2. When installing a bearing as described in Step 1, some type of driver is required.

Never strike the bearing directly with a hammer or it will damage the bearing.

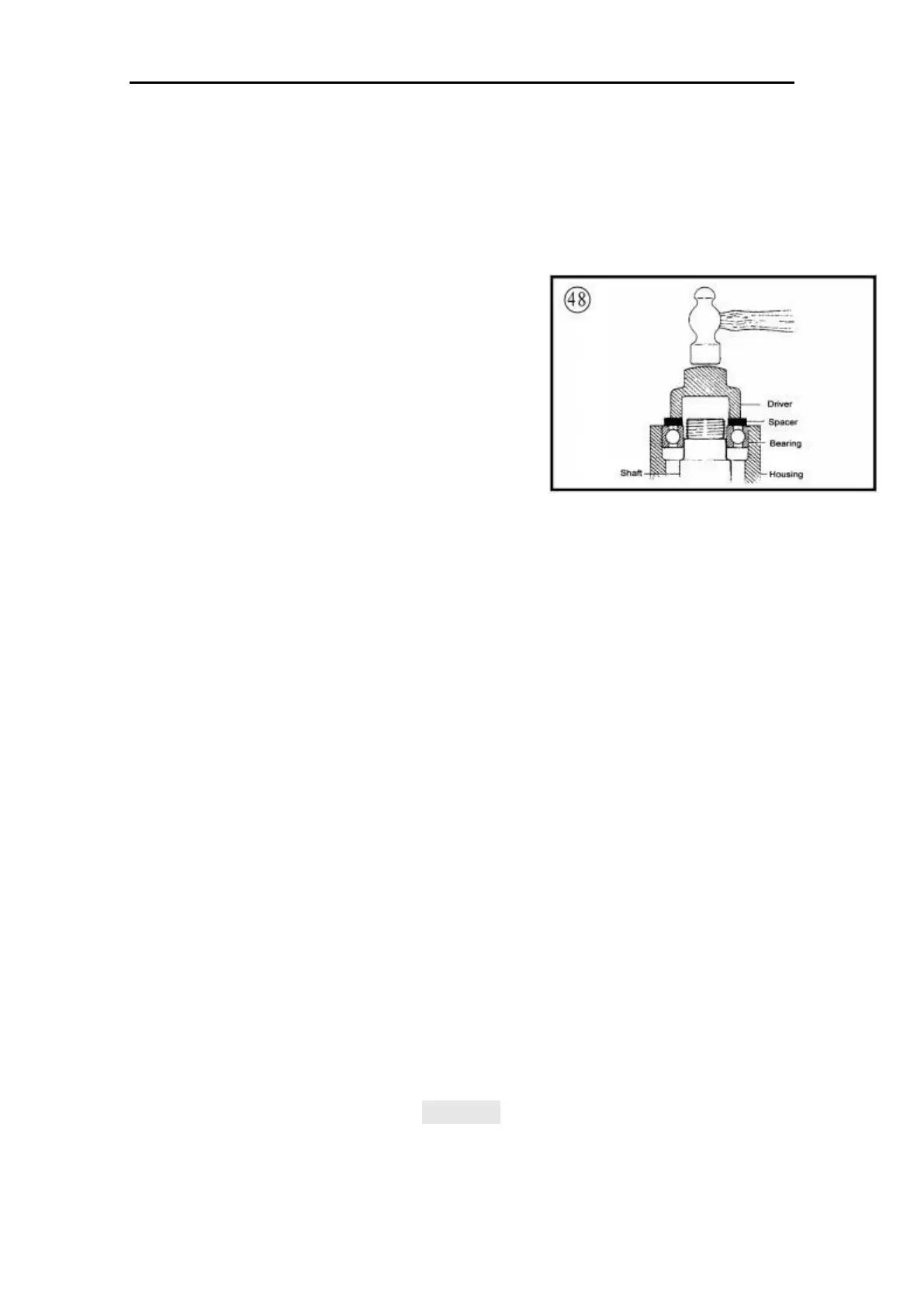

When installing a bearing, use a piece of pipe or a driver with a diameter that

matches the bearing inner race. Figure 47 Shows the correct way to use a driver

and hammer to install a bearing.

