This can be checked by removing No 1 spark

plug and feeling the pressure being developed

in the cylinder as the piston rises, or by

removing the rocker cover and noting when the

valves of No 4 cylinder are rocking, ie the inlet

valve just opening and the exhaust valve just

closing. On manual transmission models, the

engine can be turned over quite easily by

engaging top gear and moving the car

forwards. This should only be done on level

ground; and make sure that the car cannot run

away! An alternative method, and the method

that should be used on automatic transmission

models, is to press the fan belt midway

between the water pump pulley and dynamo or

alternator pulley and then turn the fan blades.

Fine positioning of the torque converter can be

done by inserting a screwdriver through the

access hole and turning the ring gear.

6 Continue turning the engine, in the correct

direction of rotation, until No 1 piston is at

TDC on the compression stroke. Verify this by

checking that the timing marks are aligned.

The timing marks on the flywheel (or torque

converter), and the pointer on the housing,

can be viewed through the inspection

aperture using a small mirror. The 1/4 mark on

the flywheel or torque converter indicates

TDC and should be aligned with the pointer in

the housing. On later models with a timing

scale on the timing cover, the notch in the

crankshaft pulley should be aligned with the 0

pointer on the timing cover scale.

7 The distributor rotor arm should now be

pointing towards the No 1 spark plug HT lead

segment in the distributor cap indicating that

the crankshaft is correctly positioned with

number 1 cylinder at TDC on its compression

stroke. Temporarily place the cap in position

to verify this if necessary. If the rotor arm is

pointing at the No 4 HT lead segment in the

cap, rotate the crankshaft one full turn (360º)

until the TDC timing marks are realigned and

the rotor arm is pointing at the No 1 segment.

4 Valve clearances -

adjustment

2

1 The valve adjustments should be made with

the engine cold. The importance of correct

rocker arm/valve stem clearances cannot be

overstressed as they vitally affect the

performance of the engine. If the clearances

are set too wide, the efficiency of the engine is

reduced as the valves open later and close

earlier than was intended. If, on the other

hand the clearances are set too close there is

danger that the stems will expand upon

heating and not allow the valves to close

properly, which will cause burning of the valve

head and seat, and possible warping.

2 To gain access to the rocker arms, remove

the ignition shield (where fitted) from the front

of the engine then undo the two rocker cover

retaining bolts. Lift out the bolts along with the

ignition shield brackets and lift the rocker

cover and gasket away. Collect the rocker

cover retaining bolt dished washers from the

top of the two rubber seals.

3 It is important that the clearance is set when

the tappet of the valve being adjusted is on the

heel of the cam, (ie opposite the peak). Turn

the engine until valve No 8 (nearest the

flywheel end of the engine) is fully open. With

the engine in this position, valve No 1 will be

fully closed and ready to be checked. On

manual transmission models, the engine can

be turned over quite easily by engaging top

gear and moving the car forwards. This should

only be done on level ground; and make sure

that the car cannot run away! An alternative

method, and the method that should be used

on automatic transmission models, is to press

the fan belt midway between the water pump

pulley and dynamo or alternator pulley and

then turn the fan blades.

