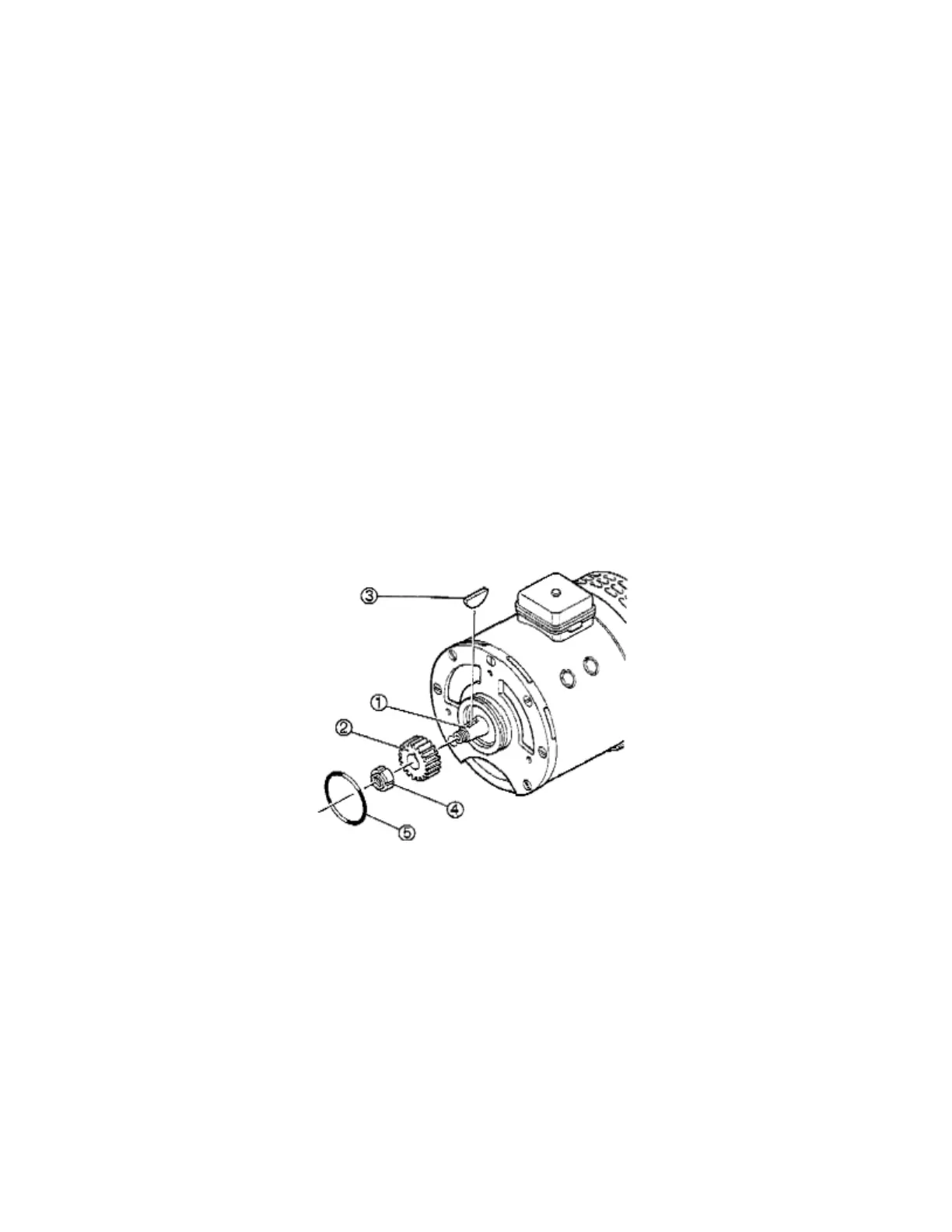

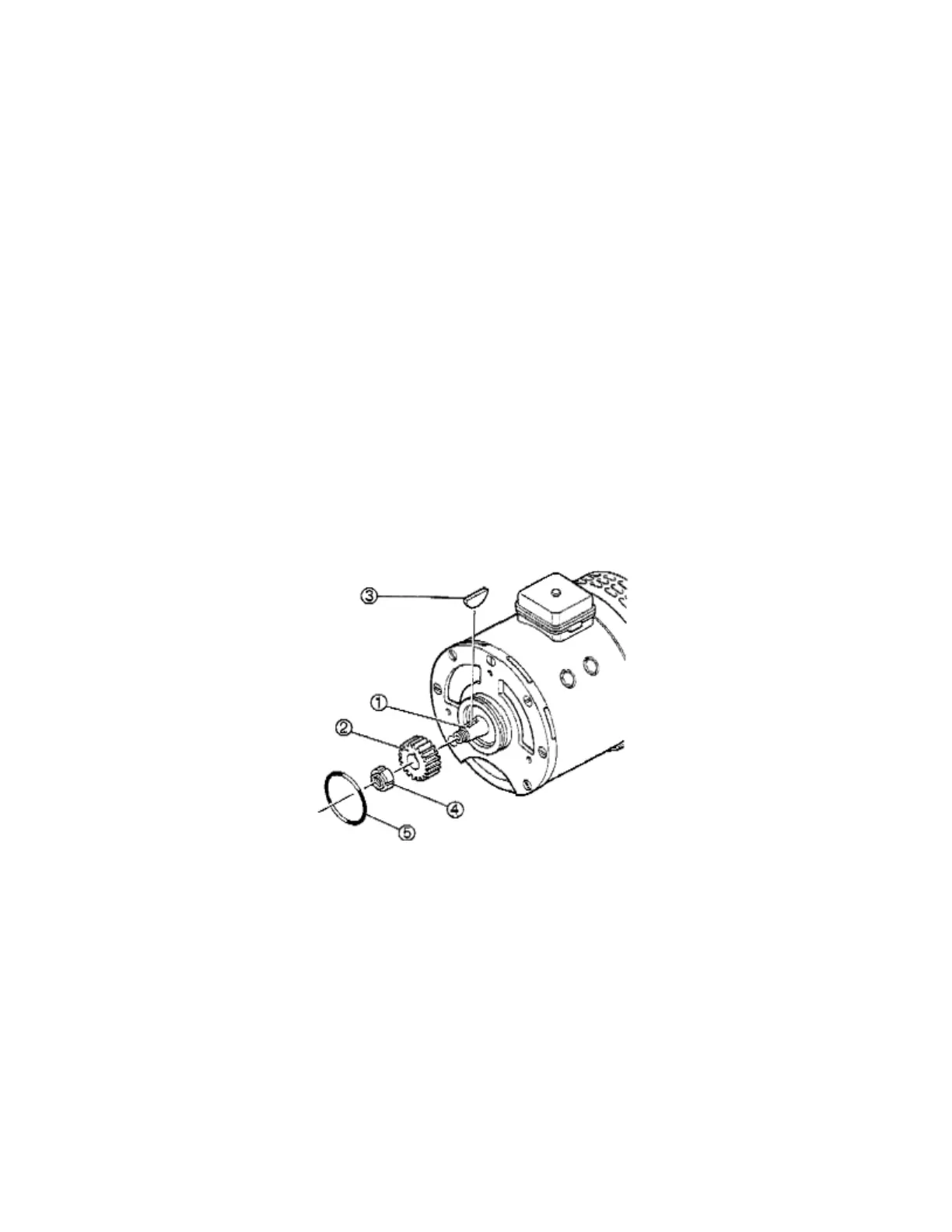

14

(3) Screw a new stopping nut (part 4) on and tighten with socket wrench. Tightening

torque:55 Nm(M20 × 1,taper φ 25);68 Nm(M14 × 1.5,taper φ 20)

(4) Coat O-ring (part 5) slightly with transmission fluid and push it onto centering seat of

motor.

(5)Place the motor carefully on the transmission and join the gearings of motor pinion

and helical gear carefully.

Attention: Do not knock with the drive pinion against the helical gear while

installing the motor. This can cause knocking noise.

(6) Turn motor to coincide bore pattern of transmission with bore pattern of motor.

(7)Screw motor to transmission with three hexagon bolts.(parts1 and 2)(1×M8×50 and

2×M8×75) Tightening torque: 23 Nm.

Figure 1-3

1.3.2 Mounting the transmission unit to the truck frame

Check the frame surface for damage and irregularities. The maximum admissible

irregularity in the area of the transmission contour shall be no more than0.1mm.Screw

drive unit with 7 hexagon bolts M14 and shims to frame. Refer to figure 1-1.

1.3.3 Assembling of wheels

The axle is applicable to solid tyre.

Loading...

Loading...