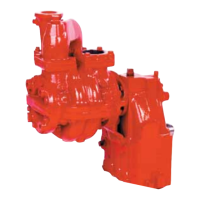

Operation and

Maintenance Manual for

Hale Booster Pumps

AP

CBP

2CBP

Hale Products cannot assume responsibility for product failure resulting from improper maintenance

or operation. Hale Products is responsible only to the limits stated in the product warranty. Product

specifications contained in this material are subject to change without notice.

HALE PRODUCTS, INC.

A Unit of IDEX Corporation

700 Spring Mill Avenue

Conshohocken, PA 19428

TEL: 610-825-6300

FAX: 610-825-6440

2002 HALE PRODUCTS, INC.,

MANUAL P/N 029-0020-53-0, REV A

ECO NO REV CHANGED FROM BY DATE APVD

02-0301 A RELEASED SAG 10/15/02 MAL

HALE PRODUCTS, INC

A Unit of IDEX Corporation

Conshohocken, PA 19428 USA

DRAWN BY: SAG ISSUE DATE:

CHECKED BY: PRW 10/15/02

COPYRIGHT ©

NOT TO BE REPRODUCED OR USED TO

MAKE OTHER DRAWINGS OR MACHINERY

9615