12

96-0041 Rev U

July 2010

6. MAINTENANCE

The linear guide trucks are lled with grease at the factory. Under infrequent

or light duty use the factory lube is sufcient for several months. It is important

that the axes are cycled to their full travel daily to coat the linear guides with

grease in order to protect the surfaces.

More severe use, such as cutting absorbent materials (such as wood), or

excessive coolant use (which washes the linear guides), will require weekly

greasing - Two strokes of the supplied grease gun is sufcient. Do not over

grease, as the excessive pressure of over-greasing or using a pneumatic or an

electrical grease gun is harmful to the seals. It is not necessary to see grease

squeezing out of the seals.

Grease type: General-purpose lithium

6

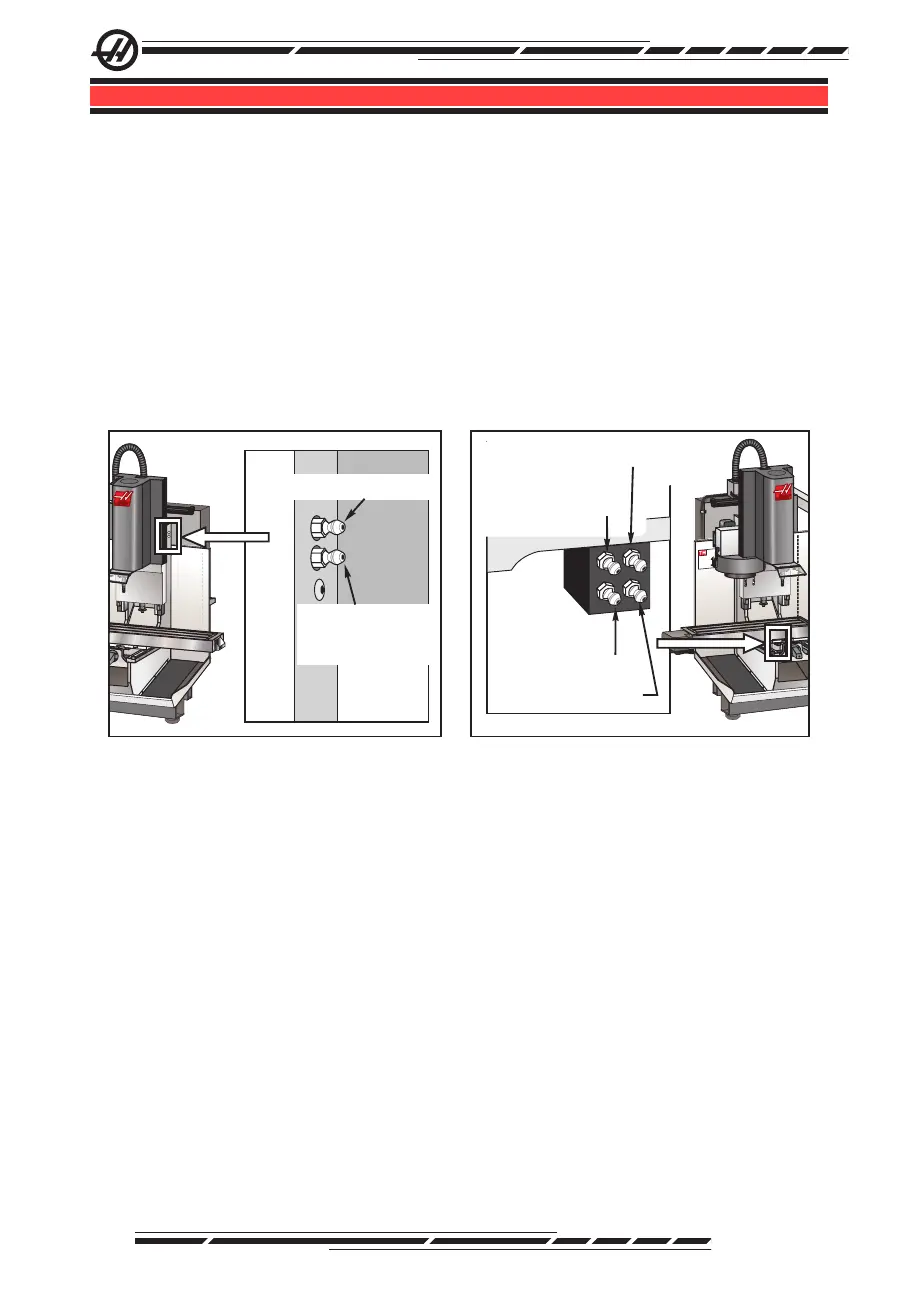

Z-Axis Ballnut

Z-Axis

Linear Guide

6

5

4

3

X-Axis Ballnut

Y-Axis Ballnut

Y-Axis Linear Guide

X-Axis Linear

Guide

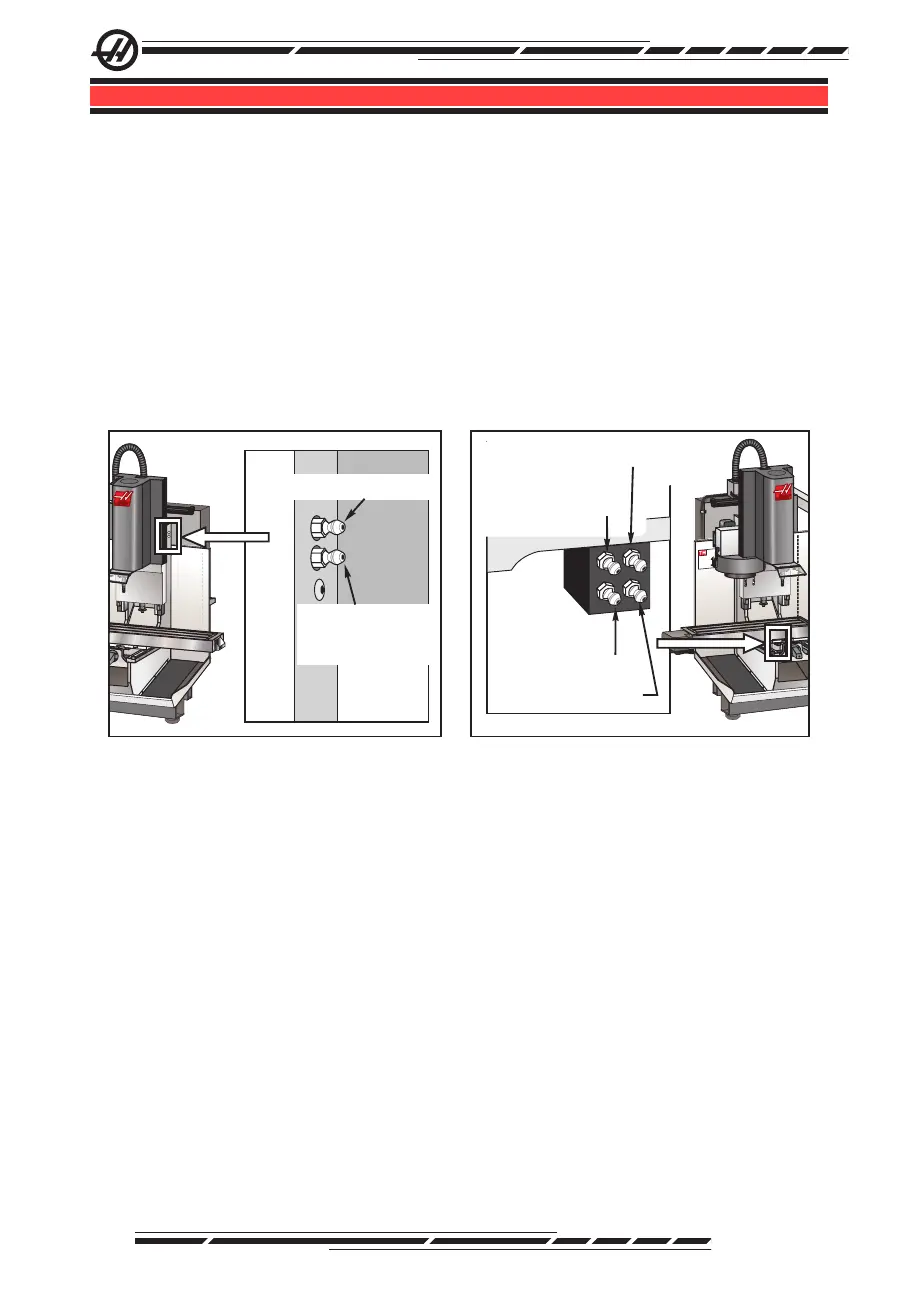

Grease tting locations. Mill pictured without enclosure for clarity

Also check the Maintenance chapter of the Operator’s manual for

additional maintenance issues.

Note that the Toolroom Mill does not have a gearbox or a TSC system; disre-

gard these maintenance sections.

Loading...

Loading...