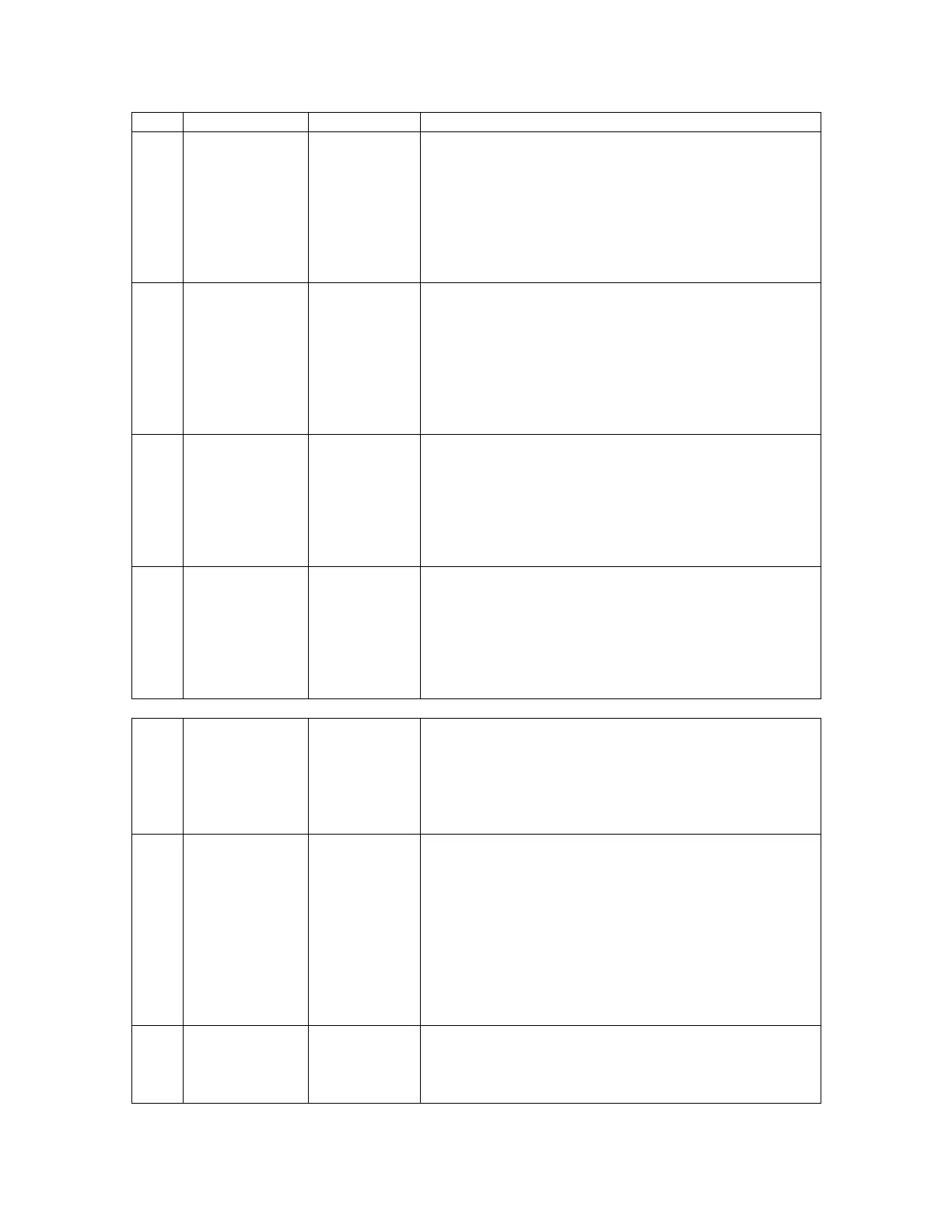

41

Forward and

backward

signals exist

at the same

time(adhesion

of direction

switch )

The machine will keep on detecting. But when there are

signals requesting operation from two directions at the

same time, alarm is given. Possible causes:

(1) The wire is damaged.

(2) Direction switch fault.

(3)Improper operation.

(4) Change the controller if the trouble still can not be

eliminated.

The controller detects the great difference between two

consecutive speed readings of encoder. As the encoder in

the system can not change great speed within very short

time, so, the encoder may have the trouble (the circuits of

one or two encoders are destroyed or broken). Check the

mechanical and circuit function of the encoder. The alarm

is possibly caused by the electromagnetic noise on the

bearing of sensor. If not, change the controller.

Programming

error of

accelerator

If “2.5 POT” is set as “ON”, controller will check the

max. and min values of potentiometer recorded during

programming. If the min. value of forward is smaller than

the max. value of backward or the min. value of backward

is bigger than the max. value of forward, the fault will

appear. Check if the potentiometer is correct, or make a

data acquisition again.

