41

PART 7. SERVICING

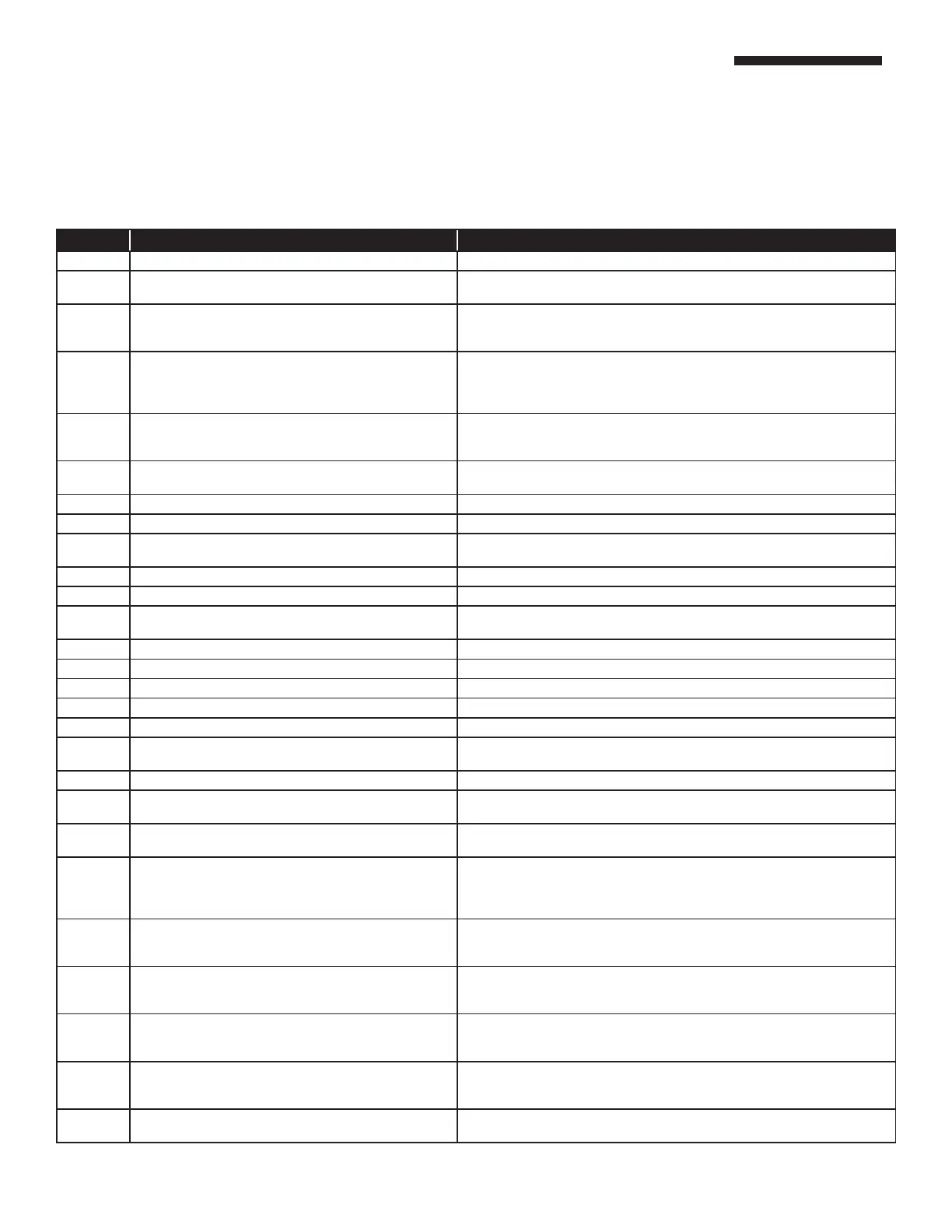

TABLE 73 BCB HARD LOCKOUT HLO CODES

Code Cause Recommended Action

A1/A2 Excessive pressure differential (∆P) on water side of heat exchanger Check for scaling or blockage on water side of heat exchanger, also check pump performance.

B03 Neutralizer/trap has little or no Condensate (water) Fill neutralizer (or trap if not a factory neutralizer) with water to avoid ue gases spilling into the

room through a dry trap.

