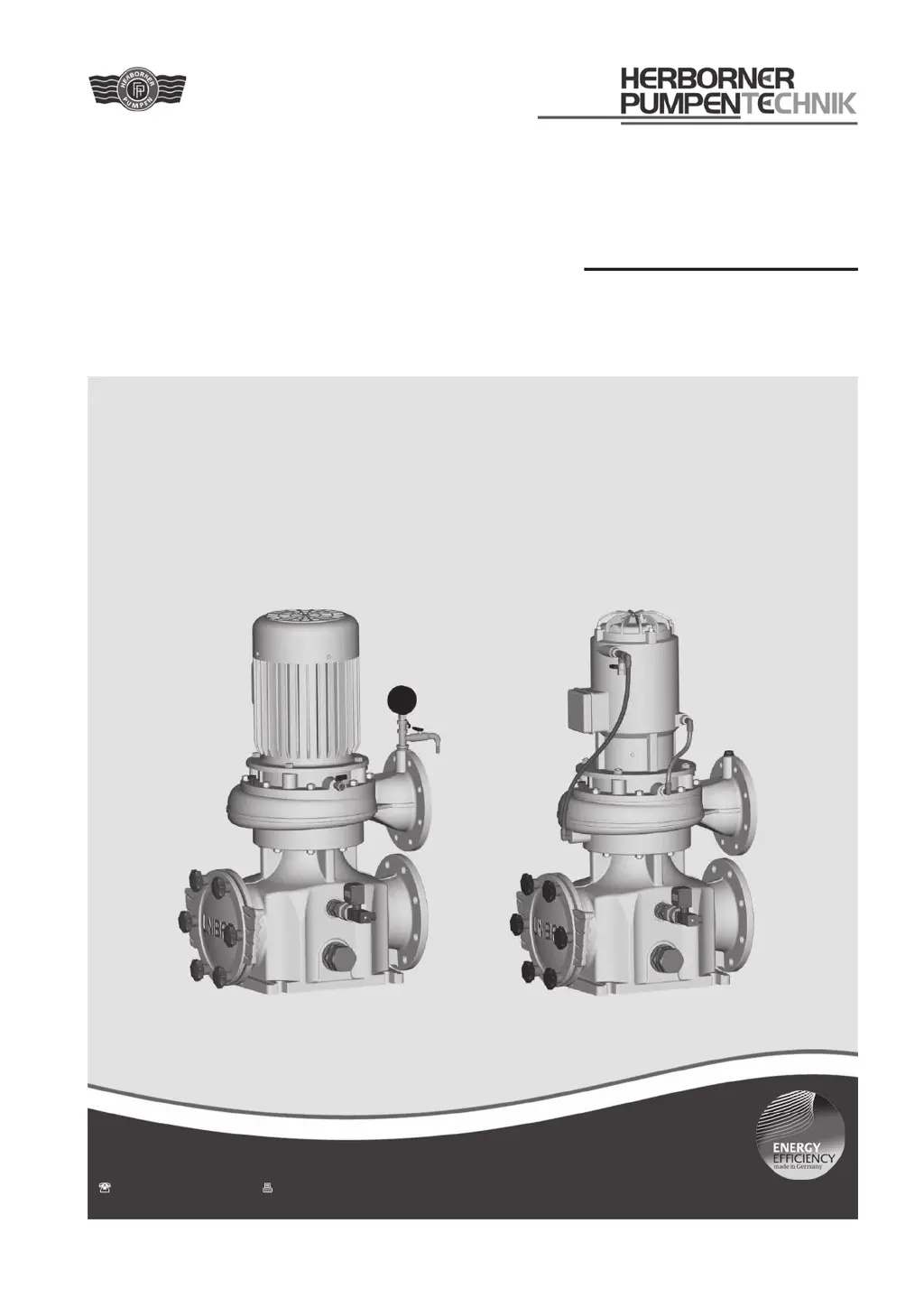

Why is the delivery of my HERBORNER pumpentechnik UNIBAD-X too low?

- VvalenzuelachristopherAug 2, 2025

If the HERBORNER pumpentechnik Water Pump delivery is too low, it may be due to several reasons. The density of the pumped medium might be too high, in which case you should dilute the medium or alter the process. Alternatively, the pump might be working against high pressure, so you should measure the pressure and check the pump layout. Ensure that the gate valves are fully open and that the pipeline and pump are not obstructed. Also, verify the pump is not running on two phases by checking the connections or exchanging the defective locking device. Finally, inspect the impeller for wear or looseness and replace it if necessary.