chisel or screwdriver through the radiator

grille in the wing. Using a suitable socket or

spanner remove the bolt and locking washer.

This bolt is sometimes very difficult to shift,

and hitting the free end of the spanner with a

heavy hammer is often the only way to start it.

Engage top gear and apply the handbrake

hard to prevent the engine from turning.

Alternatively, remove the starter motor

(Chapter 5A) and lock the flywheel with a

screwdriver or similar tool engaged with the

ring gear teeth.

7 Once the bolt has been slackened, set the

engine at TDC for No 1 piston as described in

Section 3.

8 Placing two large screwdrivers behind the

crankshaft pulley at 180º to each other,

carefully lever the pulley off. It is preferable to

use a proper pulley extractor if this is

available, but large screwdrivers or tyre levers

are quite suitable, providing care is taken not

to damage the pulley flange.

9 Remove the Woodruff key from the

crankshaft nose with a pair of pliers and store

it safely as it is a very small part and can easily

be mislaid.

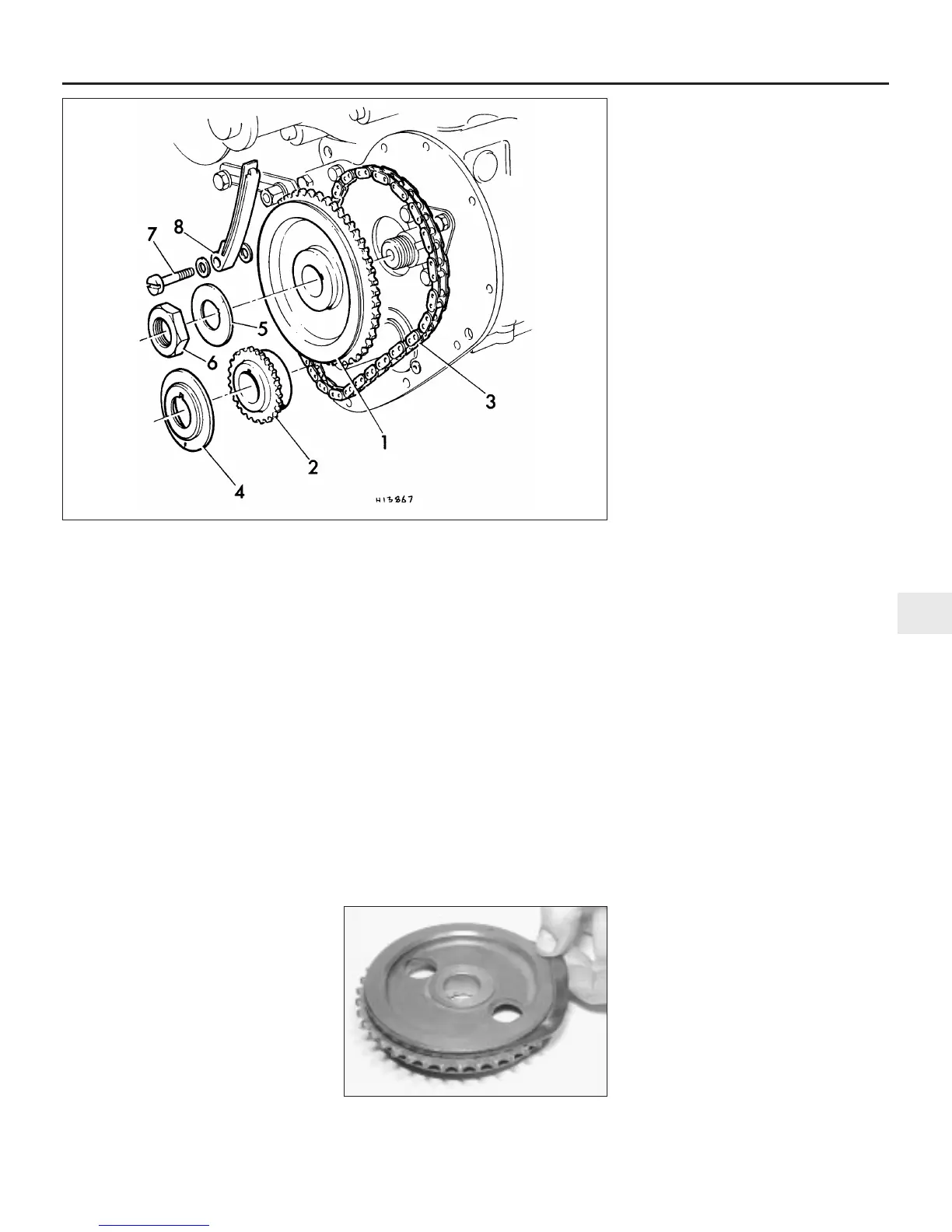

10 Unscrew the bolts holding the timing

cover to the block. Note: Four of the bolts are

larger than the others and each bolt makes

use of a large flat washer as well as a spring

washer.

11 Take off the timing cover and gasket. If

fitted, detach the engine breather hose from

the cover.

12 With the timing cover removed, slide off

the oil thrower. Note: The concave side faces

forward.

13 Bend back the locking tab on the washer

under the camshaft retaining nut and unscrew

the nut, noting how the locking washer

locating tag fits in the camshaft sprocket

keyway (see illustration).

