ORP-200 01/08

CONTENTS

Overview……………………………………………………………… …...1

Contact Information……………………………………………………..….. 1

Specifications…………………………………………………………...……1

Housing and Screen Description………………………………………….. 2

Taking Measurements……………………………………………………… 3

Calibration…………………………………………………………………… 4

Care, Maintenance & Techniques………………………...……………….5

Warranty……………………………………………………………...……… 7

OVERVIEW

Thank you for purchasing HM Digital’s ORP-200 Meter. The ORP-200 is an advanced, micro-processor-based

handheld, watertight ORP meter with superior accuracy. It can be used for testing the Oxidation Reduction (Redox)

Potential levels of almost any liquid, provided the liquid contains less than 50% alcohol and a conductivity of at least 10

µS. It also measures temperature in both Celsius and Fahrenheit. Though the meter is factory calibrated, it also

features digital calibration for easy and precise calibration that will yield better results.

WHAT IS ORP? ORP, or Redox, describes all chemical reactions in which atoms have their oxidation number (oxidation

state) changed and is thus a measurement of water’s ability to oxidize contaminants. The higher the ORP, the greater the

number of oxidizing agents.

Checking ORP is a simple method to monitor the effectiveness of a sanitizer or the quantity of anti-oxidants in a liquid. In

generalized terms for humans, a higher ORP is better for outside of the body, while a lower ORP is preferred for

consumption due to the high anti-oxidant value. There are numerous applications for ORP, each with its own specific

optimum value. For example, the minimum ORP for pool & spa disinfection (set by the World Health Organization) is 650

mV. [The use of ORP testing in pools and spas should not eliminate nor supersede the use of sanitizer testing with

standard kits.] Though the WHO has not set a standard for ORP in drinking water, anything below -550mV is considered

too strong and not recommended for drinking.

**HM Digital makes no health claims regarding ORP nor the use of ORP testing. It is the responsibility of the

user to consult a professional in the applicable field for all safety and health concerns prior to the use of this

meter.

CONTACT INFORMATION

If you have any problems or questions regarding your meter, please contact HM Digital, Inc.

HM Digital, Inc. info@hmdigital.com

5819 Uplander Way www.hmdigital.com

Culver City, CA 90230 1-800-383-2777

SPECIFICATIONS

ORP Range: -999 to +1000mV

Temperature Range: 1-80 °C; 33-176 °F

Resolution: ORP: 1 mV; Temperature: 0.1 °C/F

Accuracy: 0.5% (+/- 2 mV)

Temperature Compensation: Automatic (ATC) to 25 °C

Calibration: Auto-ranging with digital fine tuning (factory calibrated to +200mV)

Auto Shut-Off: After 5 minutes

Probe: Glass sensor and platinum reference cell encased in glass

Safe Operating Temperature: 1-80 °C; 33-176 °F (measuring in extreme temperatures is not

recommended)

Minimum Conductivity: For accurate and stable readings, the liquid to be tested must have a

