SERVICE BRAKE (HYDRAULIC BRAKE) BR02–17

IMPORTANT POINTS-ASSEMBLY

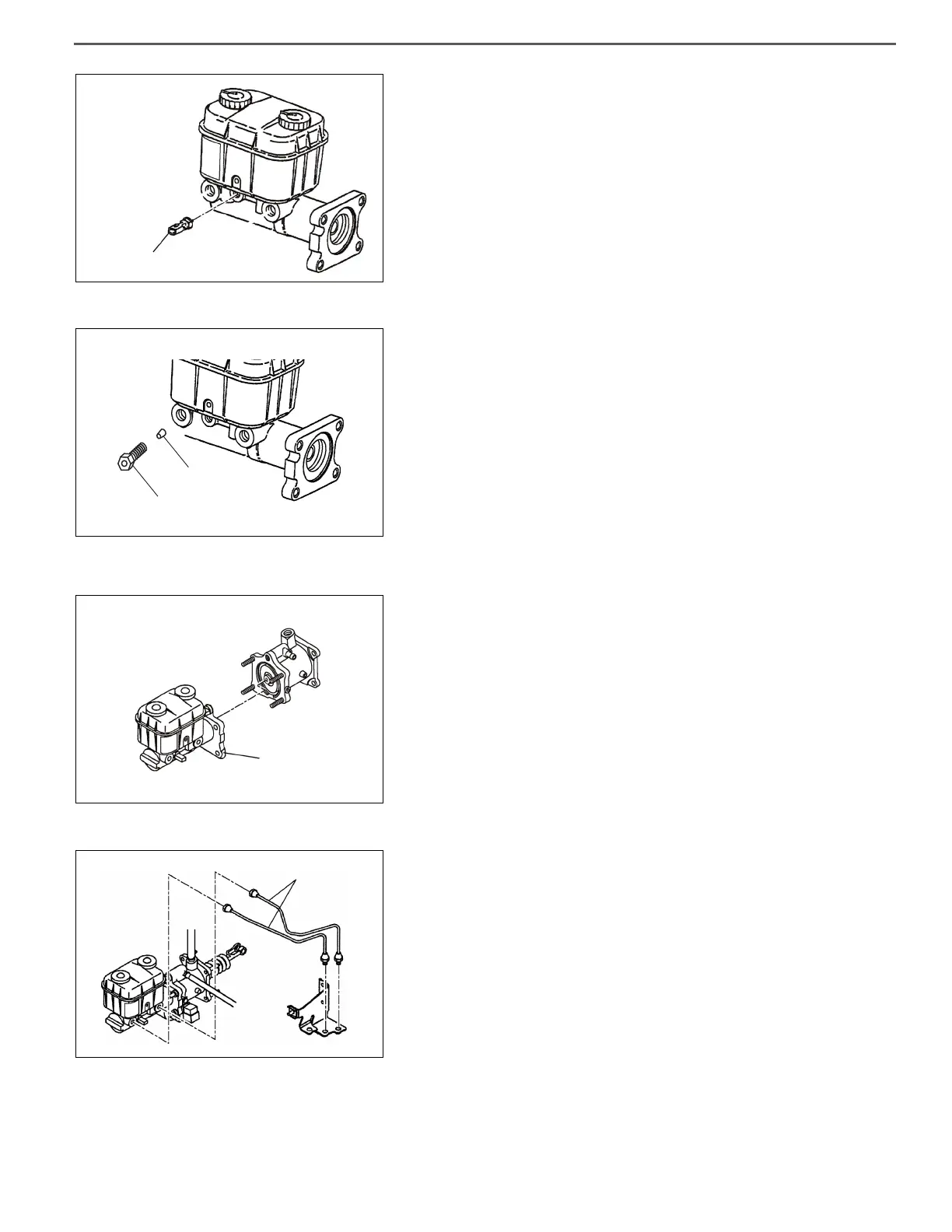

1. INSTALL THE PRESSURE DIFFERENTIAL SWITCH

Tightening Torque:

1.1-1.7 Nm {11-17 kgfcm, 9.7-15 lbfin.}

2. INSTALL THE TUBE SEAT

(1) If the tube seat was removed, install the new parts.

Press the tube seat by using a tube nut.

Make sure the seat is completely inserted in the bottom.

(2) Check installation condition of the sealing surface.

If necessary, clean and rinse the master cylinder ports to remove any

metal fragments.