14 To remove the camshaft and crankshaft

sprockets complete with chain, ease each

sprocket forward a little at a time, levering

behind each one in turn with two large

screwdrivers at 180º to each other. If the

sprockets are locked solid, it will be

necessary to use a suitable puller. With both

sprockets removed, extract the Woodruff

keys from the crankshaft and camshaft with a

pair of pliers and store them safely. Note that

there may be a number of very thin packing

washers behind the crankshaft sprocket; if so

carefully remove them.

15 On later models, unscrew the timing chain

tensioner retaining bolt and remove the bolt

and tensioner. Note that there is a washer on

each side of the tensioner arm.

Inspection

16 Thoroughly clean all the components with

paraffin or a suitable solvent and dry

thoroughly. Pay particular attention to the

timing cover and the mating face on the

engine front plate, ensuring that all traces of

old gasket are removed.

17 Examine the teeth on both the crankshaft

and camshaft sprockets for wear. Each tooth

forms an inverted “V” with the sprocket

periphery and, if worn, the side of each tooth

under tension will be slightly concave in shape

when compared with the other side of the

tooth. If any sign of wear is present the

sprockets must be renewed.

18 Examine the links of the chain for side

slackness and renew the chain if any

slackness is noticeable when compared with

a new chain. It is a sensible precaution to

renew the chain at about 60 000 miles, and at

a lesser mileage if the engine is dismantled for

a major overhaul. The actual rollers on a very

badly worn chain may be slightly grooved.

Cooper S type engines use duplex chains.

