MAINTENANCE

7-86

17

Check Tightening Torque of Bolts and Nuts

--- every 250 hours (first time after 50 hours)

Check tightness after the first 50 hours then every 250

hours. Tighten to torque shown if any are loose. Bolts and

nuts should be replaced with those of the same or higher

grade.

For tightening nuts and bolts other than specified in

the table below, refer to the Tightening Torque Chart

at the end of this section.

IMPORTANT: Check and tighten bolts and nuts us-

ing a torque wrench.

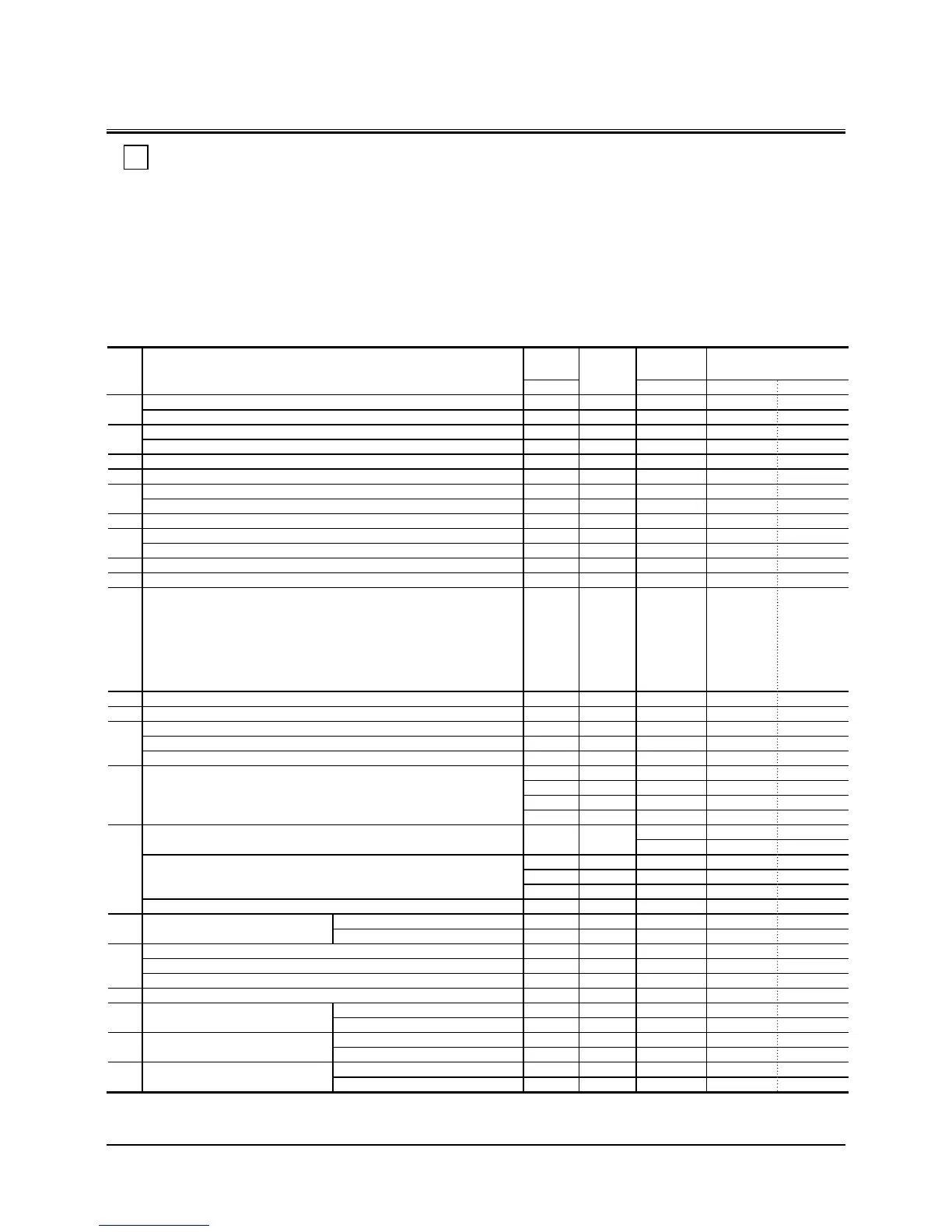

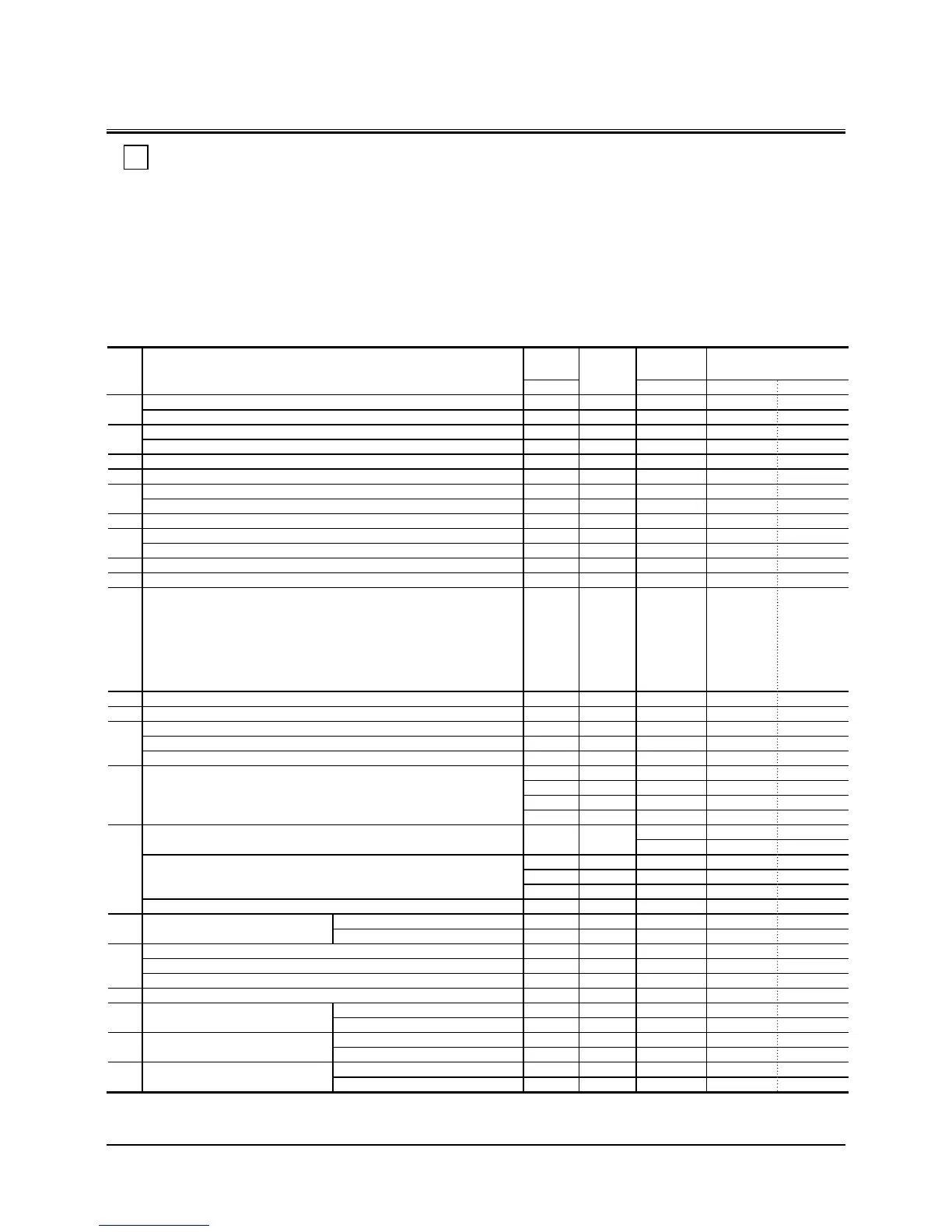

ZX200-3 Class

No. Descriptions

Bolt Dia

Q’ty

Wrench

Size

Torque

mm mm N

•

m (kgf

•

m)

1

Engine cushion rubber mounting bolt and nut (Pump side) 18 4 27 400 (40)

Engine cushion rubber mounting bolt and nut (Fan side) 14 4 22 180 (18)

2

Engine bracket mounting bolt (Pump side) 16 8 24 270 (27)

Engine bracket mounting bolt (Fan side) 10 8 17 65 (6.5)

3 Hydraulic oil tank mounting bolt 20 4 30 550 (55)

4 Fuel tank mounting bolt 16 4 24 270 (27)

5

Radiator mounting bolt (Upper side) 16 4 24 210 (21)

Radiator mounting bolt (Lower side) 16 3 24 210 (21)

6 Pump transmission mounting bolt 10 8 17 65 (6.5)

7

Control valve mounting bolt 16 4 24 210 (21)

Control valve bracket mounting bolt 16 4 24 270 (27)

8 Swing device mounting bolt 20 14 30 500 (50)

