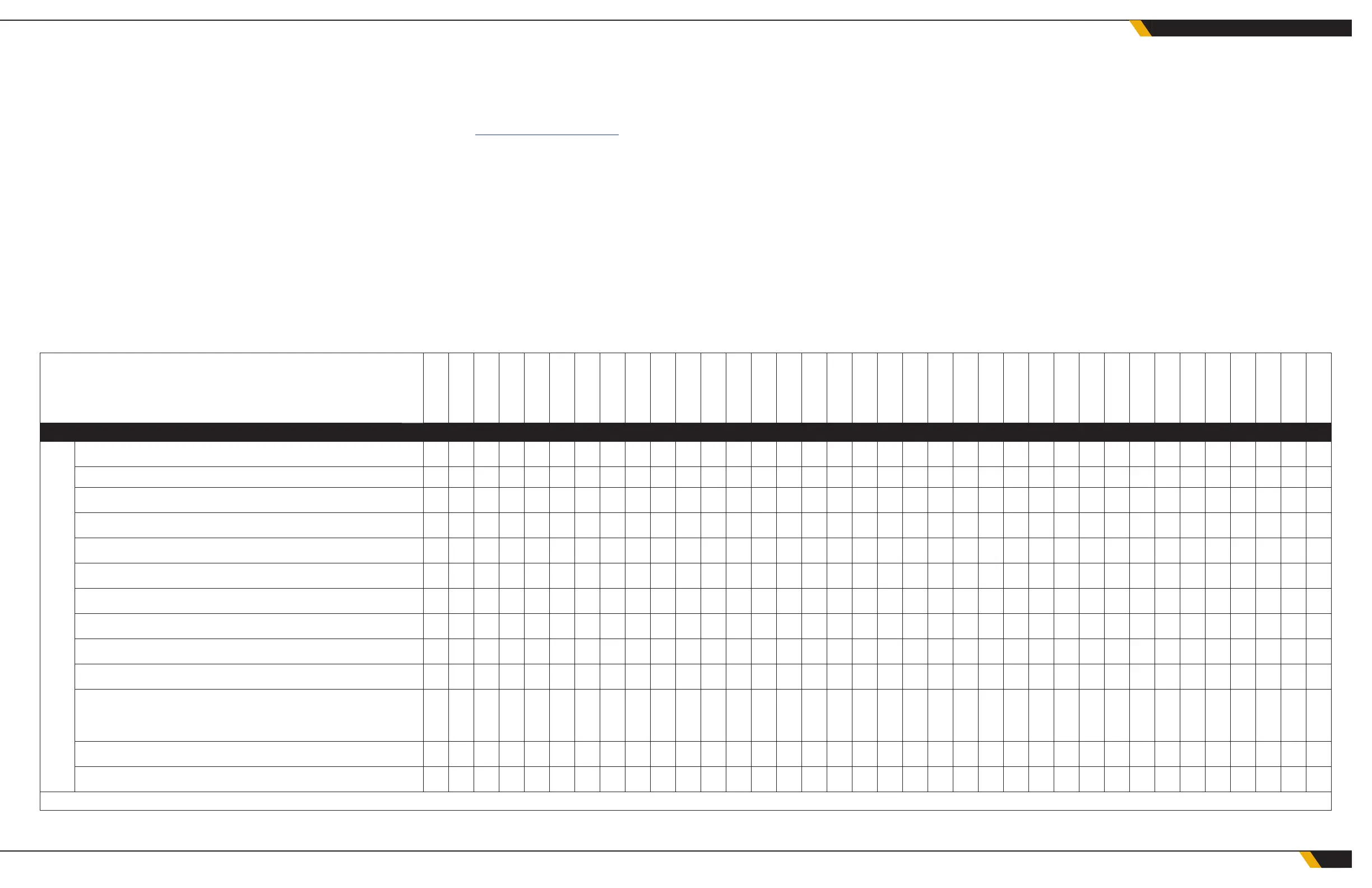

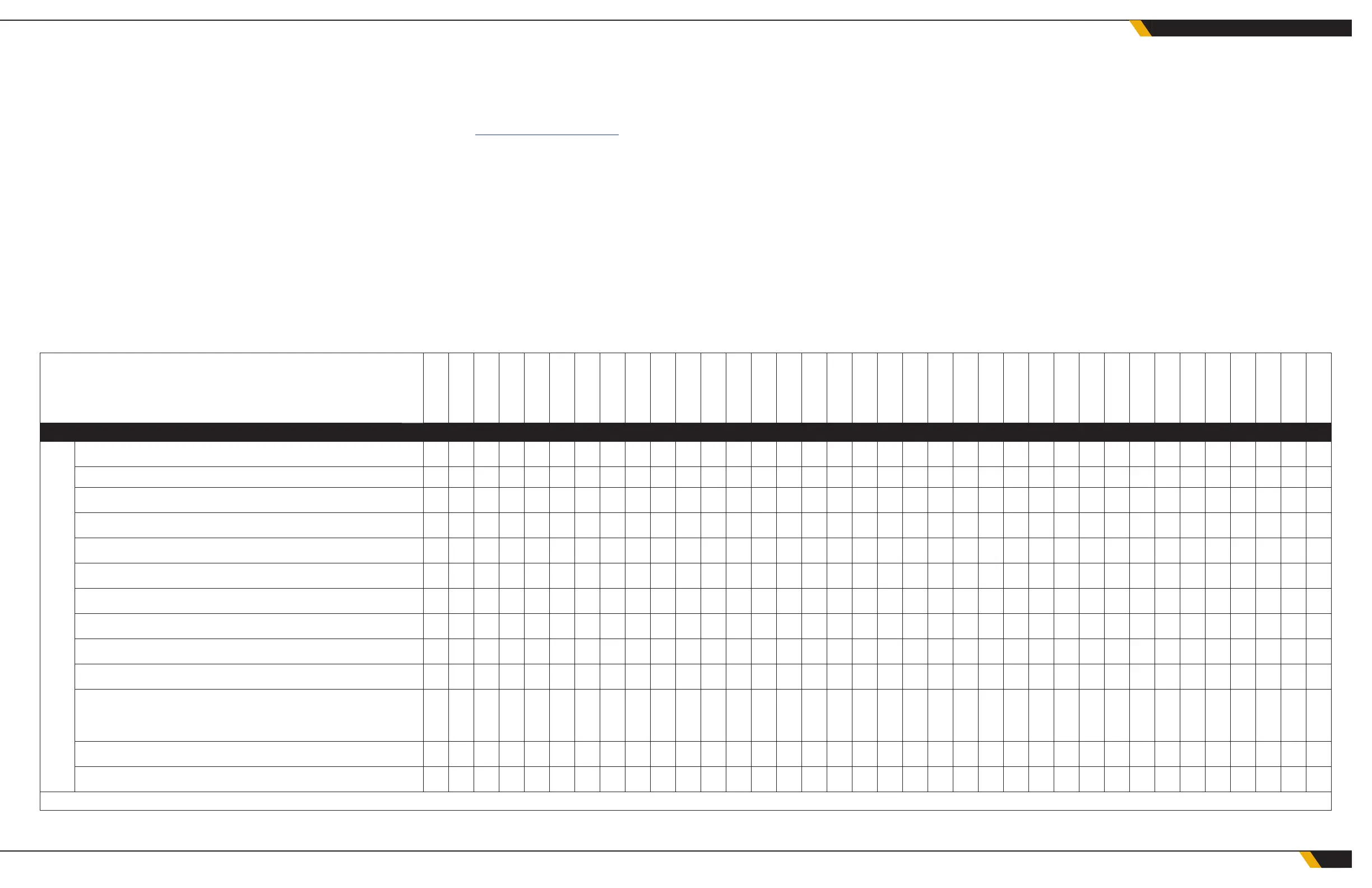

MAINTENANCE LOG

DATE ▼

DAILY MAINTENANCE SCHEDULE

DAILY

VISUALLY INSPECT

• HYDRAULIC FLUID LEVEL

• BODY MOUNTS

• REAR BODY PINS

• TANK MOUNTS

• PUMP MOUNTING BOLTS

• CHECK HOSES AND FITTINGS FOR LEAKS

• HOSES AND WIRING HARNESSES ARE SECURED

• FLUID LEVELS FOR AUX HEATER FUEL AND EXPANSION TANK

VERIFY HYDRAULIC CONTROL VALVES OPERATE PROPERLY

VERIFY SAFETY EQUIPMENT IS PRESENT AND FUNCTIONAL

INCLUDING EMERGENCY STOP SWITCHES, WHEEL CHOCKS AND

FIRE EXTINGUISHERS

VERIFY PROPER OPERATION OF ALL VALVES

VERIFY PROPER OPERATION OF THE AUXILIARY HEATING SYSTEM

*NOTE: FREQUENCY MAY VARY DEPENDING ON NEED. IT IS THE USER'S RESPONSIBILITY TO ESTABLISH APPROPRIATE SERVICE INTERVALS.

6.1 OVERVIEW

Maintaining your equipment will help prevent breakdowns and greatly

extend the service life of your Ground Force equipment. It is a fairly simple

process to maintain uid levels, change uids and lters when scheduled,

and monitor and tighten bolts or ttings that have worked loose.

6.2 MAINTENANCE SCHEDULES

Maintenance schedules are provided, including sample maintenance logs.

This will help with scheduling and tracking of maintenance.

6.3 VENDOR-SUPPLIED COMPONENTS

See the manufacturer's manual for maintenance, safety and operation infor-

mation for all non-Ground Force components. To request manufacturer's

manuals, contact Ground Force Technical support to request by writing to

service@gfworldwide.com.

6.4 OIL COOLER

If leaks develop in the oil to water cooler, it is possible for the hydraulic oil

to mix with the water. Observe the main hydraulic tank for signs of water

ingress or loss of hydraulic uid.

Inspect the seal by draining water in a bucket and looking for oil in the water

when putting into service after winter storage.

The oil-to-water cooler must be winterized or the water will freeze and dam-

age the cooler. Drain the water out of the cooler when freezing conditions

are possible by opening the drain valve and purging all water from the

cooler. Compressed air may be used to force water out of the cooler and

into the pump volute.

After blowing the water out, close the drain valve but leave the supply and

shutoff valves open to avoid trapping residual moisture.

39

MAINTENANCE SCHEDULES

Loading...

Loading...