WWW.GFWORLDWIDE.COM | +1 (208) 664-9291

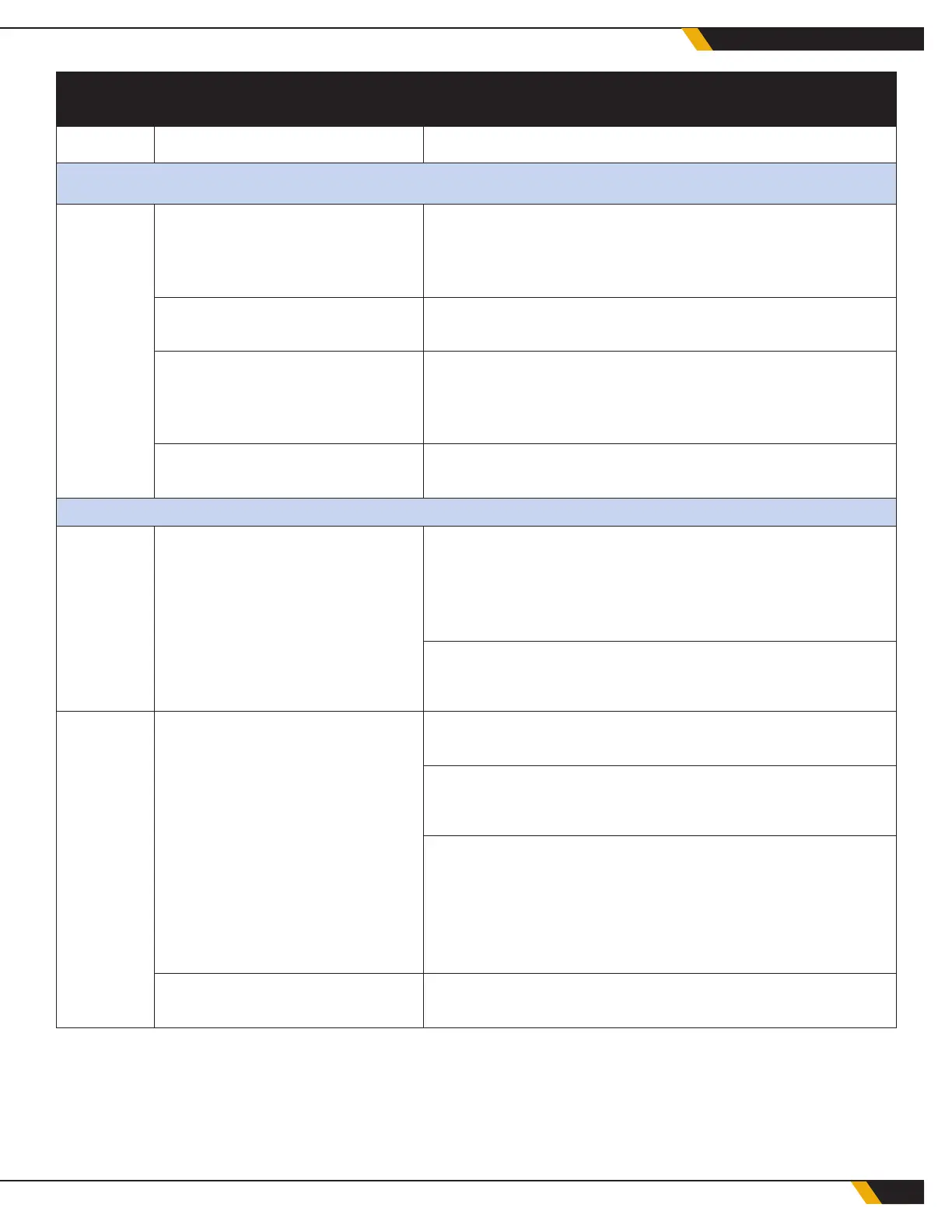

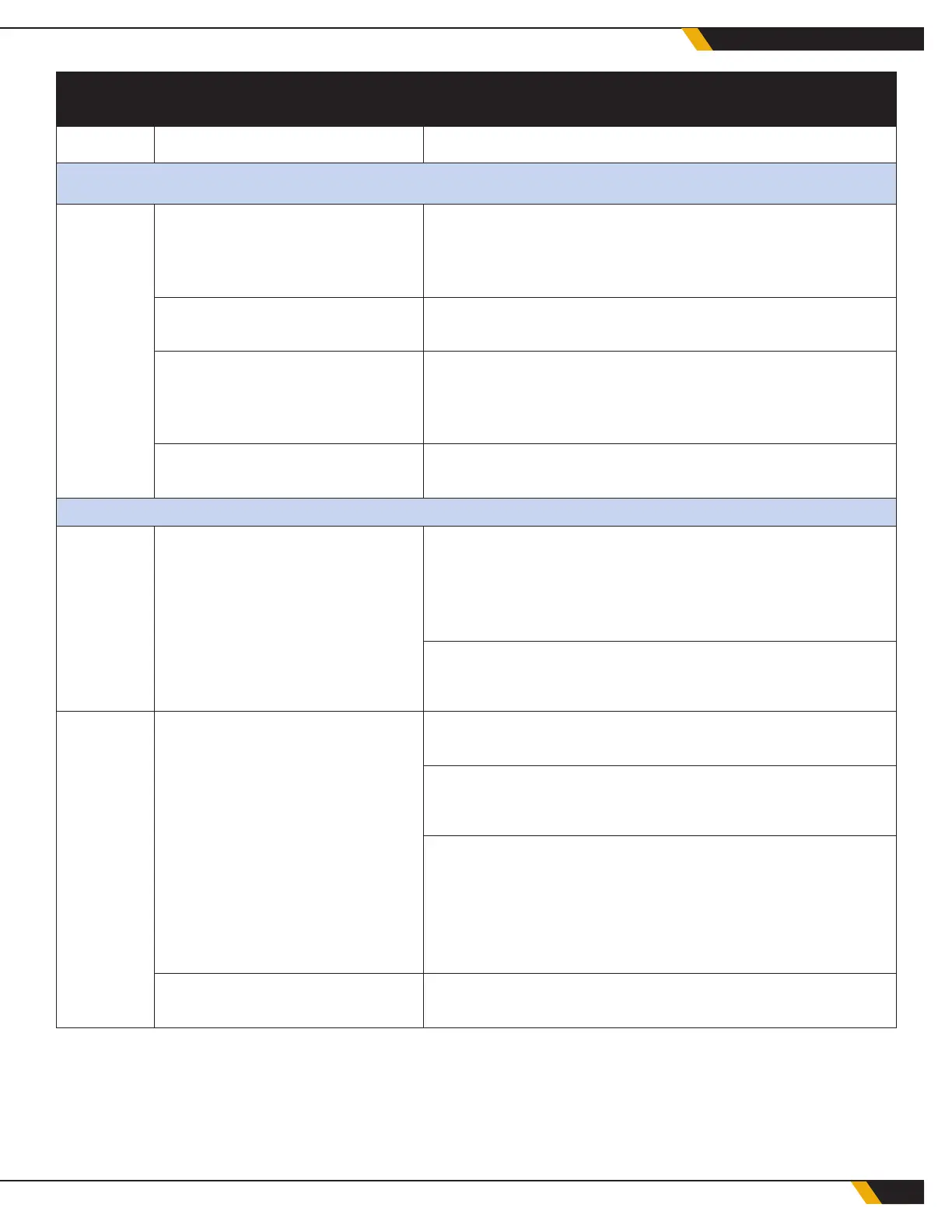

WATER TRUCK TROUBLESHOOTING

PROBLEM CAUSES SOLUTIONS

HYDRAULICS

The seal on the hydraulic motor

driving the water pump is leaking.

The case drain is not connected,

or is not correctly installed to

the hydraulic tank, causing back

pressure in the motor.

Verify the case drain is connected to the case drain port

on the back of the hydraulic motor. Verify the case drain

goes directly into the hydraulic tank as close as possible to

the tank if using a tee.

The case drain is installed going

into the return line of the motor.

Relocate the case drain, so it drains directly into the hy-

draulic tank.

The case drain hose is too

small.

The case drain from the motor uses # 8 hose. If multiple

hydraulic lines are used to return to the hydraulic tank, in-

crease the case drain hose to size # 12 and drain directly

into the hydraulic tank.

The hydraulic motor is defective. Replace the hydraulic motor.

WATER CANNON

The water cannon

buttery valve is not

closing all the way.

The buttery valve may have a

bent shaft from the valve being

opened when it was frozen shut.

Check the buttery valve for a bent shaft or arm and

replace as needed. To prevent this from happening in the

future, open the buttery valve with the water pump off

in cold weather to allow the water to drain from the water

cannon.

Install a recirculating line from the water cannon base

back into the tank to help keep the water moving in the

pipes, reducing the chance of freezing.

The buttery valve is not opening/

closing.

The solenoid or coil is

malfunctioning.

Check fuse, repair wiring and replace the fuse.

Check the wire connectors for a broken or loose connec-

tion. Give a light tug on each wire in the plug to verify it is

seated correctly. Repair as needed.

Check to see if the solenoid has magnetism by placing a

screwdriver across the top of the solenoid. If the solenoid

has magnetism but the solenoid valve is not activating,

the solenoid may be bad. If the solenoid has no magne-

tism, check the coil for resistance. If there is no resis-

tance, replace the bad coil.

A broken weld on the valve’s

pivoting arm.

Repair or replace as needed.

49

TROUBLESHOOTING

Loading...

Loading...