B04 Pressure at ue/condensate sensor is too low Check ue gas vent connection or sensor connection located at condensate drain line. Also

check for a disconnected or open condensate drain line and last, look for a leak in the heat

exchanger outer casing (behind the insulation).

DW7 Temperature rise (∆T) through heat exchanger is too high Appliance has been through multiple tests and checks including operating at a reduced input to

avoid this shut down. The ∆P across the heat exchanger indicates reduced water ow. Check the

pump performance, check for partially closed valves and if all ok, perform a descaling operation

on the water side of the heat exchanger.

FL01 Flue gas temperature has exceeded the maximum safe level set in the

operating parameters

Flue gas temperature setting has been exceeded by a signicant amount even after operation at

a reduced ring rate. Check entire burner assembly, if ok, then a complete re side cleaning must

be initiated immediately.

FL05 Flue gas temperature too high Unit is burning at a reduced BTU input rate. The cause of the high ue gas should be investigated

and corrected ASAP—See FL01

FL09 Fire side of heat exchanger is severely fouled Remove burner and check condition of re side of tubes in the burner area.

G01 Gas pressure too low Find cause of low pressure and correct; piping or regulator sizing is the general culprit

G03 Gas pressure too high during a burn cycle Correct the cause of the high gas pressure - either adjust regulator or replace and repair as

required - maximum allowed by code is 14"w.c.

H15/H16 Water temperature limit set point exceeded Check set point(s), sensors, pumping etc. Correct cause of high water temperature

H24 Water Temperature Manual Reset High Limit set point exceeded Check set point(s), sensors, pumping etc. Correct cause of high water temperature

ID01 First INI process data missing Run the Z-INI; starting Initialization numbers must be tested and the saved for all connected

sensors in a number of conditions.

ID02 EMB EEPROM fault (2) Reset the fault, cycle power on and off, if the fault reappears, the EMB–EEPROM is corrupted.

ID03 No valid data on microcontroller Flash memory Reset the fault, cycle power on and off, if the fault reappears, the EMB–EEPROM is corrupted.

ID04 Internal fault (gv1) Reset the fault, cycle power on and off, if the fault reappears, the EMB–EEPROM is corrupted.

ID05 Internal fault (gv2) Reset the fault, cycle power on and off, if the fault reappears, the EMB–EEPROM is corrupted.

ID06 Internal fault (gv3) Reset the fault, cycle power on and off, if the fault reappears, the EMB–EEPROM is corrupted.

ID09 Fan speed error Cycle power off, check the four-wire fan connection; wires and each end at connectors. If all ok,

cycle power back on and if fan Speed error reappears, replace fan.

ID12 Flue thermostat open. Check for open ue temperature switch, if parameter S24=1

ID89 Fan is not running Either fan is not running (check wiring or replace), or factory programming has been altered

(consult factory).

ID96 Wrong EEPROM key connected Install proper EMB EEPROM, if it cannot be found, contact the factory for assistance - be sure to

have model and serial number of the appliance in question.

ID99 BDB Reset action nished There have been too many resets, a concerted effort must be made to nd the cause of the fault

and correct it. This is a timed action, and the unit cannot be reset until the time has elapsed.

Contact the factory with further questions. This fault will require both a power reset and then an

on-screen fault reset via the HISTORY tab.

IG2/IG3 Too many restarts or relights after no-ame. Appliance has been through multiple tests and checks including trying to ignite at different inputs

to avoid this shut down. Combustion related items must be checked, including air/gas ratio,

ignition cable and igniter. Check ow switch if installed.

IG4/IG5 Too many restarts or relights after no-ame. Appliance has been through multiple tests and checks including trying to ignite at different inputs

to avoid this shut down. Combustion related items must be checked, including air/gas ratio,

ignition cable and igniter. Check ow switch if installed.

IG19 Too many attempts for ignition Appliance has been through multiple tests and checks including trying to ignite at different inputs

to avoid this shut down. Combustion related items must be checked, including air/gas ratio,

ignition cable and igniter. Check ow switch if installed.

