8

SPLIT SYSTEMS VERSION

REFRIGERANT LINES

CONNECTIONS AND

REFRIGERANT CHARGE

Units are shipped from the factory with nitrogen

charge and soldered piping connections. Piping con-

nections should be made by qualified installer.

IMPORTANT

To connect outdoor with indoor unit always use

degreased and deoxidized copper refrigerant grade

tubes.

When making refrigerant pipes connections it is nec-

essary to respect the following:

- Avoid small radius curves.

- Take away the nitrogen holding charge from the

refrigerant circuit.

- Select the diameter of the copper tubing taking in

consideration the distance between the indoor and

outdoor units and the unit type.

- For soldering, use silver alloy rod and be sure that

it is done in a nitrogen atmosphere.

- Insulate the refrigerant lines to avoid damage and

oxydation.

- Pull a vacuum in the refrigerant circuit till obtain-

ing a pressure of 0.7 mm water gauge (6.9 Pa) and

maintain it for at least 2 hours.

- Charge the refrigerant circuit with the necessary

amount of refrigerant. Refrigerant charge indicated

in the technical manual is sufficient for the outdoor

and indoor units, you have to add the refrigerant quan-

tity needed for the piping, using table 1 in accordance

with the piping length and diameter.

- Check for refrigerant leaks.

ATTENTION

For correct unit performance and longevity never un-

der or overcharge refrigerant.

IMPORTANT

- Never use a compressor as a vacuum pump.

- Liquid refrigerant must never be introduced into the

suction line.

REFRIGERANT LINES SELECTION

When designing refrigerant lines you have to consider

different piping arrangements:

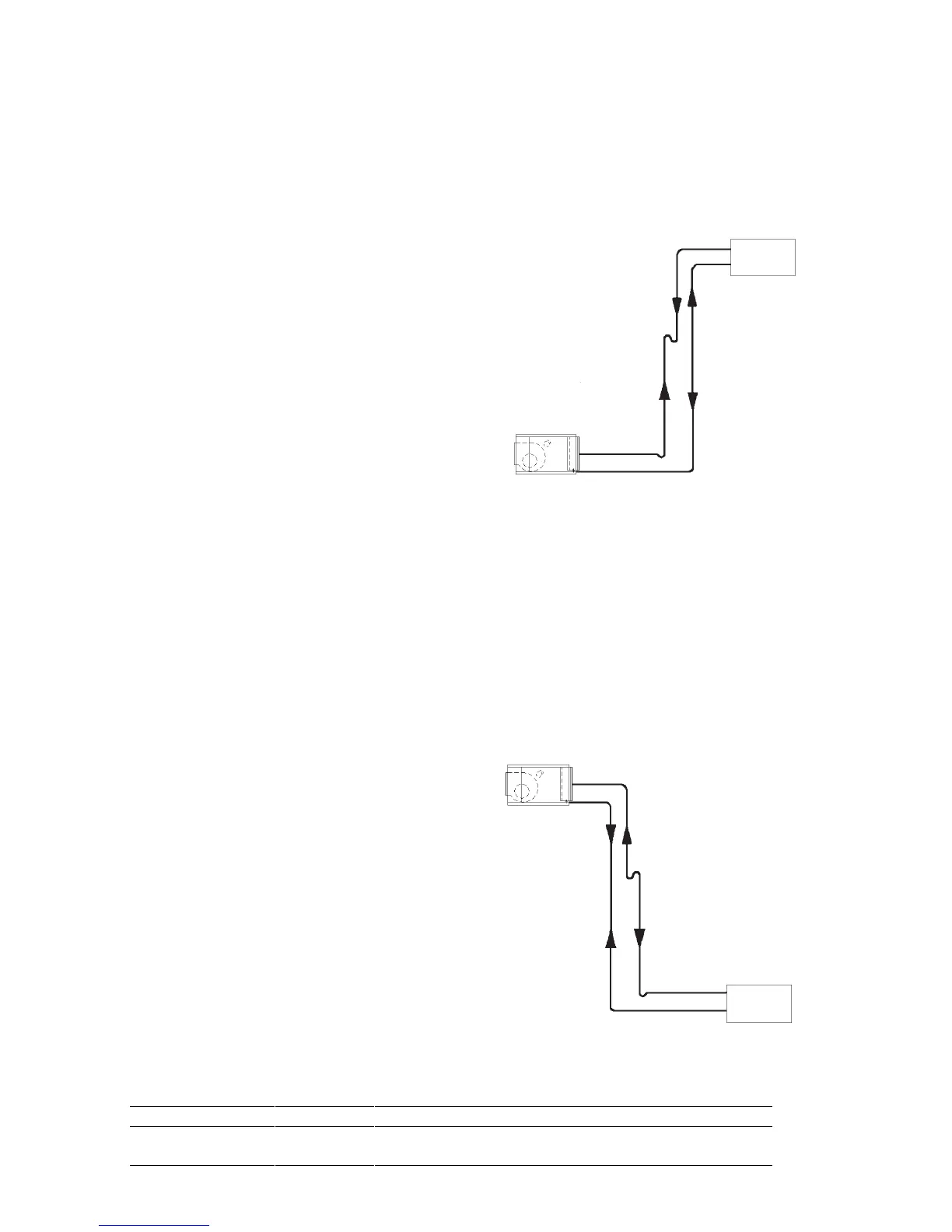

LAYOUT ACCORDING TO FIGURE 2

Suction / discharge line - Vertical run

- A trap at the base of the vertical pipe run and in-

termediate traps every 8 meters.

