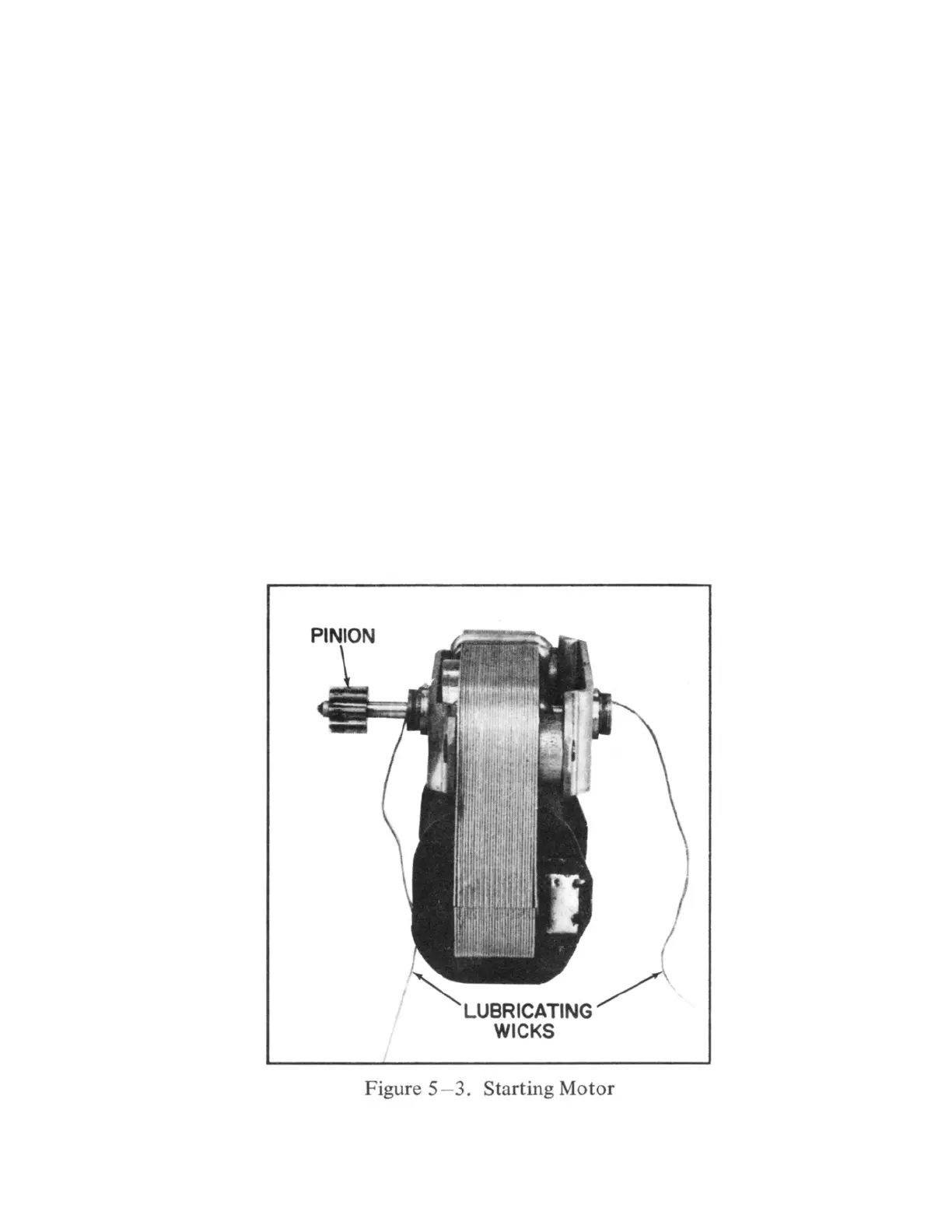

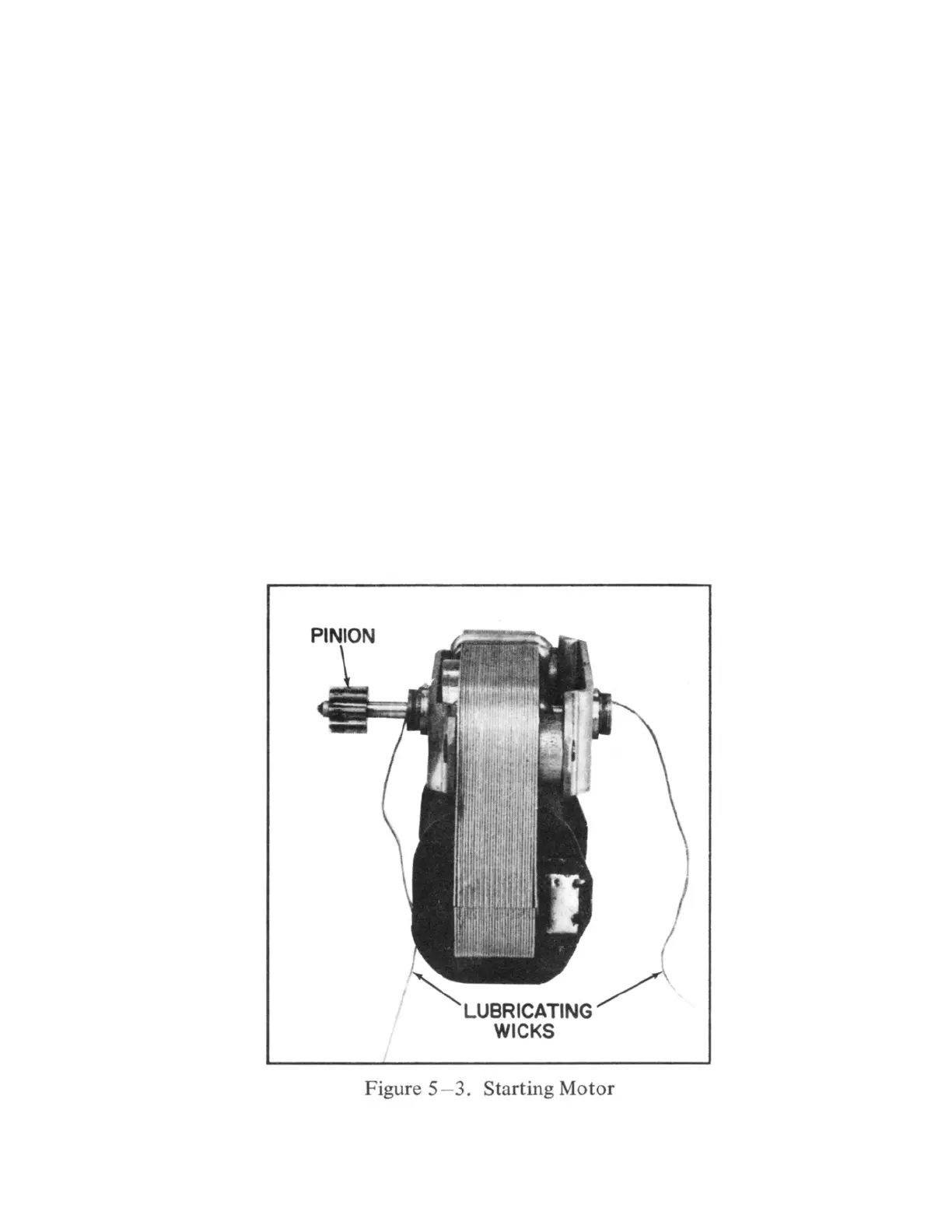

5-12. The start motor is a shaded-pole induction motor. The synchronous run motor

(used on 60 cycles) has a 2-pole field and 6-pole armature, and a synchronous speed

of 1,200 rpm (revolutions per minute). For 5O cycles, a 4-pole armature is used

which has a speed of 1,500 rpm. When the organ is placed into operation, the start

switch is first operated to apply power to the start motor. The rotor of the start

motor slides endwise and engages a pinion on its shaft which a gear on the generator

drive shaft. (See figure 5-3 below.) When the RUN switch is operated, while the

start switch is held in ON position, power is applied to the synchronous run motor

and a 250-0hm resistor (1,000 ohm for 234 volts) is connected in series with the

start motor, thus reducing the driving power of the start motor. Because of the

braking action and the loss of power of the start motor, the system slows down to,

and locks into, synchronous speed; the run motor then begins to carry the load. When

the START switch is released and springs back into position, the start motor

disengages from the drive shaft by action of a spring assembly, and stops.

5-13. The spring couplings of the motor shaft, the flexible couplings between the

sections of the drive shaft, and the tone wheel spring couplings are provided to

absorb the variations in motor speed. The synchronous motor operates with a series

of pulsations, one each half-cycle. If the tone wheels were coupled rigidly to the

motor, this irregularity would carry extra frequencies into each tone wheel. The

spring suspension system for supporting the main tone generator minimizes the

transmission of mechanical vibration between the console cabinet and the main

generator.

17

Loading...

Loading...