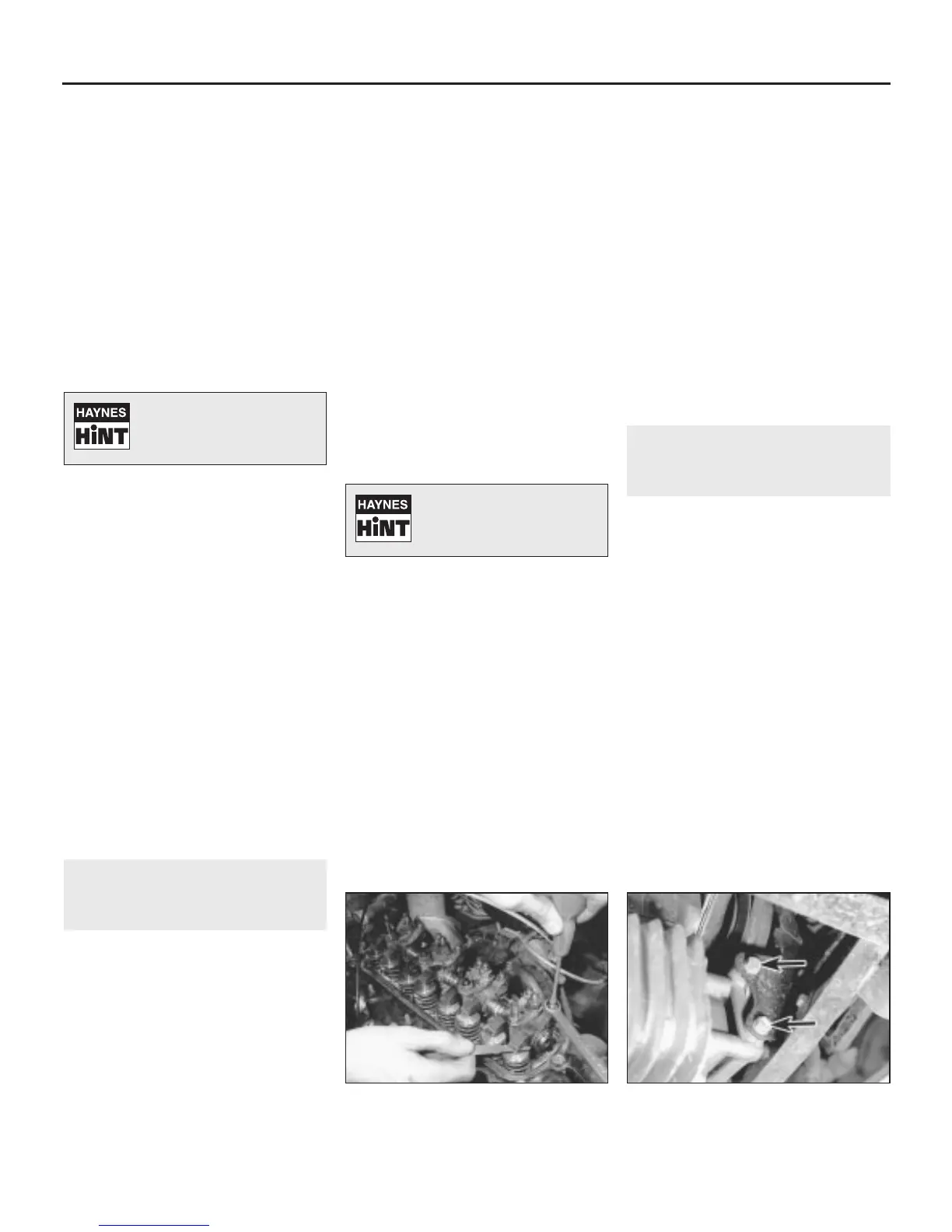

4 A feeler blade of the correct thickness

should now be inserted between the valve

stem and rocker arm. When the clearance is

correct the feeler blade should be a smooth

stiff sliding fit between the valve stem and

rocker arm. The correct valve clearances are

given in the Specifications at the start of this

Chapter.

5 If the feeler blade is a tight or loose fit then

the clearance must be adjusted. To do this,

loosen the locknut of the adjustment stud and

screw the adjuster stud in or out until the

feeler blade can be felt to drag slightly when

drawn from the gap (see illustration).

6 Hold the adjuster firmly in this position and

tighten the locknut. Recheck the gap on

completion to ensure that it has not altered

when locking the nut and stud.

7 Check each valve clearance in turn in the

following sequence (which also avoids turning

the crankshaft more than necessary). The

valves are numbered from the timing chain

end of the engine.

Valve fully open Check and adjust

Valve No 8 Valve No 1

Valve No 6 Valve No 3

Valve No 4 Valve No 5

Valve No 7 Valve No 2

Valve No 1 Valve No 8

Valve No 3 Valve No 6

Valve No 5 Valve No 4

Valve No 2 Valve No 7

8 When all the valves have been checked and

adjusted, refit the rocker cover using a new

gasket and secure with the retaining bolts.

Where applicable, remember to fit the ignition

shield brackets with the retaining bolts. Avoid

over-tightening the rocker cover bolts.

9 Refit the spark plugs, HT leads and ignition

shield.

5 Timing chain, tensioner and

sprockets - removal,

inspection and refitting

3

Removal

1 Disconnect the battery negative lead.

2 Refer to Chapter 1 and remove the fan belt.

3 Refer to Chapter 3 and remove the radiator.

4 Undo the bolts securing the fan to the water

pump spindle, and remove the fan.

