Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

info@henning-gmbh.de

www.henning-gmbh.de

www.henning-cnc.de

Operating Instructions Elevator Buffers LP Page 5 Edition 3.3.1 EN of 03.04.2017

7.2 Oil level check

The elevator buffers series LP are equipped

with a sight glass as an oil indicator. Therefore,

the buffer does not need to be opened for the oil

level check! This inspection should only be car-

ried out with fully extended piston rod (see a/m

point 7.1).

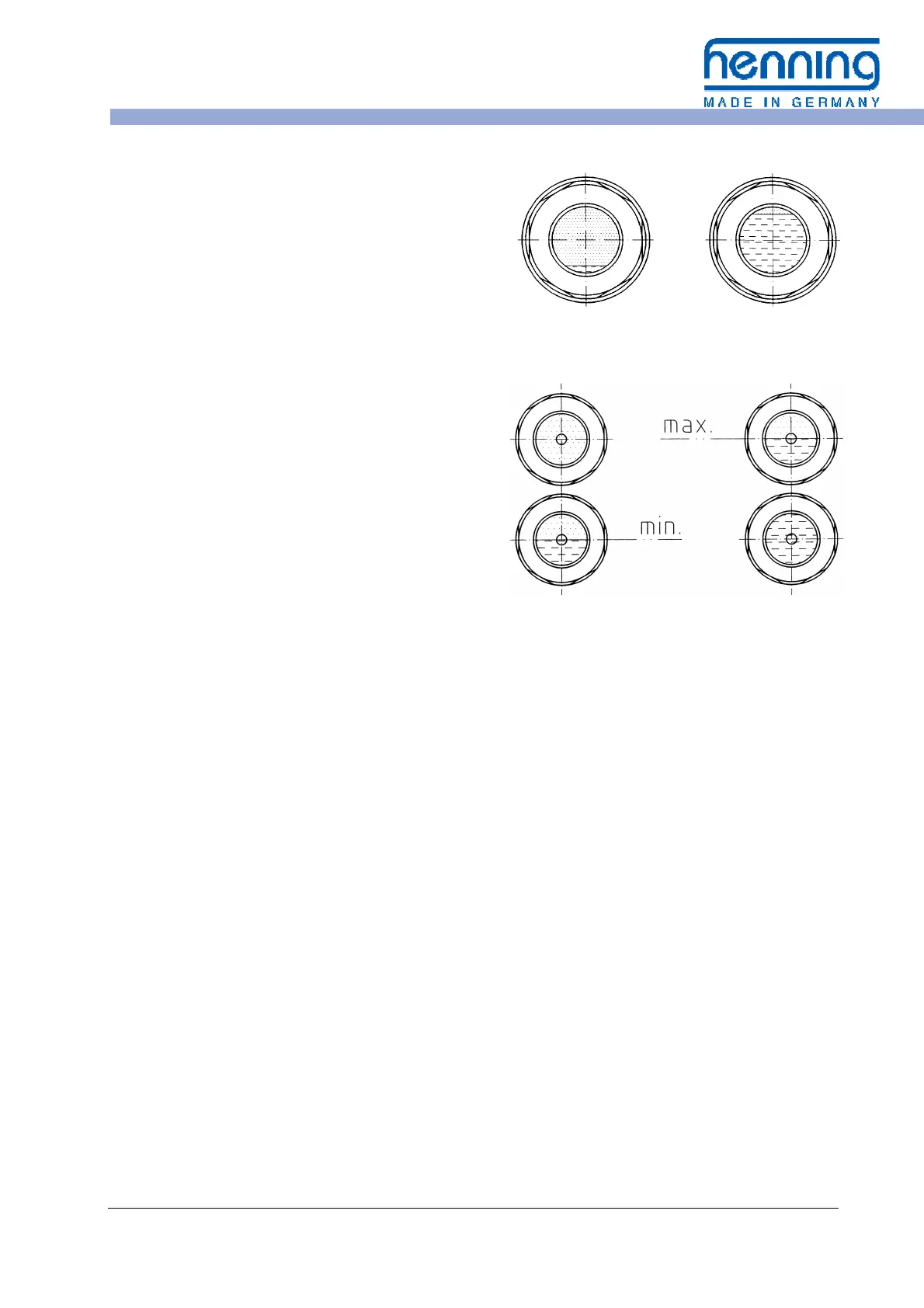

a) Buffer with one sight glass

The oil level should be visible in the

sight glass 9, see Fig. 2a

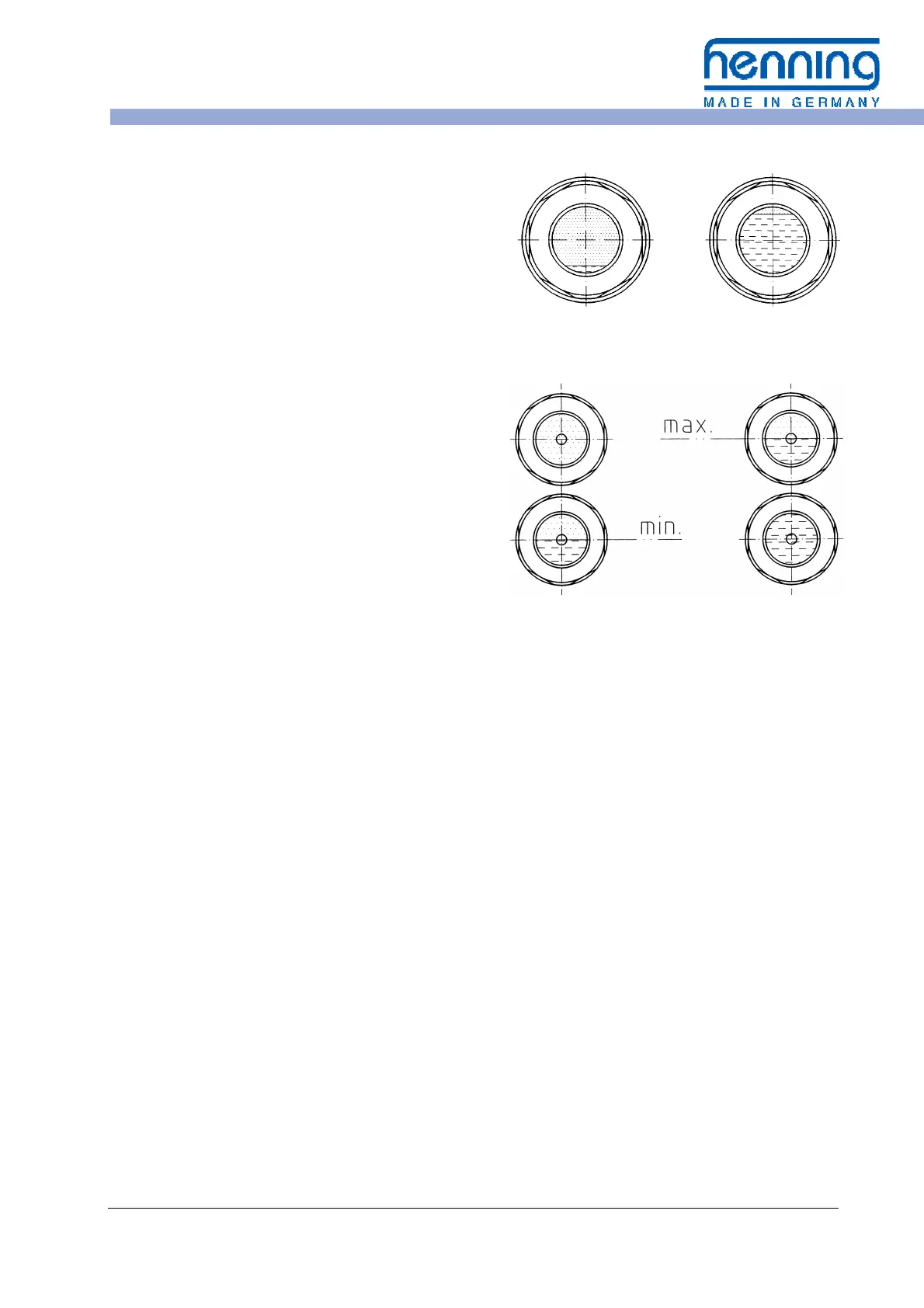

b) Buffer with two sight glasses

- minimum: the oil level is visible in

the lower sight glass

- maximum: the oil level is below the

top edge of the upper

sight glass

see Fig. 2b

Factory oil filling for buffers with one sight glass

is up to the centre of the sight glass (at ambient

temperatures of 16 °C to 22 °C).

Factory oil filling for buffers with two sight glass-

es is below the top edge of the upper sight

glass.

The oil level is depending on temperature. At

ambient temperatures around freezing point, the

oil level can drop near the minimum. High ambi-

ent temperatures let the oil level rise.

If during the oil level check the oil level is found

to be too high, air bubbles might be in the oil. In

this case first press the piston rod of the (upright

standing) buffer several times as far as possible.

If the oil level is not falling although the piston

rod is fully extended, oil must be removed.

If the oil level is too low, oil must be added (see

point 8.3 "Correction of the oil level"). In this

case check the buffer for leakage.

7.3 Gas pressure check

For resetting the piston rod after a buffer stroke

the buffer is filled with nitrogen. The gas pres-

sure at extended piston rod is 5 bar.

The gas pressure may be checked without using

a measuring instrument. For this purpose press

the piston rod by hand for some centimetres.

If the piston rod then returns automatically to its

initial position, the gas pressure is sufficient.

Otherwise proceed as described under point 8.4

"Gas refilling".

7.4 General visual inspection

Pay attention to oil spots on the floor or on the

buffer. An oil film on the piston rod 2 is normal.

Check the piston rod surface for damage and

tightly adherent contaminations.

Check the state and function of the limit

switch 13.

If leaks or damage is found, the buffer must be

exchanged or repaired.

Oil level minimum Oil level maximum

Fig. 2a: Oil level indication with one sight glass

Oil level minimum Oil level maximum

Fig. 2b: Oil level indication with two sight glasses

Loading...

Loading...