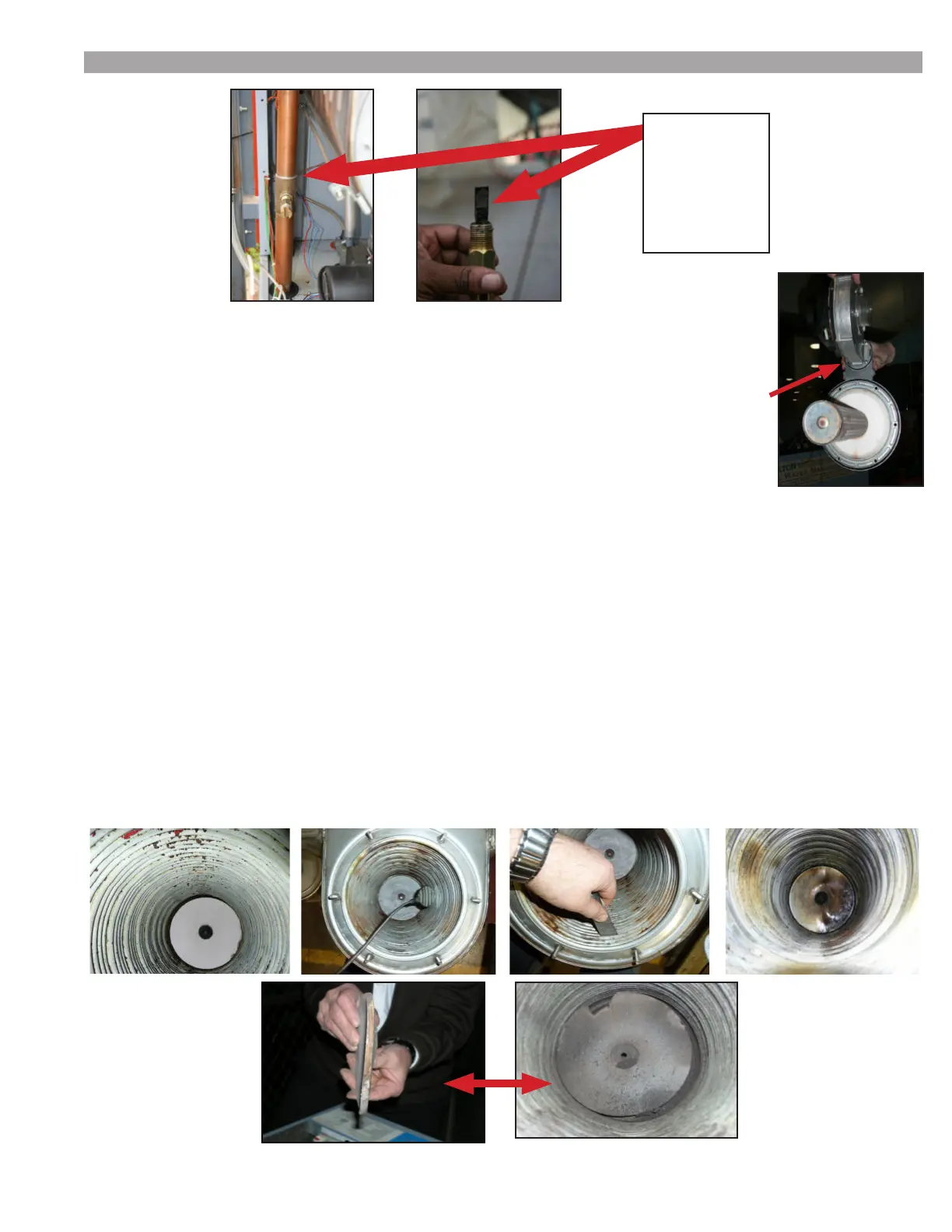

FLOW

SWITCH:

Check paddle for

fouling and free

movement by

spring!

34000 Autry Street, Livonia, MI 48150 • 800.968.5530 • Fax 734.419.0209 • www.hamiltonengineering.com • LIT91178 REV 5/2017