IMPORTANT POINTS-MOUNTING

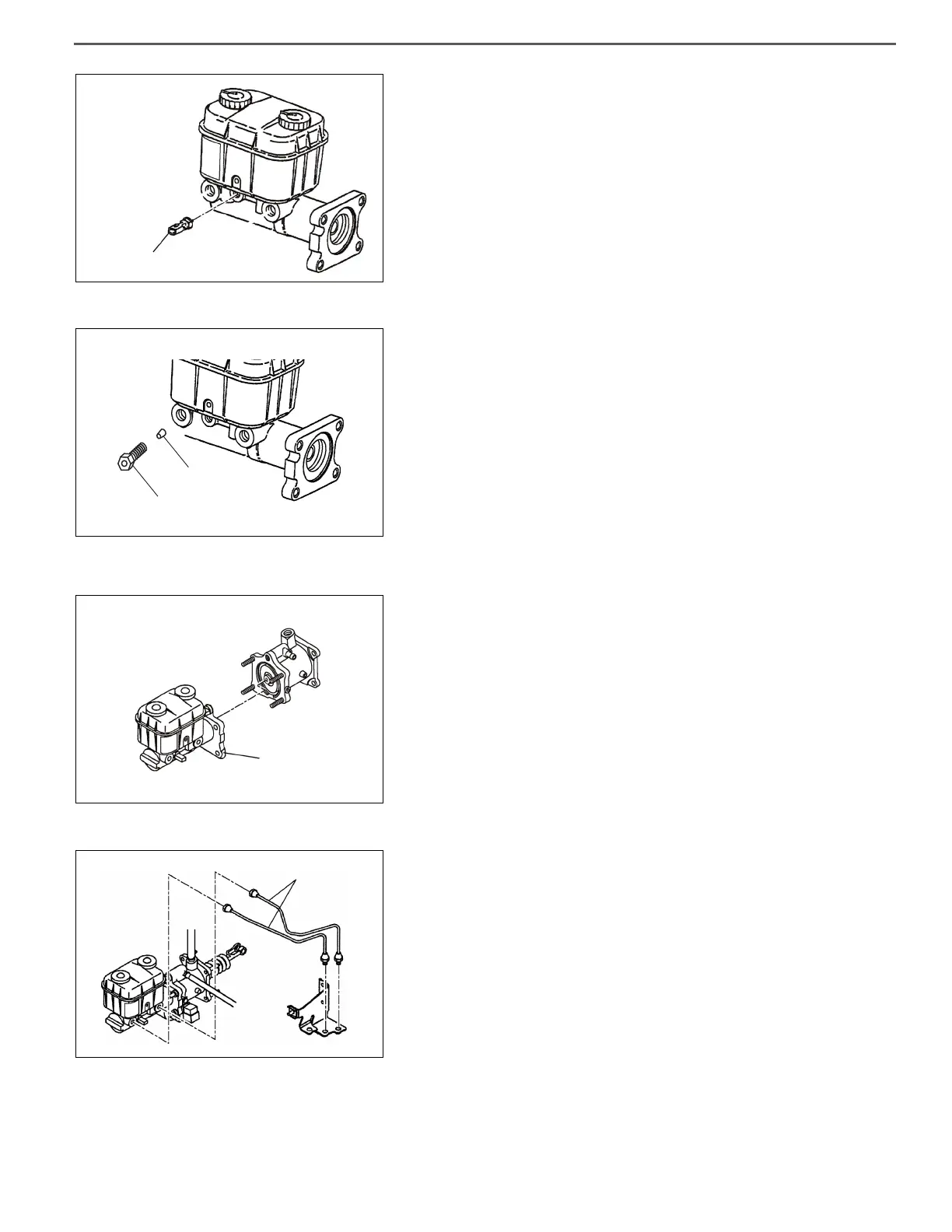

1. CONNECT THE MASTER CYLINDER

(1) Connect the master cylinder to Hydro-Max booster.

(2) Tighten the nut.

Tightening Torque:

33.9-40.7 Nm {346-415 kgfcm, 25-30 lbfft}

2. CONNECT THE BRAKE PIPES

(1) Remove cover from the pipe end.

(2) Connect the brake pipe to the master cylinder.

Tightening Torque:

20-30 Nm {204-305 kgfcm, 15-22 lbfft}

3. BRAKE SYSTEM AIR BLEEDING

Refer to BRAKE SYSTEM AIR BLEEDING of chapter "BRAKE

EQUIPMENT (MODELS WITH HYDRAULIC BRAKE)" BR01-9.

Pressure differential switch

Master cylinder

Loading...

Loading...