IG27 Too many attempts for ignition Appliance has been through multiple tests and checks including trying to ignite at different inputs

to avoid this shut down. Combustion related items must be checked, including air/gas ratio,

ignition cable and igniter. Check ow switch if installed.

P04 Low or no water ow Check for pump electrical issues i.e. no power to the pump, pump motor is seized, pump is

constantly powered and running.

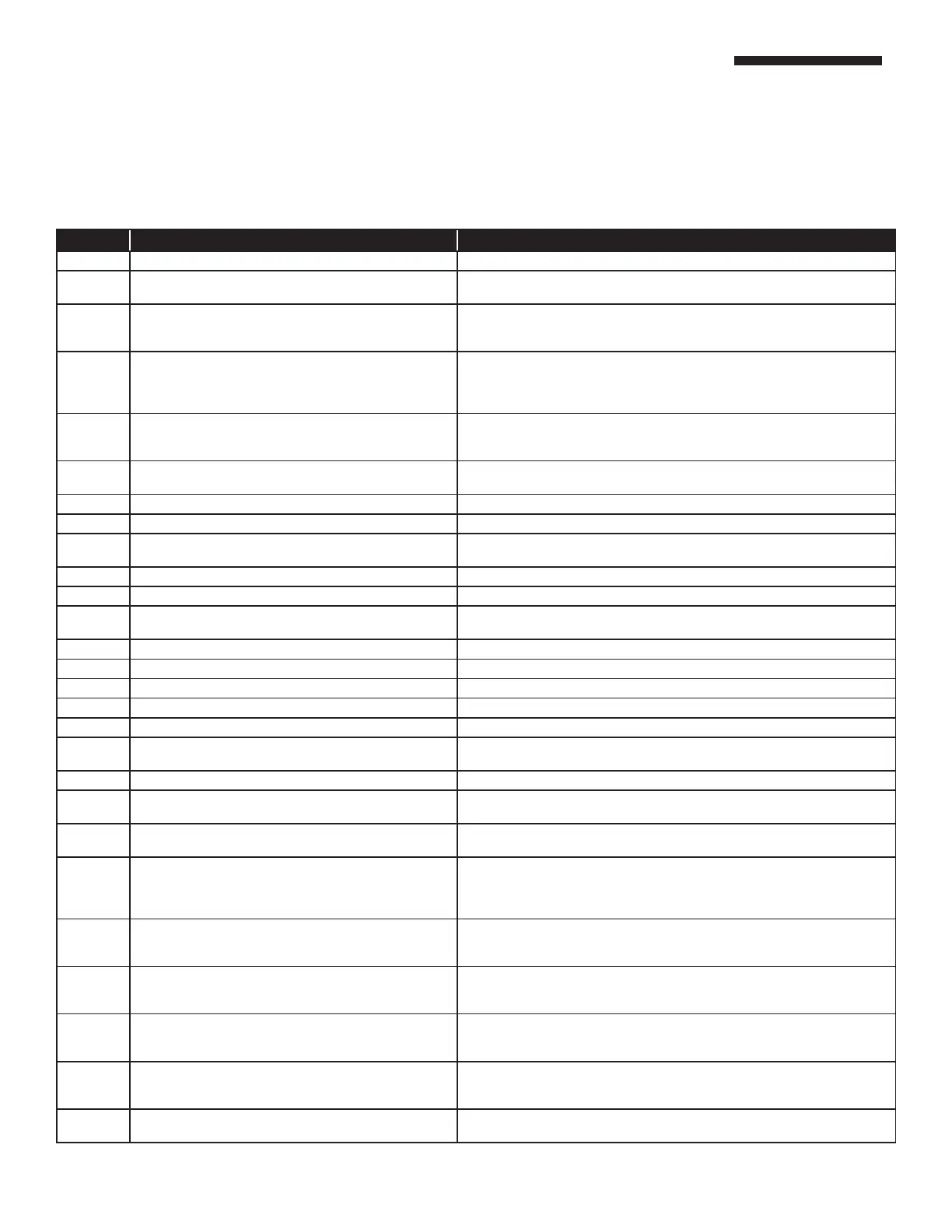

D. EVO HARD LOCKOUT CODES

Loading...

Loading...