- Suction line, vertical run: gas velocity should be

more than 6 m/s.

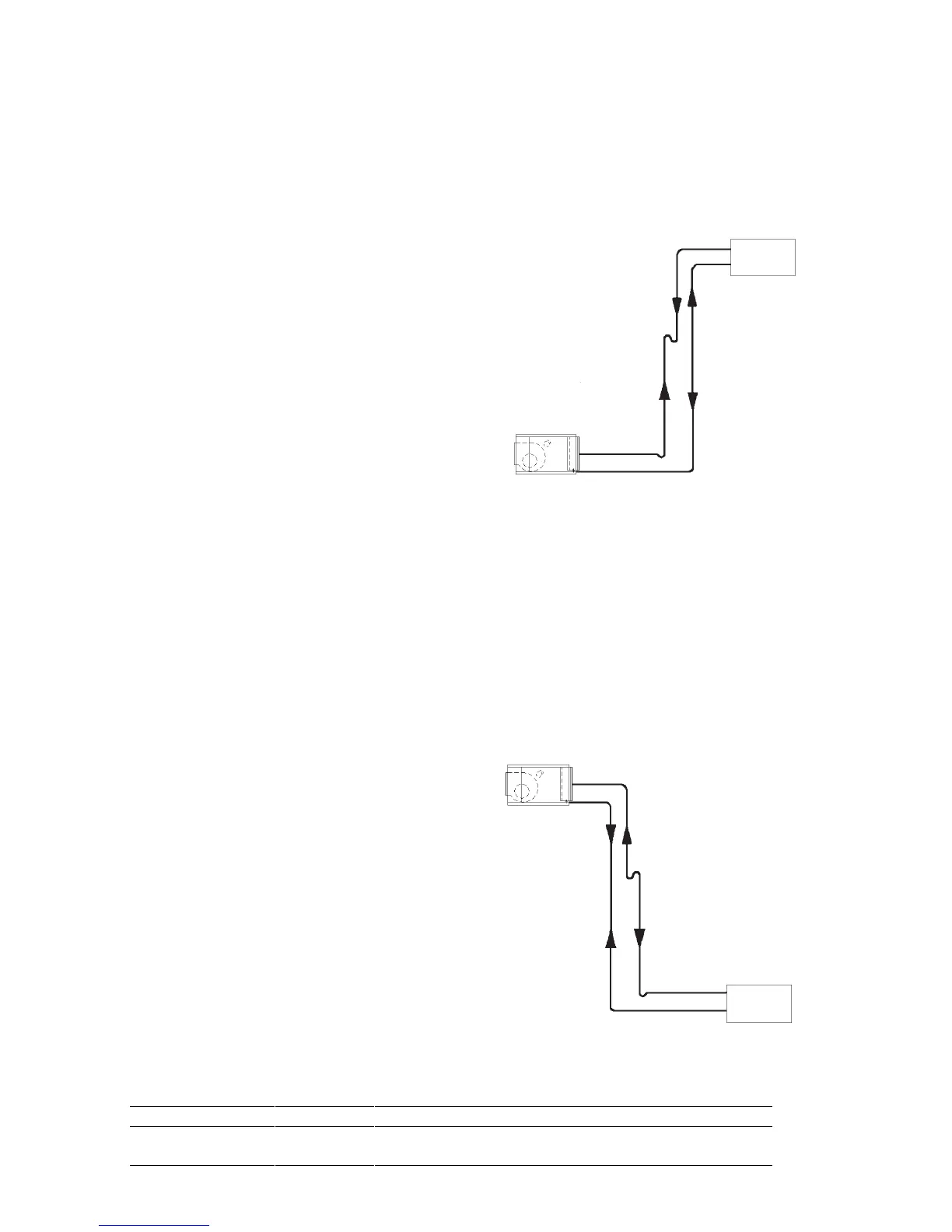

LAYOUT ACCORDING TO FIGURE 3

Indoor

unit

Outdoor

unit

Heat pump Heat pump (discharge line)

Liquid line Gas line

Cooling Cooling (suction line)

Fig. 3 - Outdoor unit is below the indoor unit.

Heat pump Heat pump

(discharge line)

Gas line Liquid line

Cooling Cooling

(suction line)

Fig. 2 - Outdoor unit is installed above the indoor unit.

Outdoor

unit

Indoor

unit

Table 1:ADDITIONAL REFRIGERANT CHARGE (g/m)

Diameter 1/4" 5/16" 3/8" 1/2" 5/8" 3/4" 7/8" 1-1/8" 1-3/8" 1-5/8"

Liquid line 15 25 40 75 120 180 250 420 645 965

Suction line - - 6 14 23 34 47 81 123 185

Loading...

Loading...