Page 3 of 9

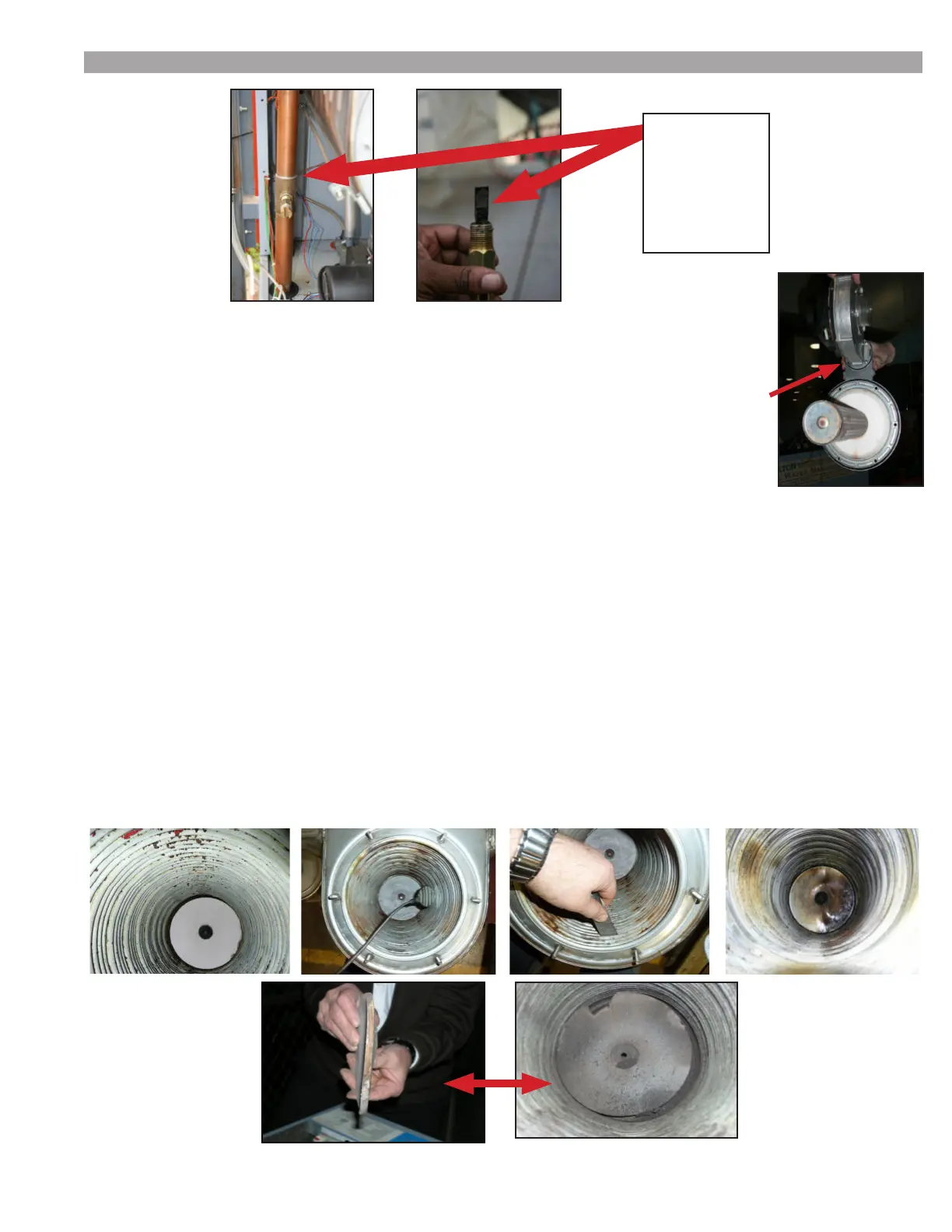

•Dismantletheburnerunit:removethe(6)6mmnuts(witha10mmsocket),theignition

cable, the power and speed control plugs, and the ground wire from the fan, and

remove the burner/fan unit from the heat exchanger and cabinet.

• After the burner door is removed, it should be thoroughly inspected

before being put back into service. There are two gaskets on the

burnerdoor;therstistheinnerropegasket,whichispermanentlyafxedtotheburner

door.Ifthisgasketiscompletelycompressed(havingnosealingability),thedoormust

bereplaced.Thesecondgasketisontheperimeterandismadeofrubber;thisgasket

is easily replaced, and comes as a standard part of a maintenance kit (and should always be replaced

during the annual maintenance procedure.

Note: Over-tightening the M6 nuts may cause the threaded

rods on the front of the heat exchanger to break! If excess resistance is encountered when installing

a M6 nut, discard that nut and use one of the spares shipped with the unit. The maximum torque for

assembling a burner door nut is 3.7 ft-lb or 44.4 in-lb. Use a torque wrench suitable for this torque

range to tighten the nuts.

•Removeandinspecttherearberboard.Ifanyresistanceisencounteredwiththeremovalofthescrew

securingtheberboardinplace,donotexertundoforce;breaktheberboardouttoprovideaccesstothe

screw. Apply penetrating oil to the screw, let it sit, then remove. See photos below for details. Replace only

aftercleaningprocedure.Useanewberboardifmoisturehasfouleditorifthereisanyphysicaldamage

preventingitfromprotectingtherearwall,suchascracksorwarping.Warpedberboardswillallowtheback

walltooverheat,thiscouldleadtoabreachofthebackwall.Thiswillalsocausealossofefciencyanda

rise in stack temperature.

Note: Failure to replace front and rear berboard when damaged may result

in irreparable damage to the appliance!

Complete burner,

door & fan assembly

removed for inspection

Both of

these

must be

replaced!

ANNUAL INSPECTION CONT.

Loading...

Loading...