9 Swing motor mounting bolt 12 8 10 90 (9)

10 ORS fittings for hydraulic hoses and piping

17 25 (2.5)

19 30 (3)

22 40 (4)

27 95 (9.5)

32 140 (14)

36 180 (18)

41 210 (21)

11 Hycolin tube mounting nut – – 17 35 (3.5)

12 Battery mounting nut 10 4 17 50 (5)

13

Cab mounting nut 16 4 24 210 (21)

Cab mounting anchor bolt 22 2 32 550 (55)

Cab cushion rubber mounting bolt 12 8 19 110 (11)

14 Cover mounting bolt

6 – 10 10 (1)

8 – 13

10 – 17 50 (5)

12 – 19 90 (9)

15

Flexible master coupling of piping

8

1/4-28UNF

4 pairs

13 11 to 13 (1.1 to1.3)

11 6 (0.6)

Jubilee clamp of high pressure piping

9 7 6 (0.6)

11 7 6 (0.6)

4 8 6 (0.6)

T-bolt clamp of high pressure piping 9 10 6 (0.6)

16 Swing bearing mounting bolt to

(Upperstructure) 20 37 30 510 (51)

(Undercarriage) 20 36 30 490 (49)

17

Travel device mounting bolt 20 28 30 630 (63)

Travel reduction device cover mounting bolt 14 12 22 180 (18)

Sprocket mounting bolt 20 32 30 490 (49)

18 Upper roller mounting bolt 16 16 24 270 (27)

19 Lower roller mounting bolt

ZX210-3 18 64 27 460 (46)

ZX210LC-3, 210LCN-3, 240N-3 18 72 27 460 (46)

20 Track shoe mounting bolt

ZX210-3 20 368 27 820 (82)

ZX210LC-3, 210LCN-3, 240N-3 20 392 27 820 (82)

21 Track guard mounting bolt

ZX210-3 18 8 27 500 (50)

ZX210LC-3, 210LCN-3, 240N-3 18 16 27 500 (50)

Loading...

Loading...