The two basic types of snap rings are machined and stamped snap rings.

Machined snap rings (Figure 2) can be installed in either direction. Because both faces

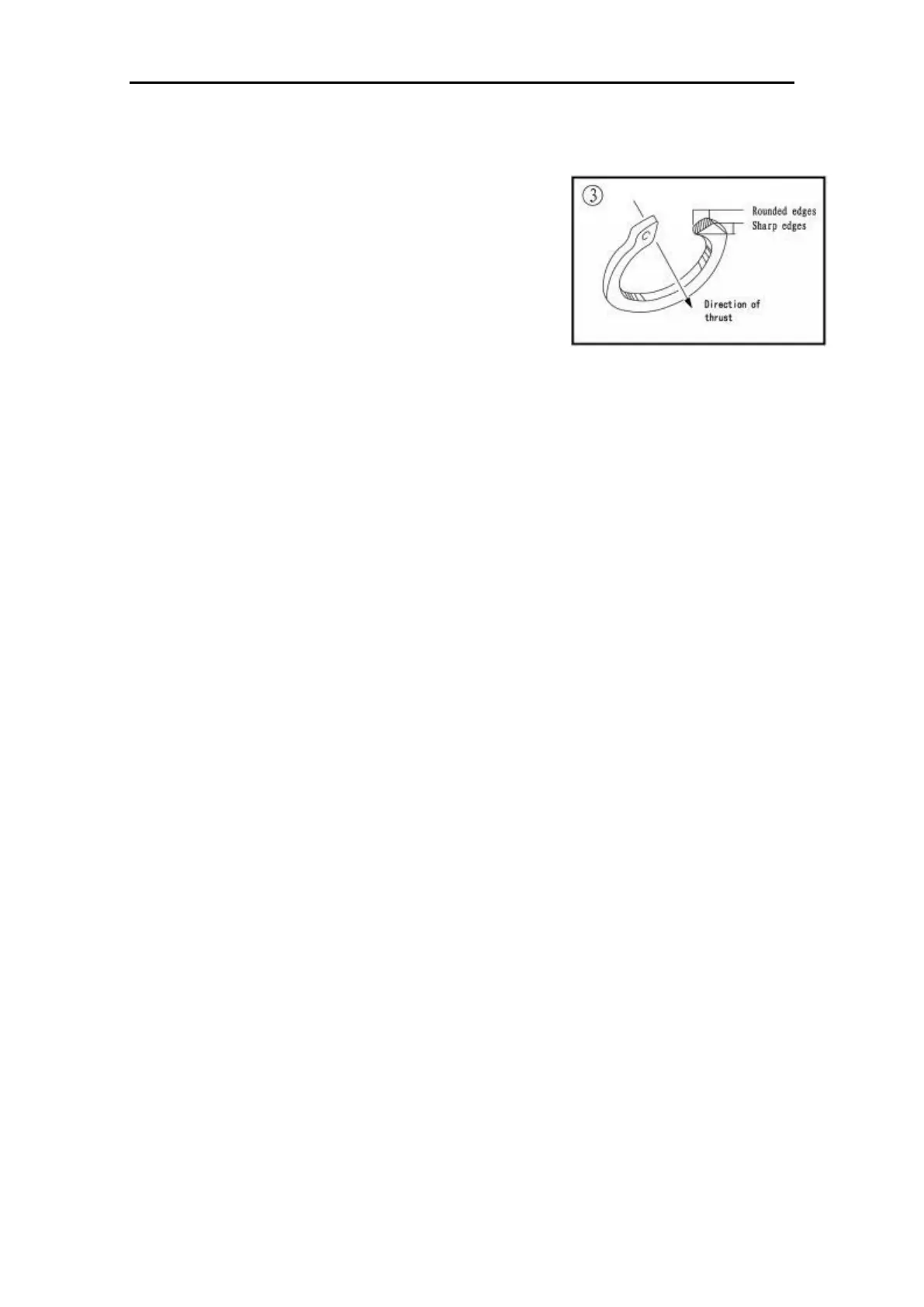

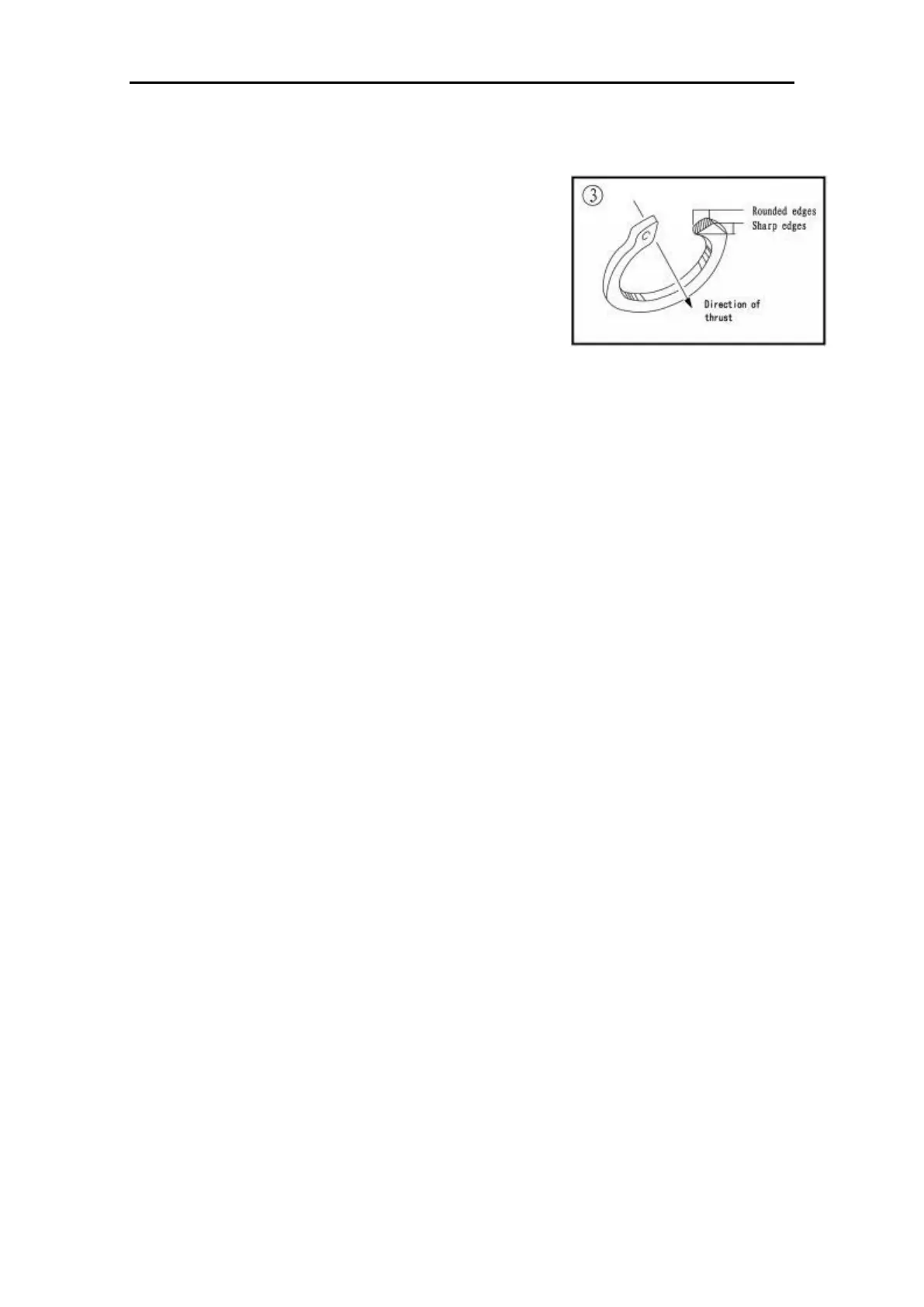

have sharp edges. Stamped snap rings (Figure 3) are manufactured with a sharp and

a round edge. When installing a stamped snap ring in a

thrust application, install the sharp edge facing away

from the part producing the thrust.

E-clips are used when it is not practical to use a

snap ring. Remove E-clips with a flat blade screwdriver

by prying between the shaft and E-clip. To install an E-

clip. Center it over the shaft groove and push or tap it

into place

Observe the following when installing snap rings:

1. Remove and install snap rings with snap rings pliers. Refer to Basic Tools in this

chapter

2. In some applications. it may be necessary to replace snap rings after removing

them

3. Compress or expand snap rings only enough to install them. If overly expanded.

Lose their retaining ability

4. After installing a snap ring. Make sure it seats completely

5. Wear eye protection when removing and installing snap rings

SHOP SIPPLIES

Lubricants and Fluids

Periodic lubrication help ensure a long service life for any type of equipment. Using

the correct type of lubricant is as important as performing the lubrication service.

Although in an emergency the wrong type is better than not using one, The following

section describes the types of lubricants most often required. Make sure to follow the

manufacturer’s recommendations for lubricant types

Engine oils

Engine oil for four-stroke the UTV engine use is classified by two standards: the

American Petroleum Institute (API) service classification. The Society of Automotive

Engineers (SAE) viscosity rating Standard classification

The API and SAE information is on all oil container labels. Two letters indicate the

API service classification. The number or sequence of numbers and letter (10W-40SG

for example) is the oil’s viscosity rating. The API service classification and the SAE

viscosity index are not indications of oil quality.

The APL service classification standards, The first letter in the classification S

indicates that the oil is for gasoline engines. The second letter indicates the standard

the oil satisfies .

The classifications are: MA (high friction applications) and MB( low frication

applications).

Loading...

Loading...