WWW.GFWORLDWIDE.COM | +1 (208) 664-9291

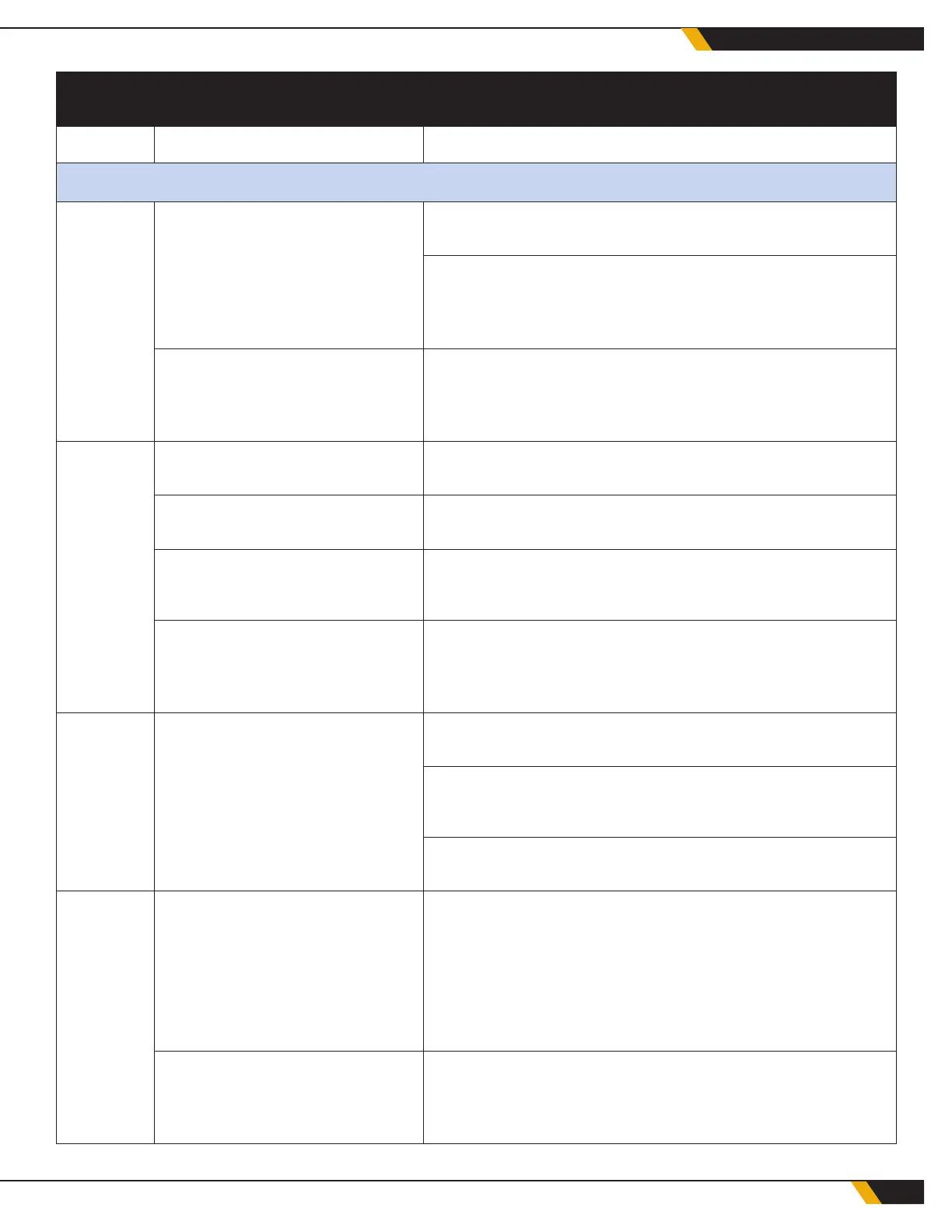

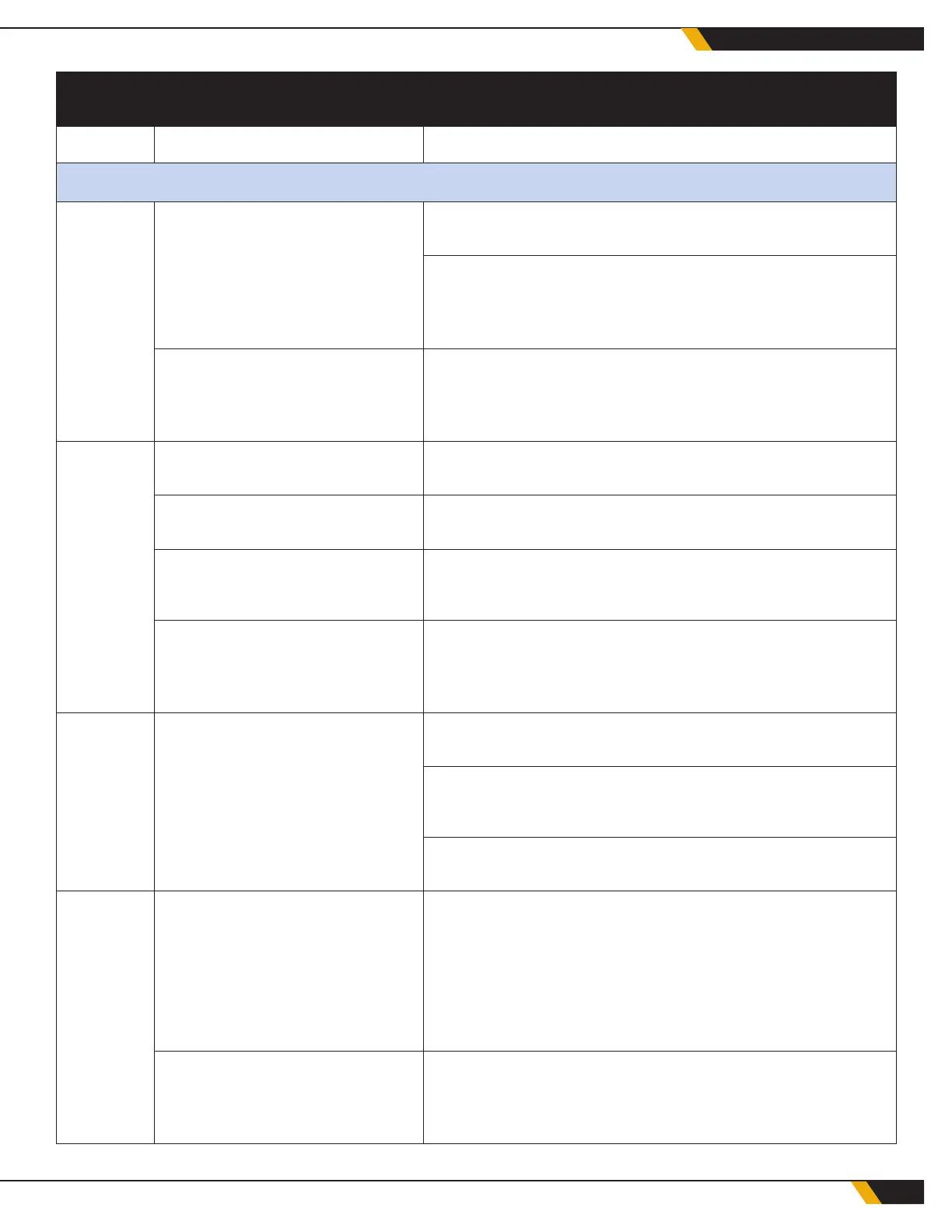

WATER TRUCK TROUBLESHOOTING

PROBLEM CAUSES SOLUTIONS

HYDRAULICS

The water pump/motor is

running too slow.

There is low hydraulic ow to the

water pump motor.

Check the hoist pump’s inline pressure lters. Check for a

dirty lter, and replace lter cartridge as needed.

Check the pressure and ow on the hoist pump. Excessive

contamination or metal particles in the lter may indicate

a worn hoist pump. Replace a bad or weak hoist pump as

required.

The water pump motor is weak. Check the case drain uid coming from the hydraulic mo-

tor. If ow is above 2 GPM, the hydraulic motor is failing.

The water pump motor could be bad even if the case drain

ow is less then 2 GPM.

The pump is hard to turn.

The bearings are worn out. Replace the shaft/bearing and install new seals. Grease

the bearings if equipped with serviceable bearings.

The packings on the water pump

are too tight.

Loosen the packing on water pump until you get about 1

drop per second.

The water pump has debris in

the pump keeping the impeller

from turning.

Clean the debris from inside the pump as needed. Check

the plumbing for rocks or other debris. Clean the sump

screen, piping and vortex breaker as needed.

Cold weather has caused

water in the pump to turn to

ice preventing the pump from

turning.

Thaw out the truck. Drain any water before parking the