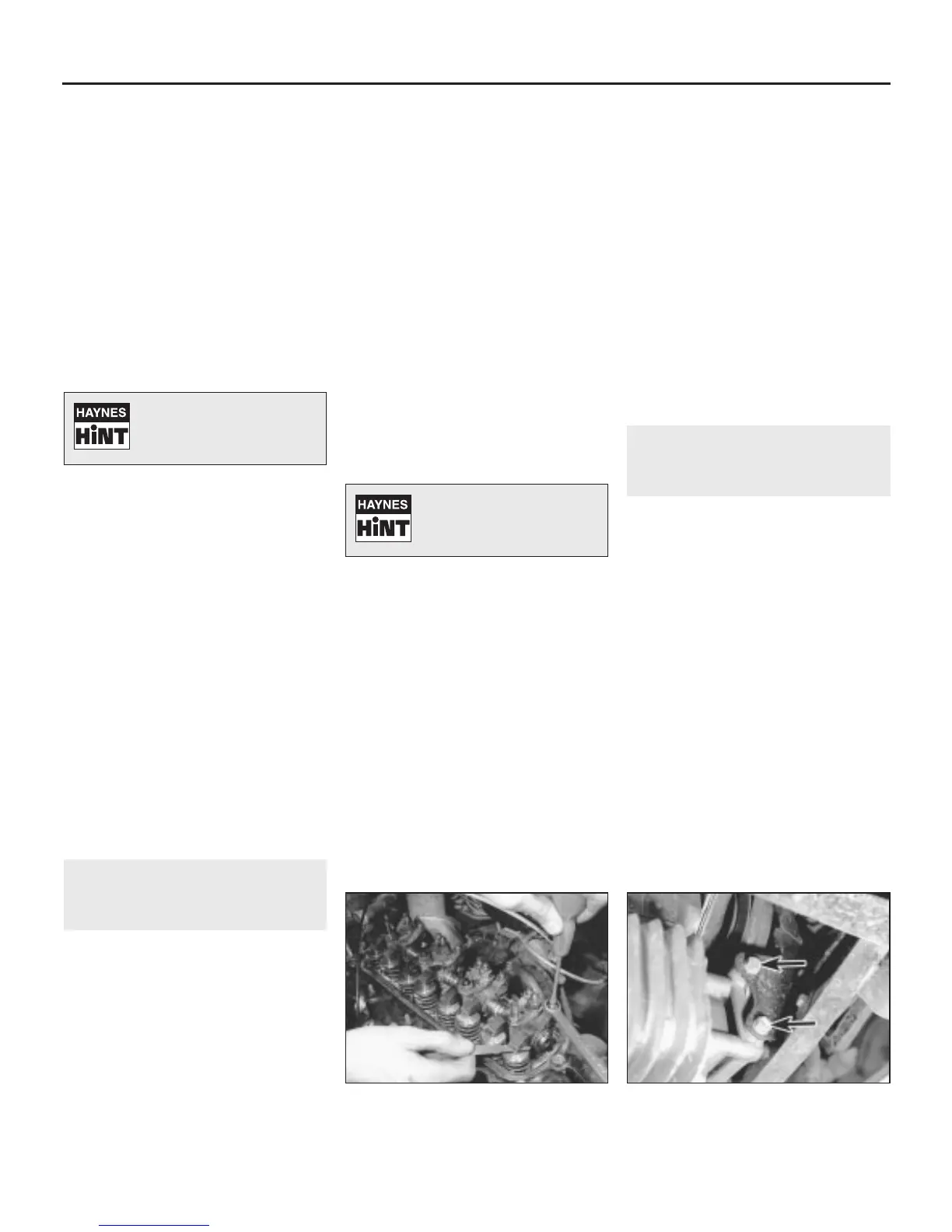

5 On later models, it may be necessary to

remove the lower radiator mounting bracket

to gain the necessary clearance to allow

removal of the crankshaft pulley. To do this,

undo the two nuts and bolts, accessed from

underneath the wheel arch, securing the left-

hand engine mounting to the subframe.

Position a jack with interposed block of wood

beneath the engine/transmission and carefully

lift the jack until the engine/transmission is

raised slightly. Undo the nuts and through-

bolts securing the mounting bracket to the

transmission, and remove the bracket

assembly from the vehicle (see illustration).

6 Bend back the locking tab of the crankshaft

pulley locking washer under the crankshaft

pulley retaining bolt, prising it back with a cold

2A•4 Engine in-car repair procedures

5.5 Left-hand mounting bracket

attachment bolts (arrowed) on later

manual transmission models

4.5 Adjusting the valve clearances

Turning the engine will be

easier if the spark plugs are

removed first - see Chapter 1.

Turning the engine will be

easier if the spark plugs are

removed first - see Chapter 1.

Loading...

Loading...