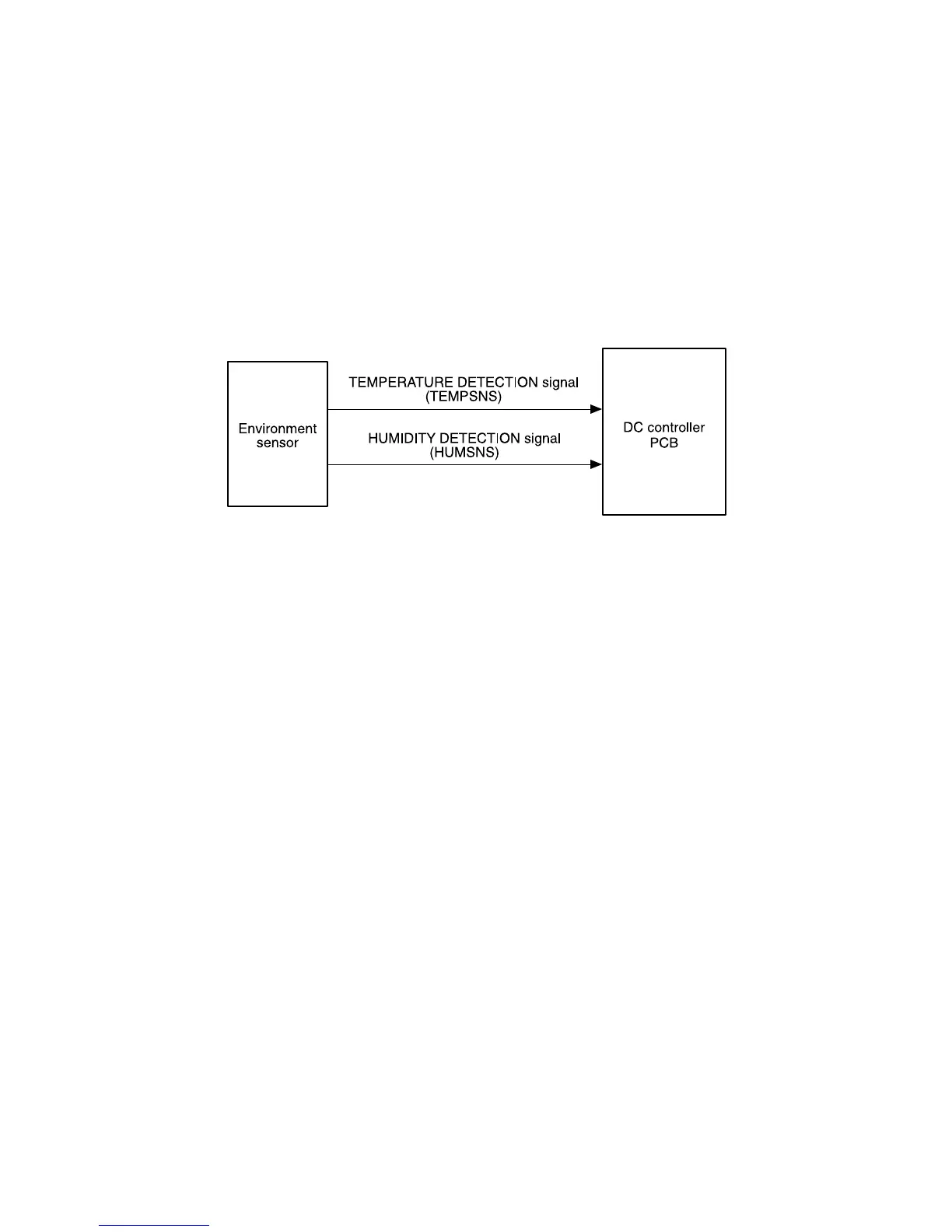

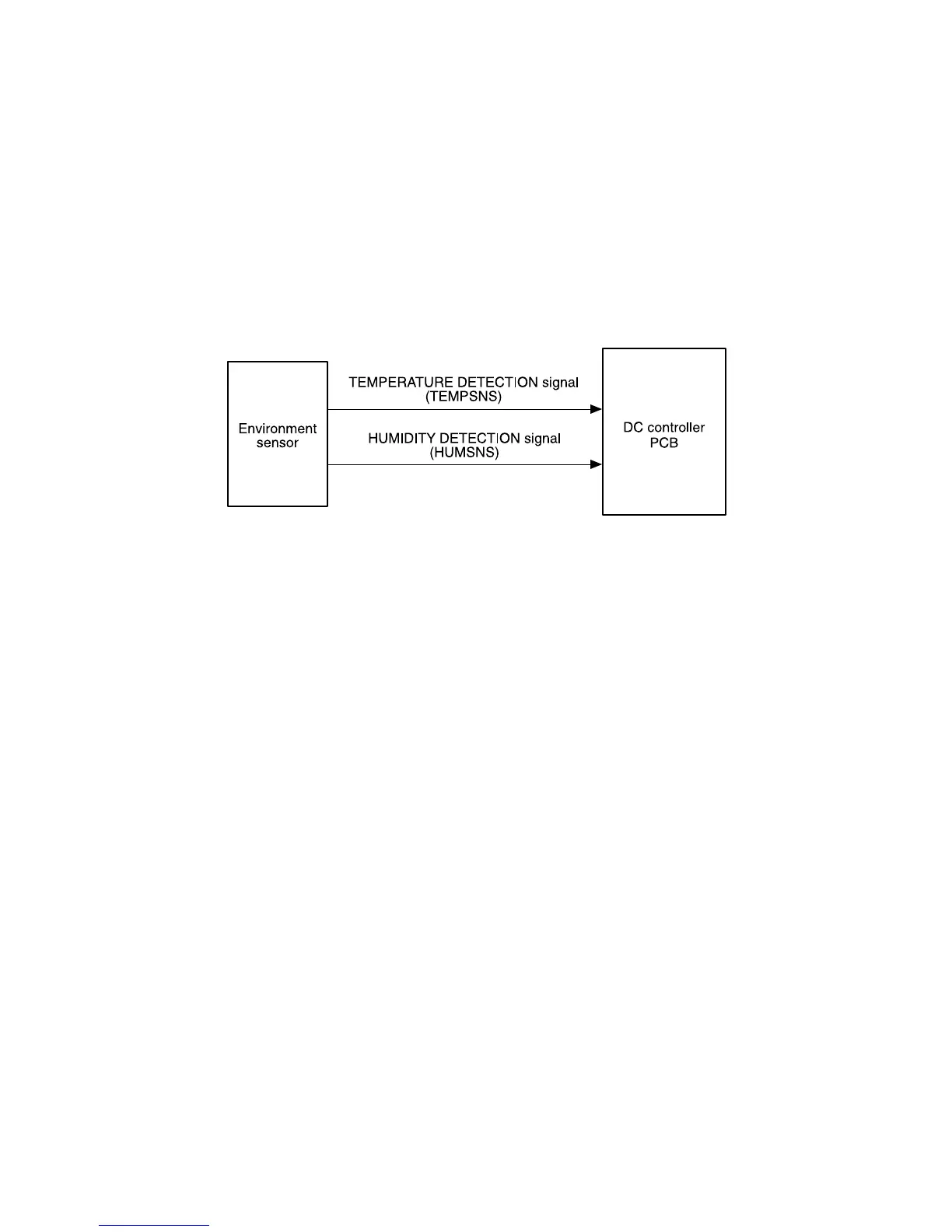

The DC controller monitors the environmental conditions of the printer based on these two

signals.

The DC controller controls the following biases to prevent image defects when it detects an

environmental change.

● Developing bias

● Primary transfer bias

● Secondary transfer bias

If the environment sensor detects a temperature below -30ºC (-22ºF) or over 80ºC (176ºF),

the DC controller determines this is an "environment sensor abnormality" and sends an error

message to the formatter.

If the environment sensor detects a temperature below 7ºC (44.6ºF), the printer will not

perform a calibration cycle.

Image density calibration control (DMAX)

This control stabilizes image density by calibrating the values of the developing bias

whenever one of the following events occurs:

● when the printer is turned on

● when a print cartridge is replaced

● after a set number of pages have printed

● when the formatter sends an operation command

Image density calibration consists of three steps:

1. The DC controller forms density patterns for each color on the ETB using varying levels

of developing bias.

2. The color registration detection unit measures the image density of the density patterns

formed on the ETB.

3. The DC controller uses the density measurements to adjust the developing bias to

obtain proper image density.

Image halftone calibration control (DHALF)

This control measures halftone density output from the formatter and returns the

measurements to the formatter so it can perform halftone calibration. Image density

calibration must always be performed prior to image halftone calibration.

Image halftone calibration control consists of three steps:

1. Using the optimum developing bias determined during image density calibration, the DC

controller forms density patterns on the photosensitive drum in each color cartridge.

ENWW Image formation system 167

Loading...

Loading...