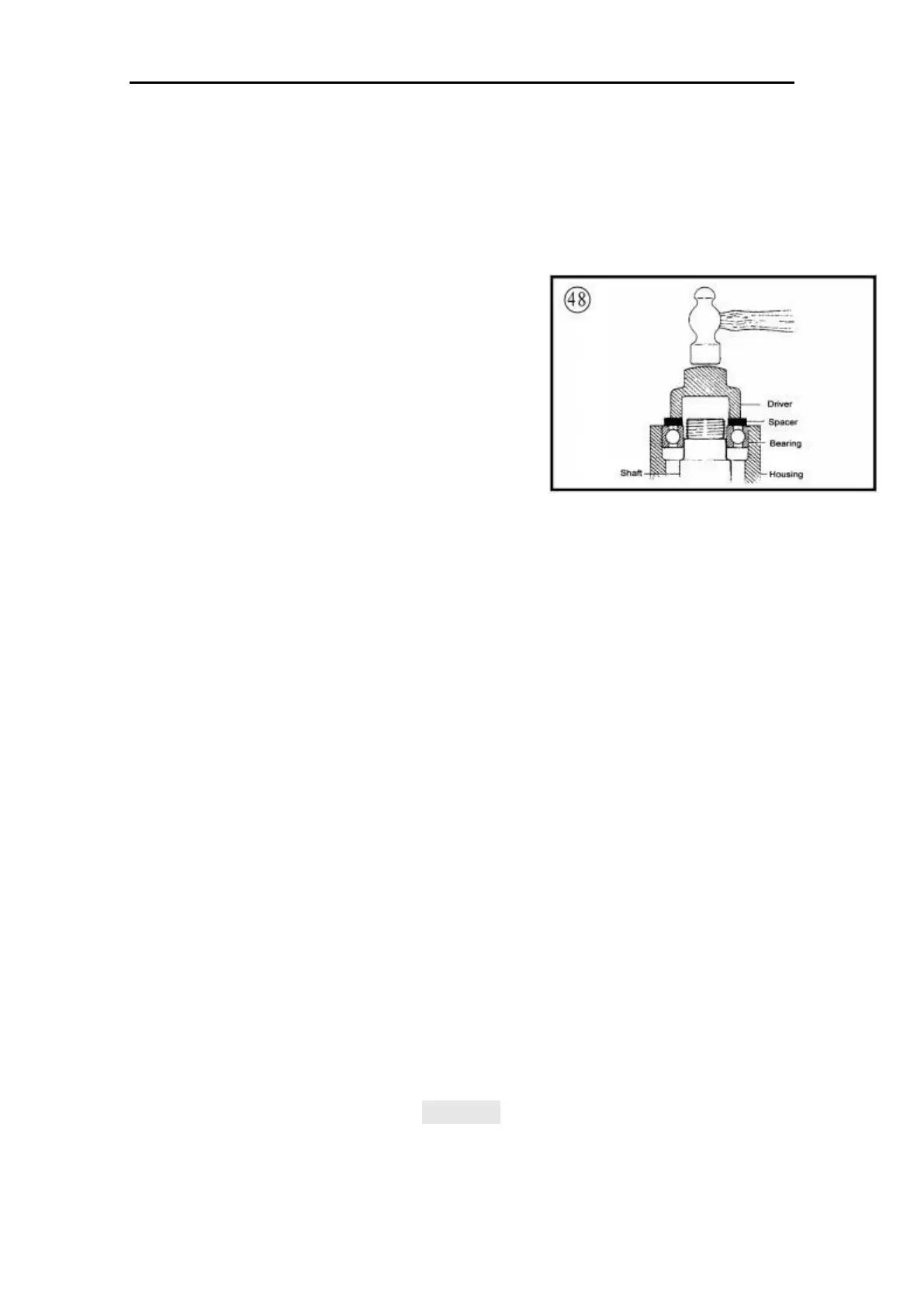

3. Step 1 describes how to install a bearing in a case half or over a shaft However,

when installing a bearing over a shaft and into the housing at the same time, a

tight fit is required for both outer and inner

bearing races. In this situation, install a spacer

underneath the driver tool so that pressure is

applied evenly across both races. See Figure

48. If the outer race is not supported as shown,

the balls will push against the outer bearing race

and damage it

Interference Fit

1. Follow this procedure when installing a bearing over a shaft. When a tight fit is

required, the bearing inside diameter is smaller than the shaft. In this case. Driving

the bearing on the shaft using normal methods may cause bearing damage.

Instead, heat the bearing before installation. Note the following:

a. Secure the shaft so it is ready for bearing installation.

b. Clean all residues from the bearing surface of the shaft. Remove burrs with a

file or sandpaper.

c. Fill a suitable pot or beaker with clean mineral oil. Place a thermometer rated

above 120℃(248°F) in the oil. Support the thermometer so it does not rest on

the bottom or side of the pot.

d. Remove the bearing from its wrapper and secure it with a piece of heavy wire

bent to hold it in the pot. Hang the bearing in the pot so it does not touch the

bottom or sides of the pot.

e. Turn the heat on and monitor the thermometer. When the oil temperature rises

to approximately 120℃(248°F), remove the bearing from the pot and quickly

install it. If necessary, place a socket on the inner bearing race and tap the

bearing into place. As the bearing chills, it will tighten on the shaft, so install it

quickly. Make sure the bearing is installed completely.

2. Follow this step when installing a bearing in a housing. Bearings are general

installed in a housing with a slight interference fit Driving the bearing into the

housing using normal methods may damage the housing or cause bearing

damage. Instead, heat the housing before the bearing is installed. Note the

following:

CAUTION

Before heating the housing in this

procedure, wash the housing

Loading...

Loading...