WV4262B POWERED DAMPER WATER HEATER CONTROLS

9 69-2496—03

TROUBLESHOOTING

Troubleshooting with LED

Indicator Assistance

1. Observe LED indicator on control; check and

repair the system as noted in Table 5. Error flash

codes are displayed with a 3 second pause

before repeating.

2. After LED flash code analysis and appliance

repair are complete, turn system switch to ON

and perform lighting procedure.

3. Observe the ignition sequence, comparing it to

the Sequence of Operations shown in Table 4.

Allow the new ignition sequence to proceed until

appliance lights or an abnormal or unexpected

event is observed.

4. If an unexpected event is observed, use the

Troubleshooting Guide, Fig. 8.

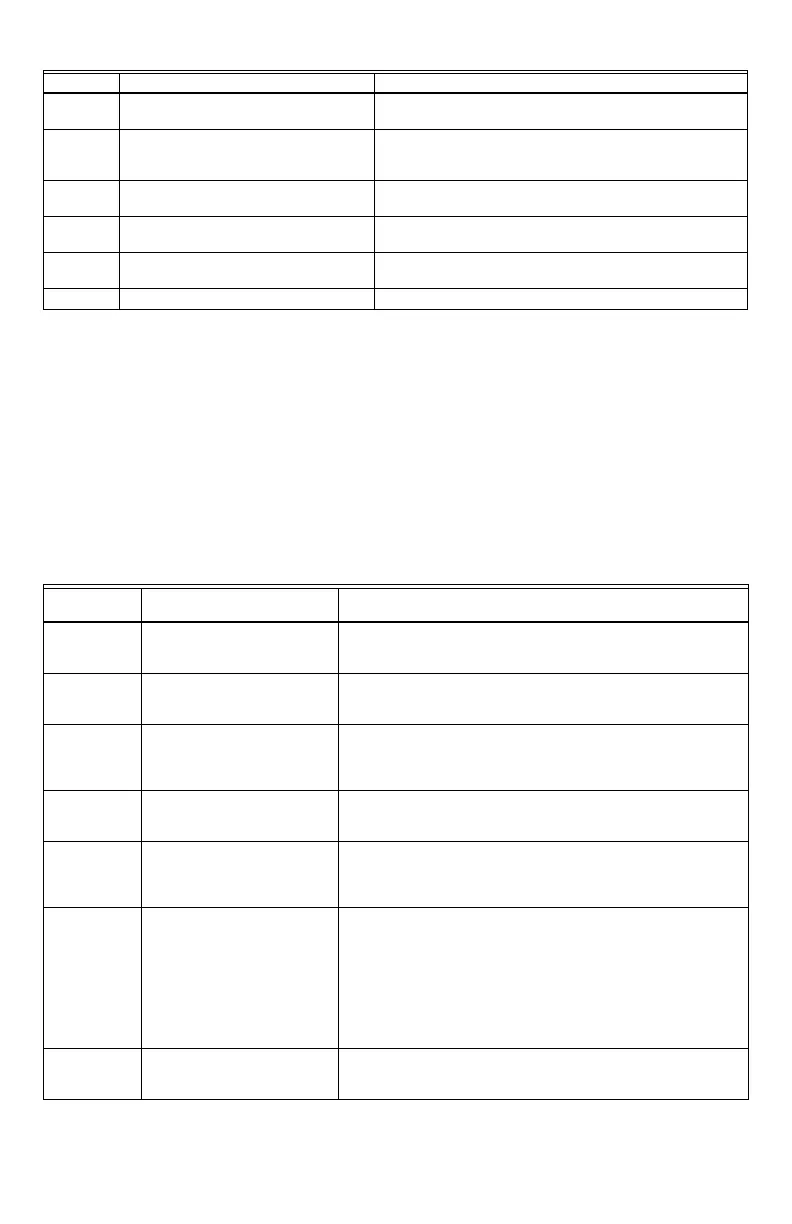

Table 5. Troubleshooting with the LED.

7 Energize main gas valve The main valve is energized (when flame is proved above

the “RUN” level).

8 Wait 3 seconds to stabilize flame Flame and Pressure Switch signals are ignored for 3

seconds after the main valve is energized (Flame

Stabilization Period).

9 Temperature reaches setpoint The demand for heat is satisfied (temperature reaches set

point).

10 De-energize the main and pilot gas

valves

The gas valves are de-energized.

11 Monitor Flame Flame is monitored until flame signal drops below Flame

Lost level.

12 De-energize damper motor The damper motor is de-energized.

Sequence Mode Description

Green LED

Status Indicates Check/Repair

Short flash

once every

four seconds

Idle (no call for heat and no

faults)

Not Applicable.

