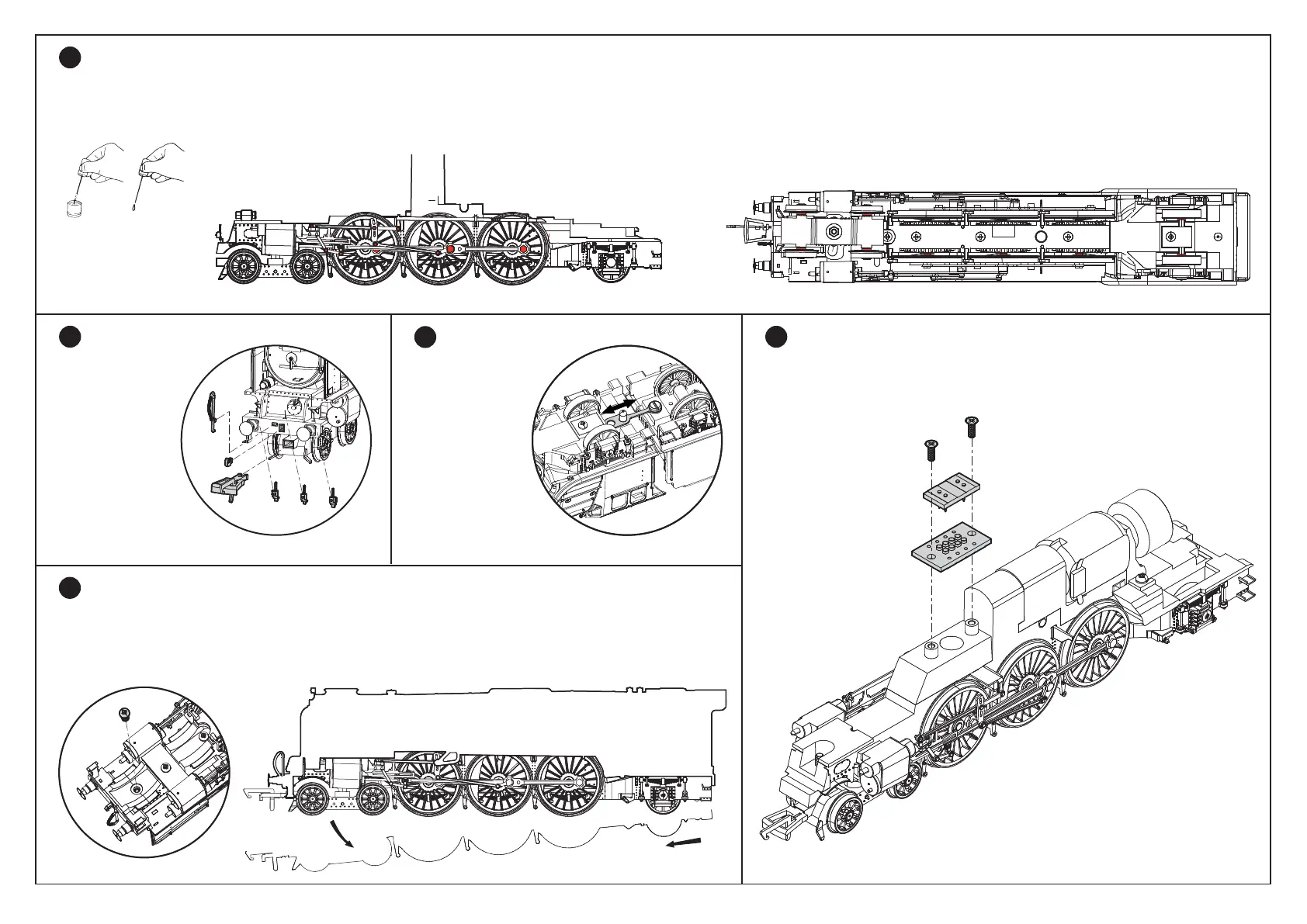

Body Removal

4

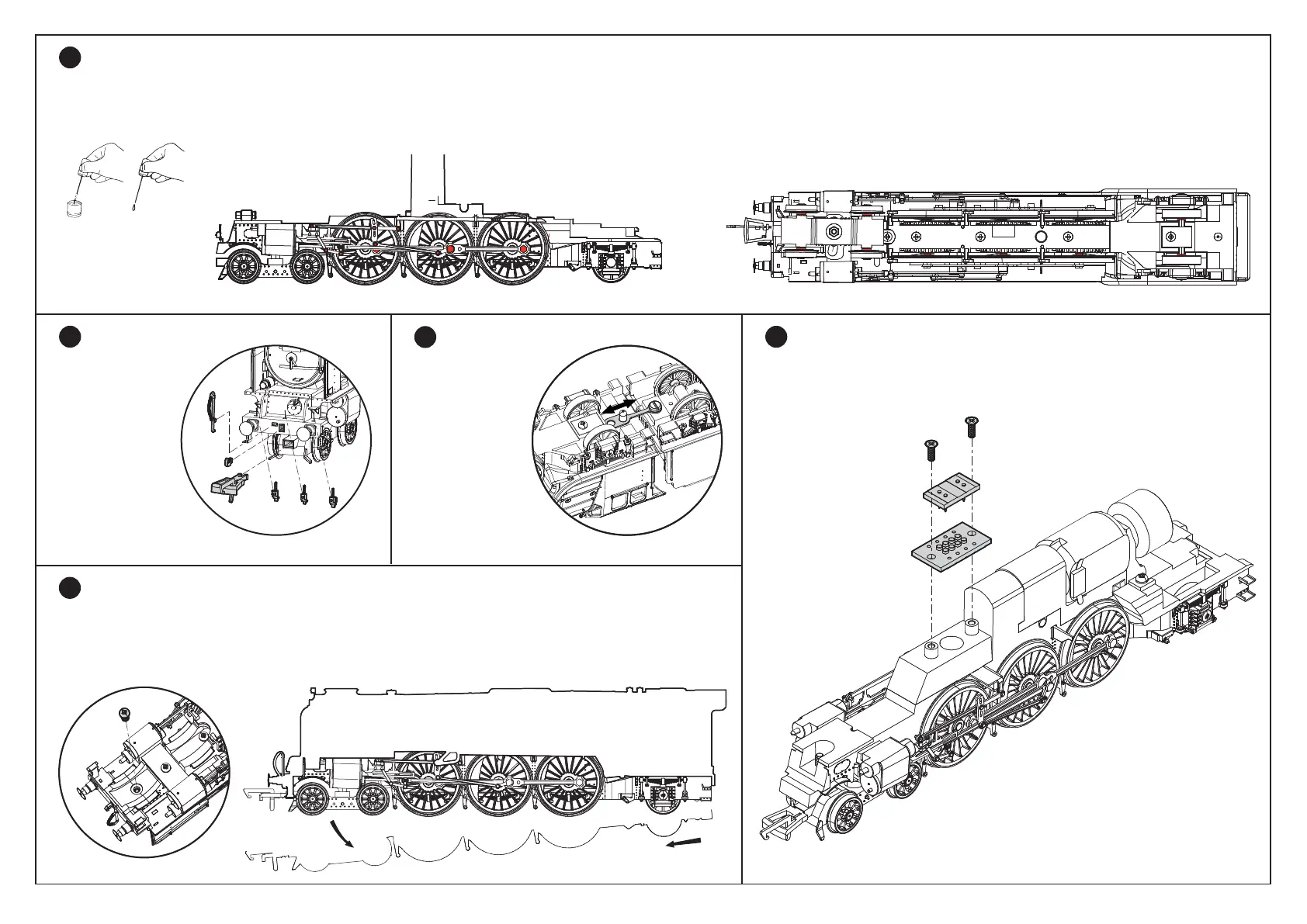

Lubrication

1

Fig.1

IMPORTANT – Only apply small single drops of light machine oil to the places indicated in red in Figs 2 and 3. This is best achieved by making a simple oil ‘dropper’ as illustrated in Fig.1. Insert a straightened paper clip into a cork and use a

bottle cap as a container for the oil. A small drop of oil can then be picked up by the dropper and applied in exactly the right place. Immediately wipe off any excess oil, especially from the locomotive body. Only lubricate moving parts.

Carefully fit the

detailed parts into

their location points

(see Figs 4)

Some of these

accessories should

only be fitted for use

on static displays.

Accessories

2

DCC Ready

If your locomotive is not pre-fitted with

a decoder, please see Fig.8 for location

of DCC socket.

5

Turn the locomotive upside down and remove Chassis/Body assembly screw (Fig. 6), then carefully turn locomotive

the right way up and drop the chassis down at the front. Move forward to disengage the chassis from the rear of the

body as shown in Fig.7.

Fig.4 Fig.5

Fig.7Fig.6

Fig.8

3

2

Apply one drop of oil to each of the valve gear and connecting rod

pivot points indicated in red in Fig.2, on both sides of the locomotive.

Fig.2

Fig.3

Apply one drop of oil to each of the axle bearings indicated in red in

Fig.3, on both sides of the locomotive.

Close coupling

3

2

1

To create a closer

coupling for display

purposes connect

the tender to the

locomotive by

utilising the closer

of the two holes

on the drawbar as

shown in Fig.5.

Loading...

Loading...