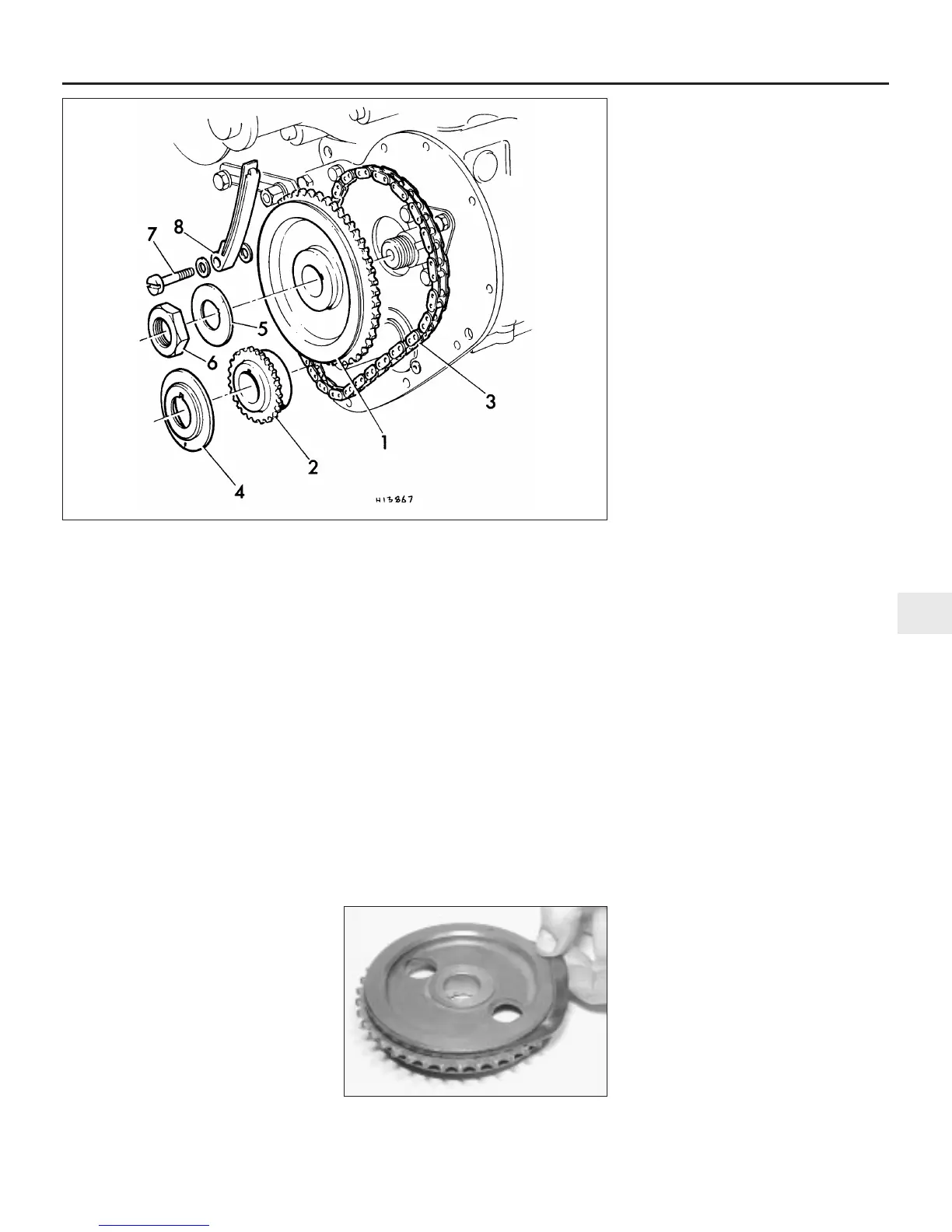

19 Also check the rubber tension rings in the

camshaft sprocket, where fitted. It is quite

likely that the rubber will have become hard

due to heat and oil contamination and it is

advisable to renew them as a matter of

course. The rings are simply prised out with a

screwdriver and new rings stretched over the

sprocket flanges and into the grooves (see

illustration). A spring-loaded rubber

tensioning pad may be fitted to the timing

cover on Cooper S type and later engines in

place of the tensioning rings. If the rubber pad

is grooved where it bears against the chain, it

should also be renewed.

20 It is advisable to renew the timing cover

oil seal at this stage. Drive out the old seal and

tap in the new one using the old seal to

spread the load. Ensure that the open side of

the seal faces inward, towards the chain.

Refitting

Note: Before reassembly begins check that

the original packing washers are in place on

the crankshaft nose. If new sprockets are

being fitted it may be necessary to fit

additional washers (see paragraph 25). These

washers ensure that the crankshaft sprocket

lines up correctly with the camshaft sprocket.

21 Refit the Woodruff keys in their respective

slots in the crankshaft and camshaft, and

ensure that they are fully seated. If their edges

are burred they must be cleaned with a fine

file.

22 Lay the two sprockets on a clean surface

so that the timing dots are adjacent to each

other. Slip the timing chain over them and pull

Engine in-car repair procedures 2A•5

2A

5.19 Fitting a new tensioning ring to the

camshaft

5.13 Timing sprocket and chain assembly - later type with tensioner arm

1 Camshaft sprocket

2 Crankshaft sprocket

3 Timing chain

4 Oil thrower

5 Lockwasher

6 Nut

7 Tensioner retaining

bolt

8 Tensioner

Loading...

Loading...