The fuser power supply has three main components:

● Fuser sleeve. A high-frequency current flows through an induction heating coil in the

fuser sleeve, causing the metal sleeve to heat.

● Thermistors. Two thermistors are in the fuser sleeve: one in the center, and the other at

the end. Each thermistor monitors the temperature in the fuser sleeve.

● Thermoswitch. The thermoswitch is located at the bottom center of the fuser sleeve.

When the fuser is overheating, the switch opens, and power to the induction heating coil

is shut off.

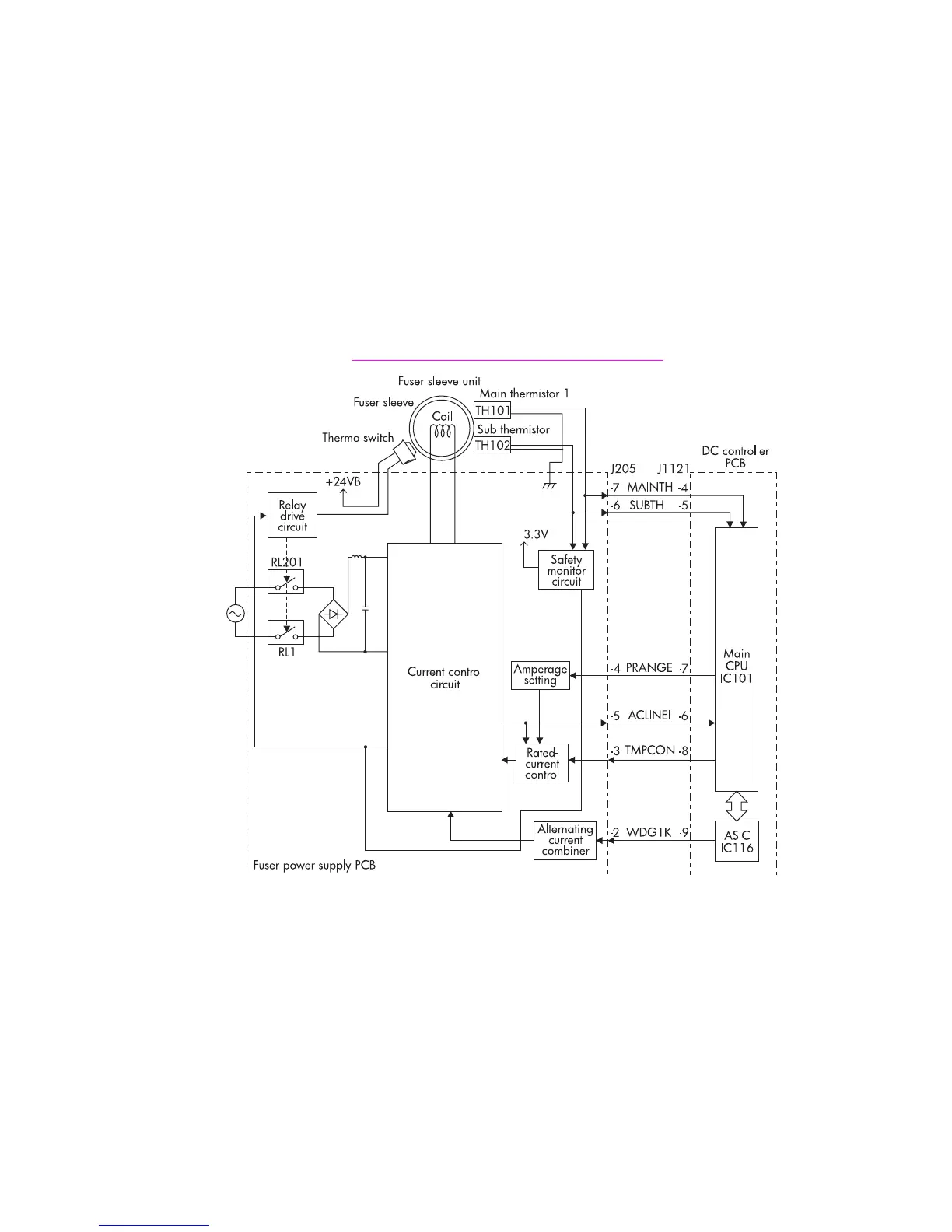

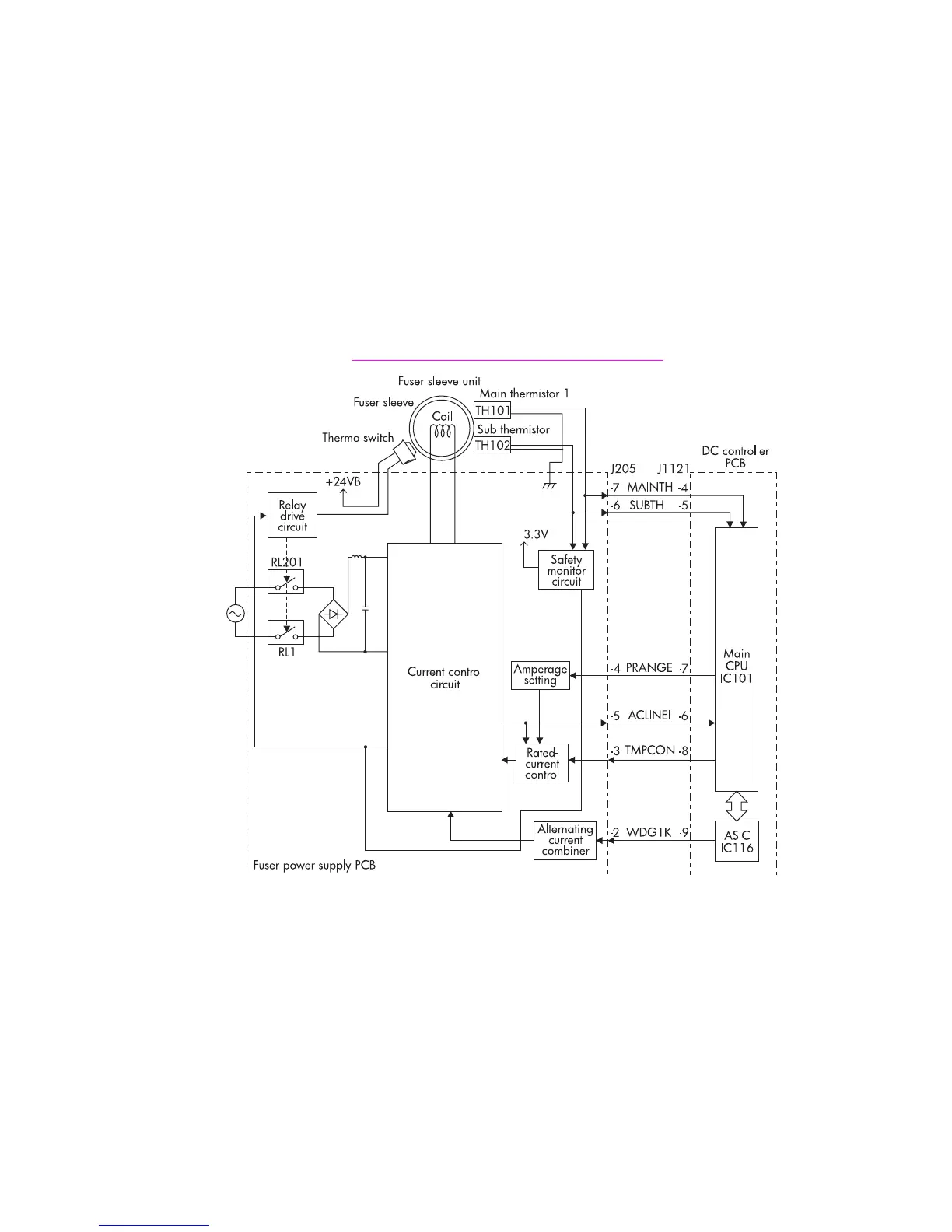

Heater temperature control

The heater temperature control detects the surface temperature of the fuser sleeve and

controls the current flowing to the induction heating coil. The heater temperature control

circuit is shown in

Figure 5-6. Heater temperature control circuit.

Figure 5-6.

Heater temperature control circuit

The two thermistors that are attached to the fuser sleeve (TH101 and TH102) detect the

surface temperature of the fuser sleeve. The main thermistor (TH101) controls the fuser

temperature, and the sub thermistor (TH102) detects overheating at the end of the fuser

sleeve. When the surface temperature of the fuser sleeve increases, resistance of the two

thermistors is reduced, and the voltage of the main thermistor detection signal (MAINTH)

and the sub thermistor detection signal (SUBTH) drops.

The main CPU (IC101) on the DC controller monitors the voltage of the MAINTH and

SUBTH signals. The CPU sends the fuser temperature control signal (TMPCON) according

to the voltage level.

136 Chapter 5 Theory of operation ENWW

Loading...

Loading...