conductivity of at least 10 µS

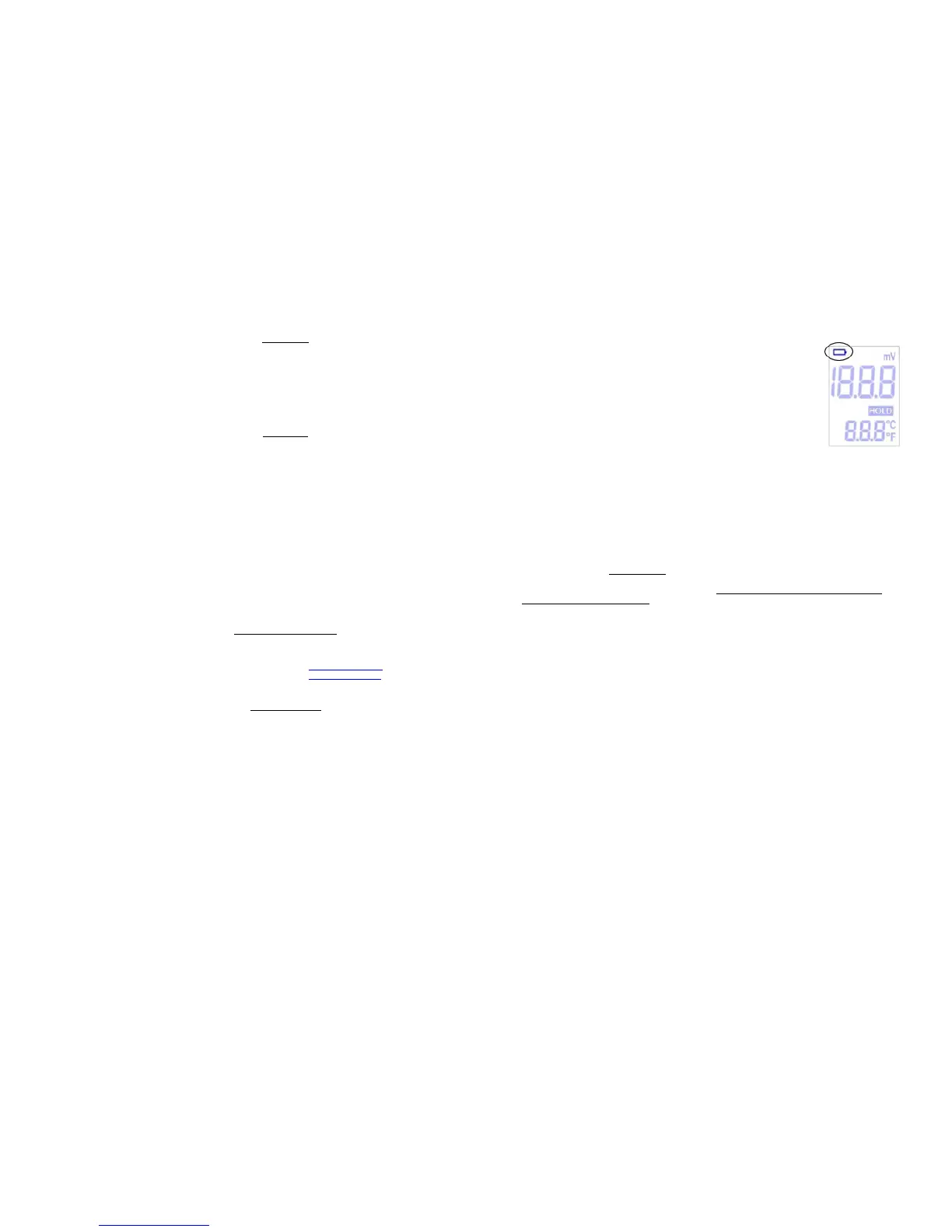

Display: LCD panel

Housing: Waterproof (submersible); floats

Power source: 3 x 1.5V button cell batteries (included), model 357A

Dimensions: 18.5 x 3.4 x 3.4 cm (7.3 x 1.3 x 1.3 inches)

Weight: 95 grams (3.35 ounces)

Changing the batteries:

When the meter displays a flashing battery symbol, your batteries are getting

weak and should be replaced soon. To change the batteries:

1. Twist open the battery compartment on the top of the meter.

2. Remove the three batteries.

3. Insert new batteries in the direction as depicted inside the compartment.

The meter uses 357A batteries.

4. Close the battery compartment. Make sure it is tightly closed to retain

waterproofness.

NOTE: Do not reverse the polarity of the batteries. This will short circuit the meter.

Cleaning and sensor care:

1. Never touch the sensor!

2. To clean the unit, use a soft rag or towel. Wipe with water and a mild soap or rubbing alcohol.

3. To clean the sensor, rinse in distilled water or a 7 pH buffer solution. If cleaning with a 7 pH buffer

solution, lightly dab (touch) the sensor on a soft tissue. Never rub the sensor with a tissue or anything

else, as this may scratch the glass.

4. If it is found that the glass sensor is scratched, it needs to be replaced.

5. If the sensor is dried up (or the gel within it), you can attempt to re-moisten the sensor by keeping it in

a 7.0 pH solution for at least two hours

. If the meter still does not function properly or accuracy is not at

optimum performance, the sensor may be irreparably damaged and must be replaced.

6. For best results, clean the sensor after each use, especially if used in very low or very high pH

liquids, or liquids other than water.

7. PROBE STORAGE: Storing the probe in a 4 pH KCl buffer solution is preferred (the meter is shipped

with this solution in the cap). It is okay to rinse the probe in distilled water, but never store the probe in

distilled water. Storing the probe in a higher pH buffer solution will not damage it.

Sensor Replacement:

If your sensor has been damaged, you can purchase a new one without having to purchase a new

meter. To replace the sensor:

1. Remove the sensor gasket ring by twisting it counter-clockwise.

2. Gently pull the sensor off the unit.

3. Gently insert the new sensor into the unit. Be sure to align the grooves properly. Never force the

sensor into the unit!

4. Make sure the rubber ring is properly positioned on the sensor.

5. Screw the gasket ring back onto the unit by twisting it clockwise. Tighten.

Sponge Care:

1. Never add distilled or tap water to the sponge/cotton ball, as mildew or mold may form.

2. Rewet with HM Digital’s bottling solution or a professionally made KCl solution with bactericide.

1 6

Loading...

Loading...