In CAN communication network, a controller receives a

signal that the other controller can not make normal

communication and the controller always is always in the

waiting state until CAN communication network is

completely normal. Check why the wiring of the modules

that fails to communicate is abnormal and see if the

software edition or parameter setting is correct.

During startup, watchdog circuit is activated before

software is started. The watchdog signal is invalid in

standby or operation state( alarm state)

Fault analysis:Hardware circuit of watchdog or output of

micro-controller is damaged. The above two cases have

nothing to do with external parts, so change the controller.

Short circuit

of auxiliary

coil

When the electromagnetic brake connecting to the output

terminal of CNA#18IS or auxiliary coil is shorted, the

fault signal is produced. Withdraw from the fault state

through releasing brake after eliminating the overload

condition so that the running request is valid.

Fault analysis:Generally, the fault code indicates that the

trouble is on the harness or loading coil. So check the

connection between controller output and load first. If

there is no trouble of external load, the trouble is inside

the controller and the controller needs to be changed.

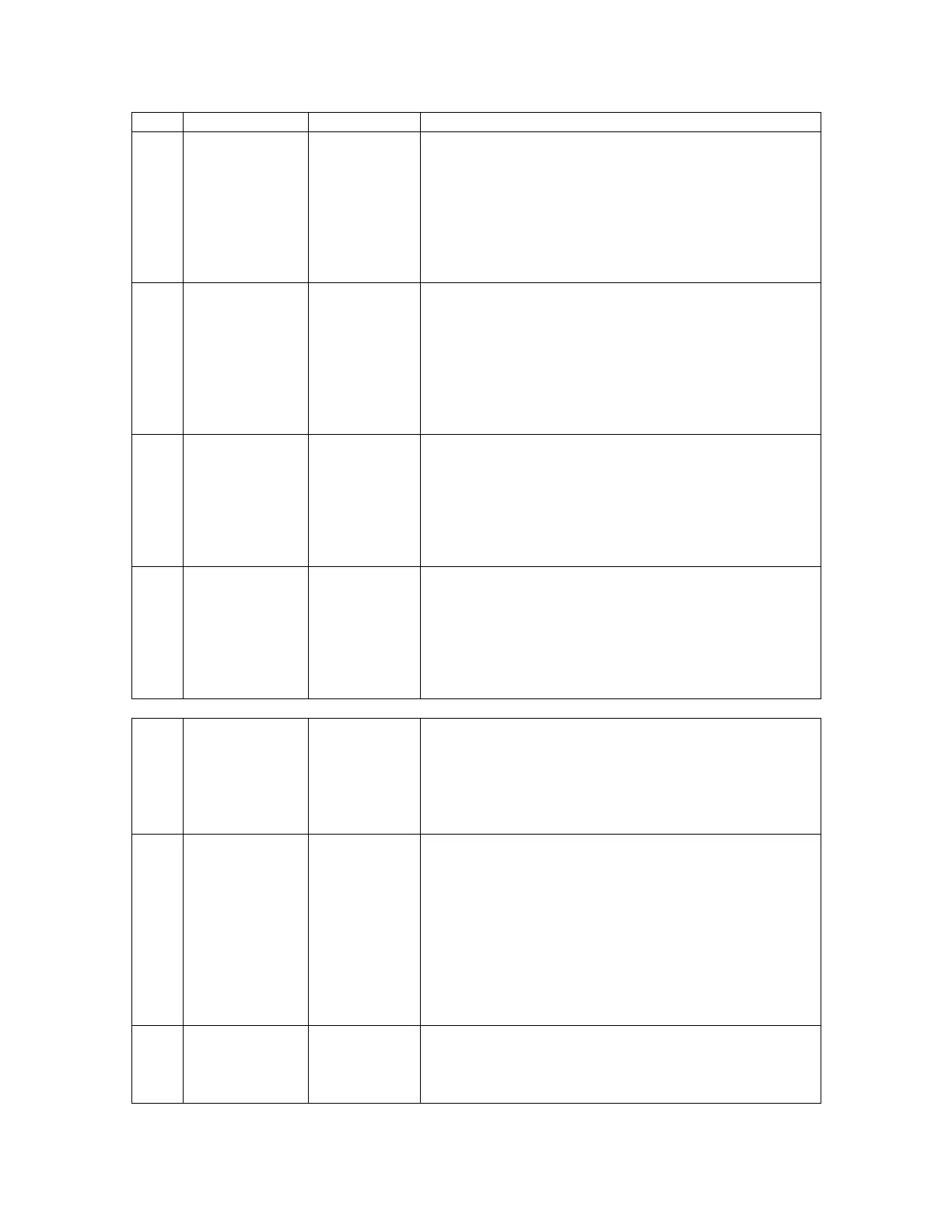

Cause:During startup, the watchdog circuit is activated

before software is started. The watchdog signal is invalid

(alarm state)in case of standby or operation state.

Fault analysis: The hardware circuit of watchdog or

Loading...

Loading...