SPECIFICATIONS

Frequently Asked Questions (FAQs)

1. What should the TDS readings be?

For drinking water and filter performance, the lower the TDS level, the better. There is never a

“right” or “wrong” number. For filter performance, calculate the percent rejection to determine

performance levels. Contact the manufacturer of your filter system for recommended levels.

2. My TDS levels fluctuate. Is this normal?

Yes. Slight fluctuations are normal from day-to-day. A variety of factors affect the reading.

3. Does the DM-2 have an alarm or programmable set point?

No. You will need to view the readings. Models QC-1, PM-1, FM-2 and others have alarms.

4. How will I know when the batteries need to be replaced?

A low battery indicator, “bat” will appear on the display for 3 seconds when the unit is turned on.

5. Can I use the DM-2 to monitor a water softener?

No. Water softeners do not remove TDS. Models FM-1 or FM-2 are suggested for softeners.

6. Where can I get more information on water quality?

Visit www.hmdigital.com

INSTRUCTIONS

To install the DM-2 to a water purification or filtration system:

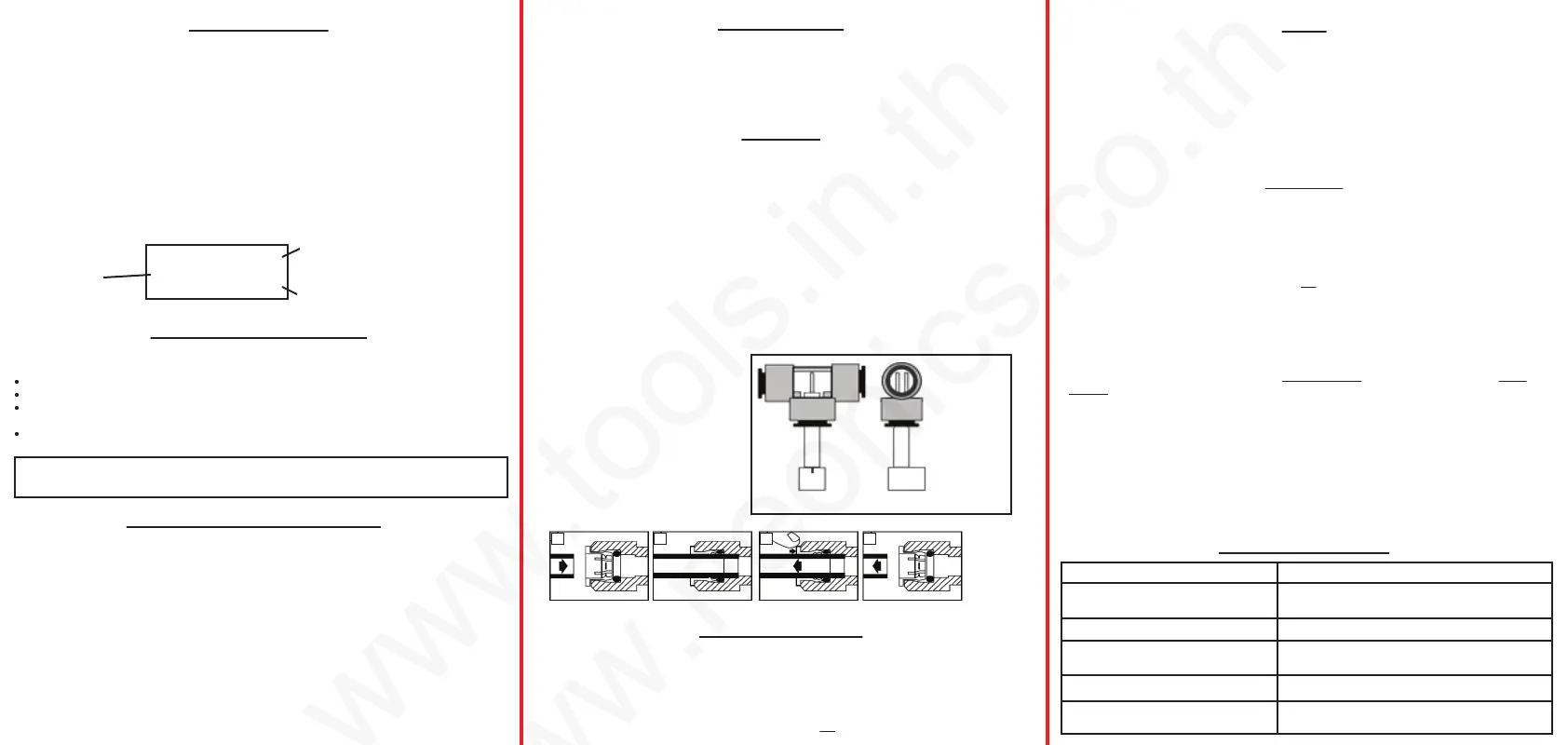

1. Insert the white sensors fully into the bottom of the T-fittings.

2. Orient the sensor pins so that they are perpendicular to the direction of the T. The water

should flow over both pins equally. (You should be able to see both pins of you look

through the fitting.) See illustration #1 below.

3. Disconnect the water source.

4. Snip the source (tap) water tube at a point between the source and the filter. Insert both

ends of the tube into the top of the IN line sensor’s T-fitting. See illustration #2.

5. Snip the product (filtered) water tube at a point between the filter and a dispenser. Insert

both ends of the tube into the top of the OUT line sensor’s T-fitting. See illustration #2.

6. The DM-2 monitor can be attached anywhere on or near the water system using the

mounting bracket (which can be secured by screws or the adhesive tape).

7. Reconnect the water source. Your monitor is now ready for use.

NOTE: Consult a professional plumber for specific bracket or connection questions.

