As with wrenches. a 6-point provides superior-holding ability. While a 12-point socket

needs to be moved only half as for to reposition it on the fastener

Sockets are designated for either hand or impact use. Impact sockets are made of

thicker material for more durability. Compare the size and wall thickness of a 19-

mmhand socket (A, Figure 9) and the 19-mm impact socket (B). Use impact sockets

when using an impact driver or air tools. Use hand sockets with hand-driven

attachments

WARNING

Do not use hand

sockets with air or

impact tools because

they may shatter and

cause injury. Always

wear eye protection

when using impact or

air tools

Various handles are available for sockets. Use the

speed handle for fast operation. Flexible ratchet heads in varying length allow the

socket to be turned with varying force and at odd angles. Extension bars allow the

socket setup to reach difficult areas. The ratchet is the most versatile. It allows the user

to install or remove the nut without removing the socket

Sockets combined with any number of drivers make them undoubtedly the fastest.

Safest and most convenient tool for fastener removal and installation

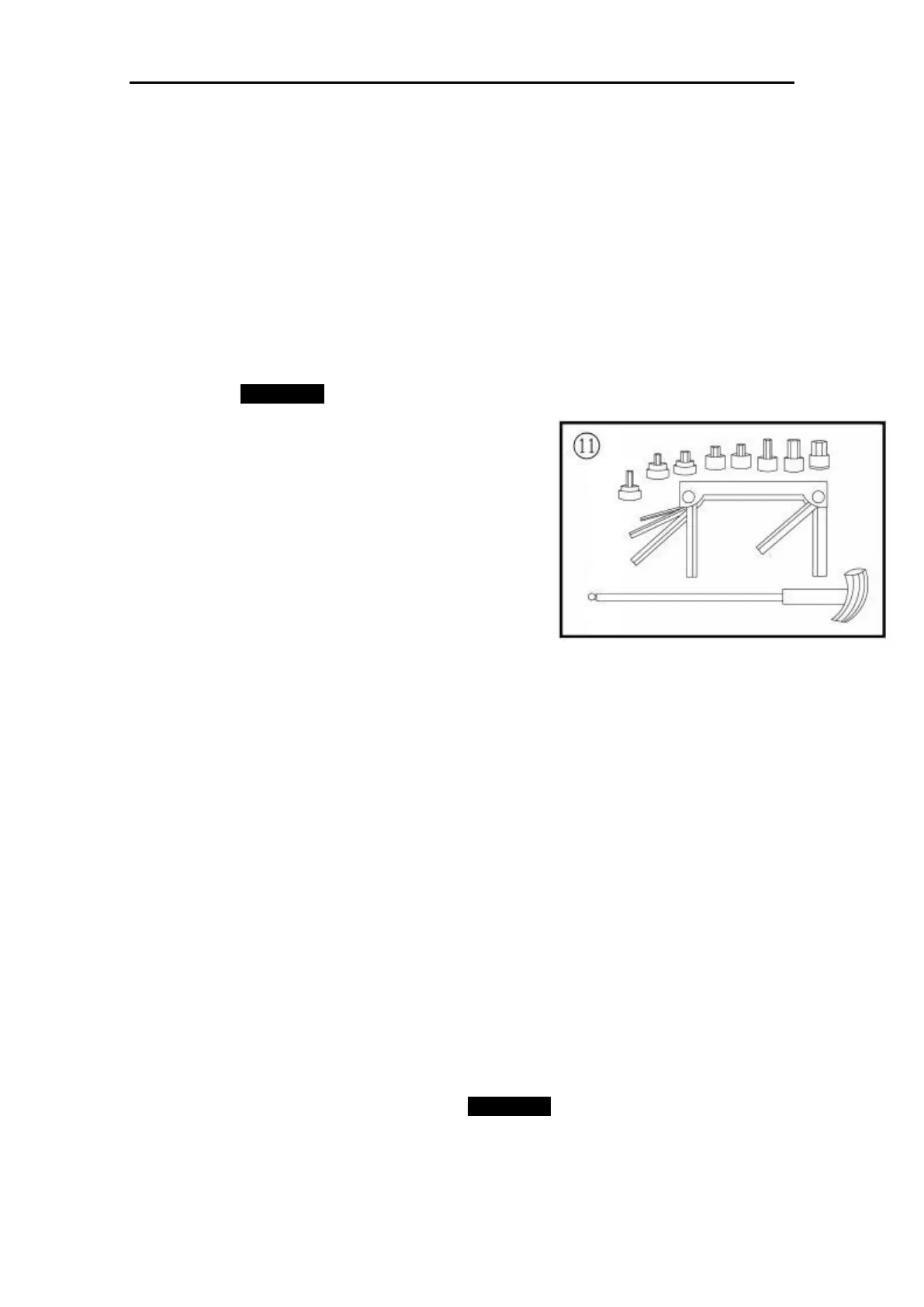

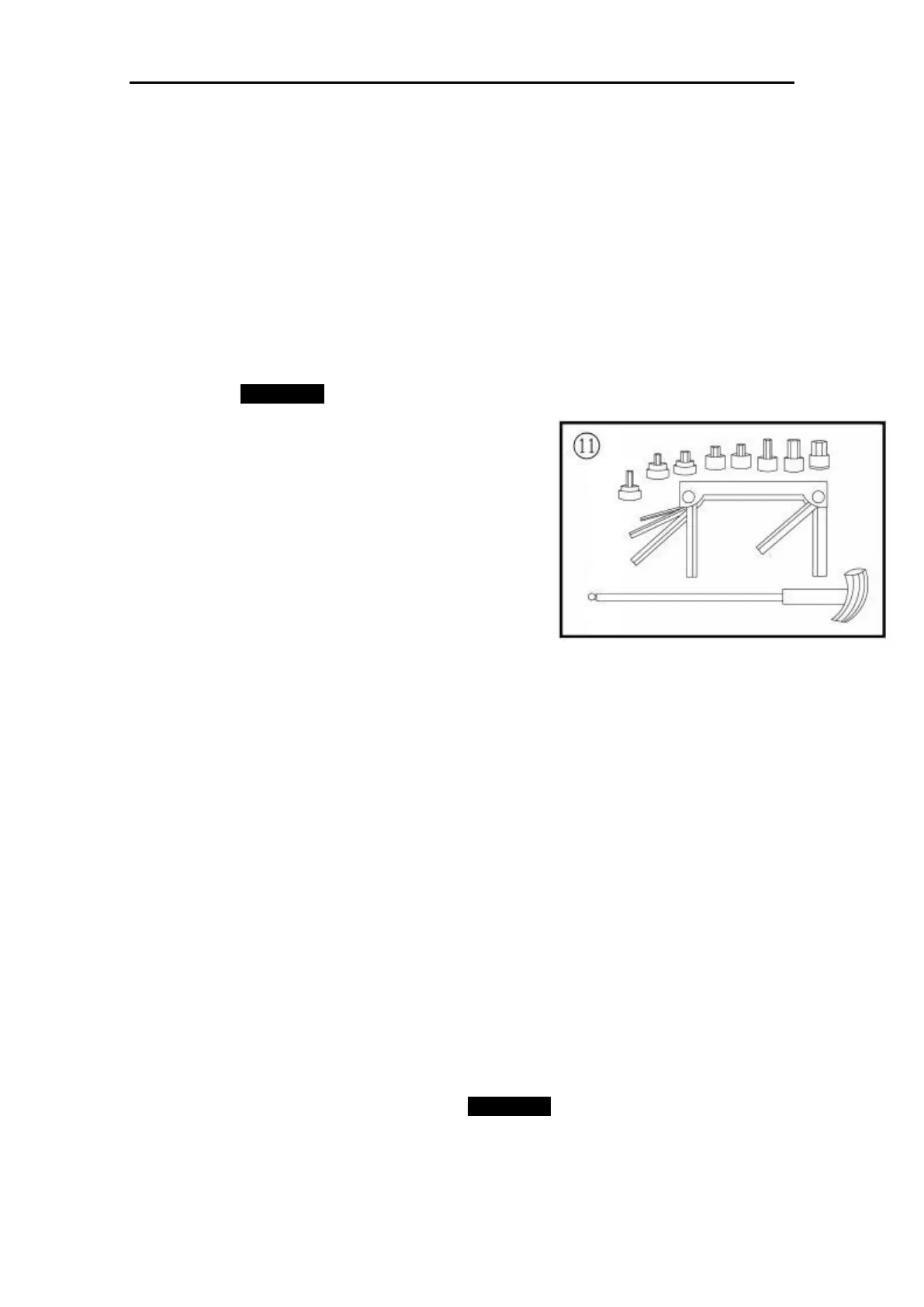

Impact Drivers

An impact driver provides extra force for removing fasteners by converting the

impact of a hammer into a turning motion. This makes it possible to remove stubborn

fasteners without damaging them. Impact drivers and interchangeable bits (Figure 10)

are available from most tool suppliers. When using a socket with an impact driver.

Make sure the socket is designed for impact use. Refer to Socket Wrenches. Ratchets

and handles in this section.

WARNING

Do not use hand sockets

with air or impact tools

because they may shatter

Loading...

Loading...