“Heartbeat”,

alternates

bright/dim

Call For Heat (no faults) Not Applicable

Short flash

once per

second

(Idle mode)

Low Flame Signal on last call

for heat

• Check spark/flame sense rod for build up of silicone-dioxide.

• Check spark/flame sense wire insulation.

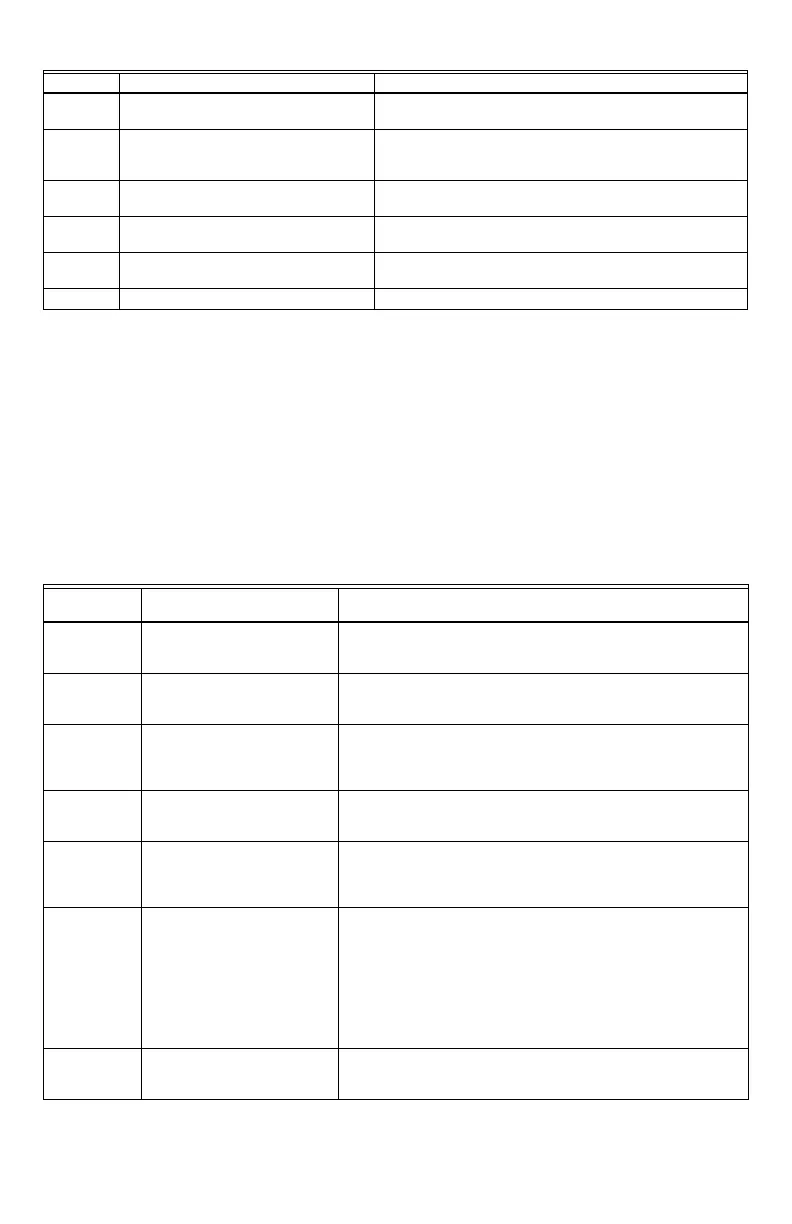

Two Flash,

three second

pause

Damper End Switch Failed

Closed

• Check damper end switch for welded contacts and shorted

wiring.

Three Flash,

three second

pause

TCO or Damper End Switch

Failed Open

• Check damper end switch for contact closure.

• Check wiring to damper end switch.

• Check damper motor is opening damper.

• Check damper for blockage.

Four Flash,

three second

pause

ECO Limit Lockout (water

temperature in excess of TCO)

• The control enters permanent lockout after three ECO events.

• Control can be reset by turning the Setpoint knob to its

minimum setting for at least 30 seconds, then returning the

Setpoint knob to the desired temp.

• ECO Limit should not be reached under normal operating

conditions. Check installation to insure all manufacturer

recommendations were followed.

• Reduce the setpoint temperature to keep max. water

temperature further away from ECO trip point.

Five Flash,

three second

pause

Flame Out Of Sequence • Check for pilot flame.

• Replace control if pilot flame is present when gas valve

should be off.

Loading...

Loading...