Installation

TDS Range: 0-9990 ppm

Resolution: 0-999: 1 ppm

1000-9990: 10 ppm (indicated by a blinking ‘x10’ icon - multiply the reading by 10)

Accuracy: +/-2% (of the reading)

Conversion Factor: NaCl (avg. of 0.5)

Factory Calibration: 342 ppm NaCl (digital calibration)

Sensor Cable Length: 46” (116.8 cm) (including sensor)

Power Source: 2 x AA batteries

Auto Shut-Off: After 3 minutes

Battery Life: Approximately 2 years

Base Unit Dimensions: 4.6 x 2.6 x 0.7 in (11.6 x 6.8 x 1.8 cm)

Base Unit Weight: 7.9 oz (224.3 g) (including batteries)

CARE AND MAINTENANCE

Very little care is necessary for your DM-2.

Never touch the sensor pins, as skin oils may adversely affect the TDS measurement.

To clean the sensor pins, clean with rubbing alcohol and let air dry.

Avoid removing the fittings, as doing this often may strip the plastic off the sensor and potentially

cause a leak.

If you notice the readings are off from what they should be, replace the batteries or re-calibrate.

000

PPM

x10

Screen Description

TDS Level

Parts per million (equivalent to mg/L)

Times 10 indicator

(appears if over 999 ppm)

The DM-2 can be configured in a variety of ways, depending upon your needs.

Typically, the IN line (line 1) is connected to the source (tap) water, and the OUT line

(line 2) is connected to the product (filtered) water. The DM-2 can also be configured

with multiple systems, such as an RO/DI combination, as well as with HM Digital’s

Single Inline TDS Monitor (model SM-1).

Calibration

1. Obtain a certified calibration solution that is correct for your needs. The calibration solution should

be NaCl (sodium chloride). HM Digital’s 342 ppm NaCl solution is recommended.

2. Disconnect both T-fittings from their tubes. Do not remove the sensor from the T. Ensure the

orientation of the sensor to the fitting is correct, as in illustration #1. Shake any water out.

3. For better accuracy, calibrate to a flowing solution. If this is not possible, you can calibrate to a still

solution. (If calibrating to a still (not flowing) solution, calibrate to 3% above the level of the

calibration solution. This will accommodate for the lack of flowing water, which the monitor is

programmed for. For example, if the calibration solution is 342 ppm, calibrate to 352 ppm.)

4. Turn on the monitor and place each T-fitting (with the sensors in them) into the calibration solution.

You will get a reading. Ensure the fitting is completely filled with solution and there are no air

bubbles. This step is critical for proper calibration. If the reading is correct, stop here.

5. If the reading on the monitor (for either line) does not match the solution, select the line you wish

to calibrate (they are calibrated separately) by clicking IN or OUT.

6. Press and hold the IN or OUT button (the side you want to calibrate) for 2 seconds. “CAL” will

flash on the screen and the corresponding green light will blink.

7. Press the up button (IN) or the down button (OUT) to adjust the reading until it matches the value

of your calibration solution. Hold for rapid advancement. Do not move the sensor!

8. Once the reading is correct, press the POWER button once. Wait until “End” appears. This

sensor is now calibrated and will revert to the measurement reading. Each sensor needs to be

calibrated separately.

To cancel calibration, press POWER twice.

Your monitor was factory calibrated to 342 ppm (NaCl). This level is suitable for most tap

water/filtered water applications, so it is ready to use out of the box. However, you may need to

re-calibrate based on your needs, as well as from time-to-time to ensure best results. To calibrate:

Avoid removing the ttings from the sensors. Excessive removal and insertion of the

ttings could ultimately scratch the sensor and potentially cause leakage.

1

12 2

Push tubing straight in as far as it can go. To remove, push in small collet and pull the tubing out.

LOOKING

THROUGH

THE

FITTING

SIDE VIEW

Illustration #1

To insert the sensor

into the fitting.

Illustration #2

To insert the tubing

into the fitting.

1. Press the “POWER” button.

2. To display the TDS level of the feed (tap) water, press the IN button. To display the TDS level of

the product (filtered) water, press the OUT button.

3. The displayed TDS will be most accurate after approximately 10 seconds.

4. Determining filter effectiveness depends on your particular system. For an RO system, for

example, compare the IN water TDS levels with the OUT water TDS.

5. If the “x10” icon appears, then the TDS level is above 999 ppm. Therefore, multiply the reading

by 10. For example, if the display shows 143 ppm with the ‘x10’ icon, the actual TDS level is

1430 ppm. (If the ‘x10’ icon does not appear, the reading on the display is the actual TDS level.)

6. Turn off the unit. (It will automatically shut off after 3 minutes to conserve battery power).

Usage

TROUBLESHOOTING

ECC display (error)

Incorrect readings

6AE display (low batteries)

The “OUT” reading is higher than

the “IN” reading

Issue Potential Solution(s)

1. The sensor cable is unplugged. Open the back

panel and connect the cable securely.

1. Re-calibrate the monitor.

2. Change the batteries.

1. Change the batteries.

1. Check your connections. The sensors may be

reversed.

Changing the Batteries

1. To replace the batteries, unscrew the four metal screws on the rear of the unit and remove the

back panel.

2. Remove the batteries.

3. Replace both batteries with two fresh AA batteries. Ensure the polarity is correct.

4. Close the back panel and replace the screws. You will not need to recalibrate.

If the batteries are low, when the unit is turned on, you will see 6AE (bat) for three seconds.

1. The water is out of the monitor’s TDS range.

OOC display (out of range)

www.tools.in.th

www.neonics.co.th

Loading...

Loading...