truck, cover the ll chute so precipitation does not enter

the tank. If the truck needs to have water in it (for re pro-

tection for example), store the truck in a warm building.

The water pump is

hard to prime.

An air pocket is trapped in the

water pump, so the impeller is

not able to move the water.

Open the water cannon valve while lling the water tank.

Close it again before starting the water pump.

Add a small hose from the top port of the water pump.

Route the other end of the hose through a bulkhead back

into the water tank.

Position the truck on an incline facing uphill. Turn the wa-

ter pump on and off as needed to prime the water pump.

The hydraulic system is

overheating.

A hydraulic component(s)

is defective and generating

excessive heat.

Use an infrared temperature sensor to determine the heat

source. Example: The hydraulic oil temperature when exit-

ing the manifold assembly is about 10% higher than where

it enters manifold. Something within that manifold may

be the cause of the heat. Adjust or replace the cartridge

that is producing heat. Usually, the heat is from a pressure

relief valve needing adjustment or replacement.

A valve is stuck, a seal has gone

bad, or there is dirt or etched

hydraulic paths in the manifold.

Check the cartridges for wear, dirt and sticking valves, and

clean or replace as needed. Check the inside of the mani-

fold for hydraulic etching past seals causing uid paths in

the manifold. Replace as needed.

48

TROUBLESHOOTING

Loading...

Loading...