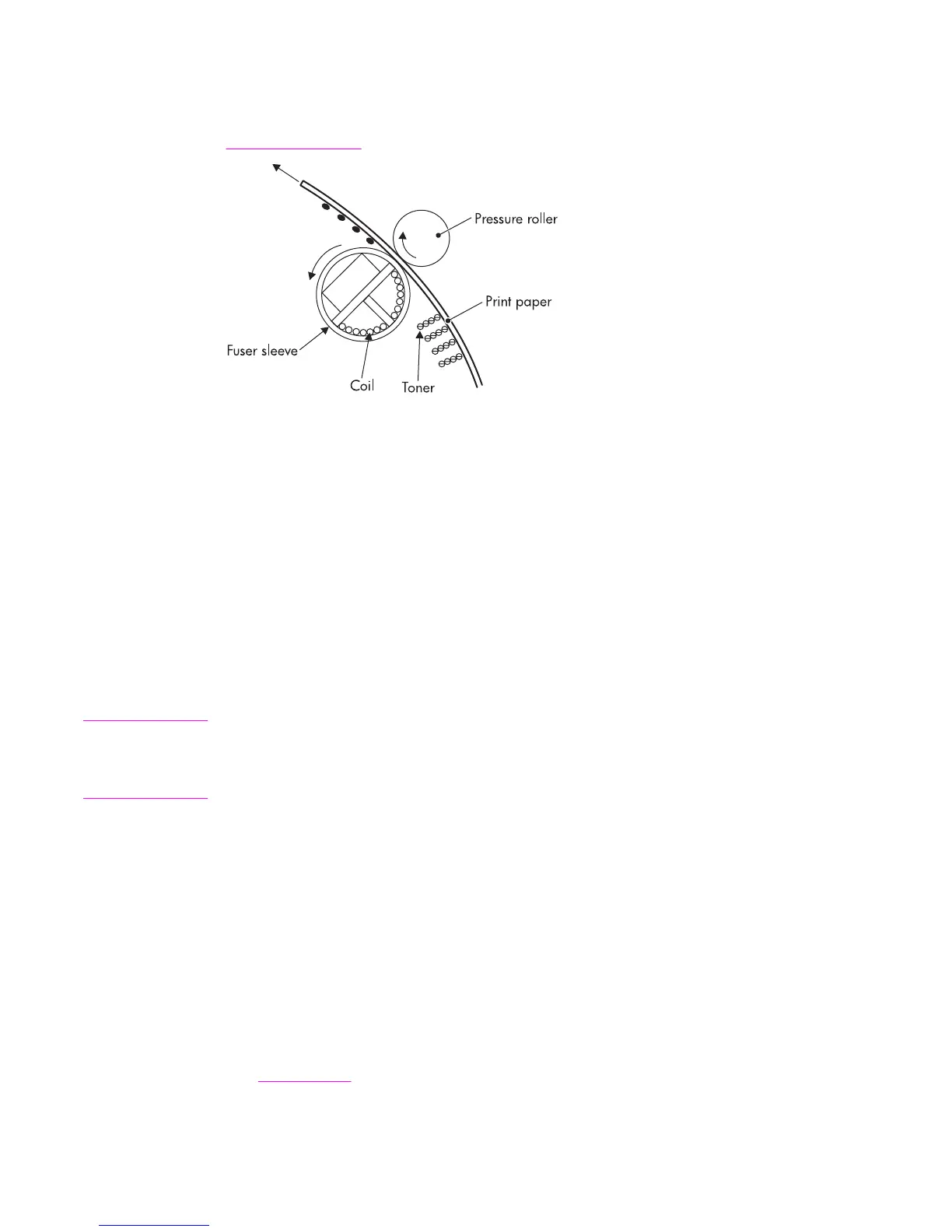

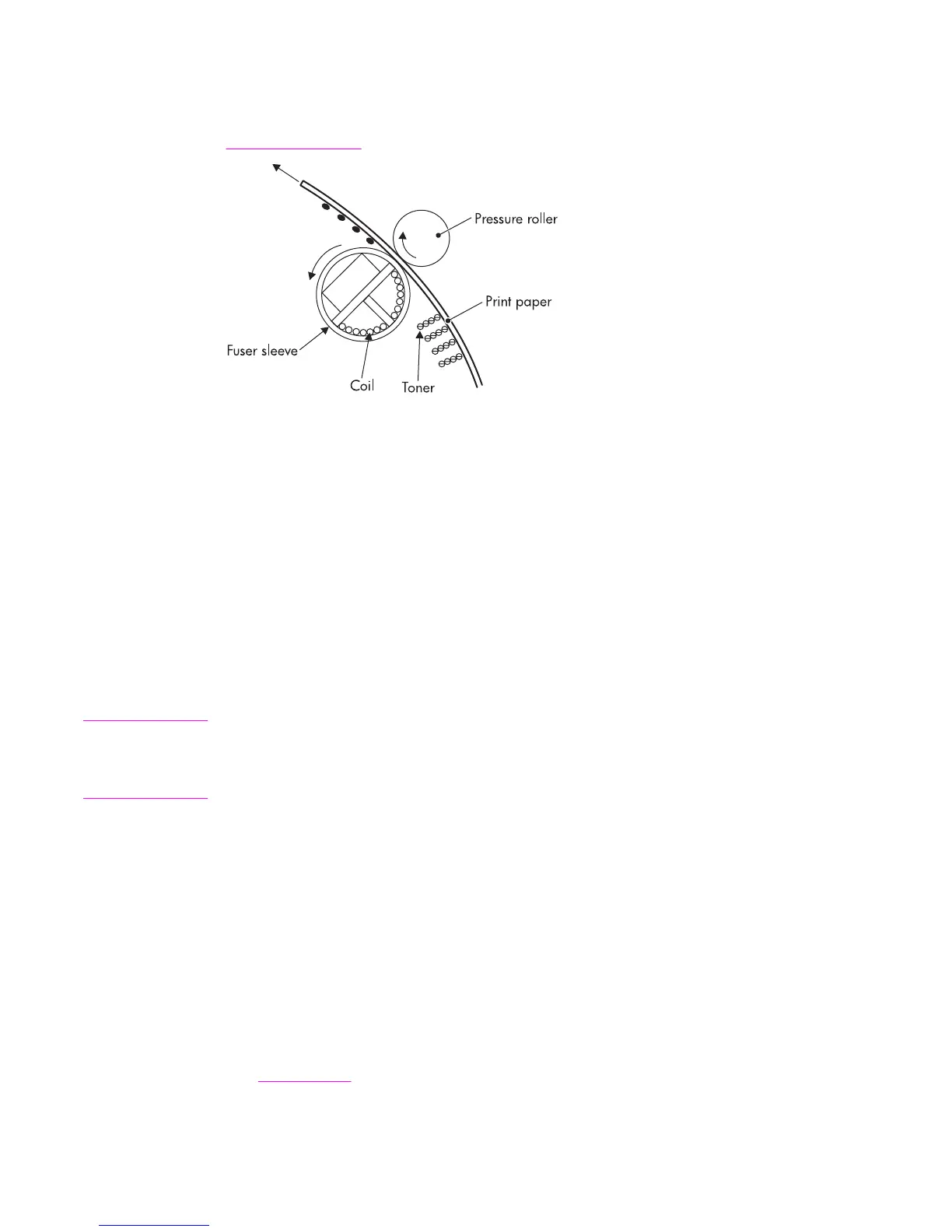

Step 9: Fusing

This printer uses the induction heating method to fuse the toner to the paper. This method

uses quick fuser heating, resulting in shortened wait time and reduced power consumption.

Figure 5-26. Fusing illustrates this step.

Figure 5-26.

Fusing

Fuser motor speed control

The fuser motor speed control for HP Color LaserJet 5550 models is explained in this section.

The HP Color LaserJet 5550 printer controls the motor speed in the same way the HP Color

LaserJet 5500 models does, except the HP Color LaserJet 5550 printer has two fixing paper

sensors: PS81 and PS82—to control the warp of specific types of thick paper.

There are two fixing paper detection flags, one for the PS81, and another for the PS82.

These flags shield their respective sensors. The sensors enable the DC controller to monitor

the warp of paper more closely than the HP Color LaserJet 5500 models can.

Thick paper is fed, the DC controller speeds up the fixing motor earlier than it does when a

normal paper is fed. This ensures minimal warping and prevents image distortion that can be

caused by paper thickness.

Note

The specific thick paper refers to the paper specified for the print mode, Thick Paper 2. Thick

paper is firmer than normal paper. The image can be distorted during transfer if the paper is

heavily warped and is pushed back toward the ETB. This is especially true of thick paper

with a high basic weight (grammage) that needs to have its warp diminished.

Cleaning block

The fifth and final part of the image formation process is the cleaning block, in which the ETB

and the photosensitive drums are cleaned, preparing them for the next print. The next

section provides more information about printer calibration and cleaning. This block consists

of two steps:

● ETB cleaning

● photosensitive drum cleaning

Step 10: ETB cleaning

See ETB cleaning for a complete discussion of ETB cleaning.

160 Chapter 5 Theory of operation ENWW

Loading...

Loading...