2. The test chart is scanned and color-measured using the embedded spectrophotometer. If the scan

cannot be completed successfully, a message is displayed by the Internal Print Server; see

Color

calibration fails on page 257.

3. From the measurements made by the spectrophotometer, the printer calculates the necessary

correction tables to apply to your print jobs, for consistent color printing on that substrate type.

Calibration should be done in any of the following circumstances:

●

Whenever a new substrate type is introduced that has not yet been calibrated.

●

Whenever you notice excessive color differences between prints. Such color differences can be caused

by aging and wear of the printheads, installing new printheads, changes in substrate characteristics

between one roll and another, changing environmental conditions, and so on.

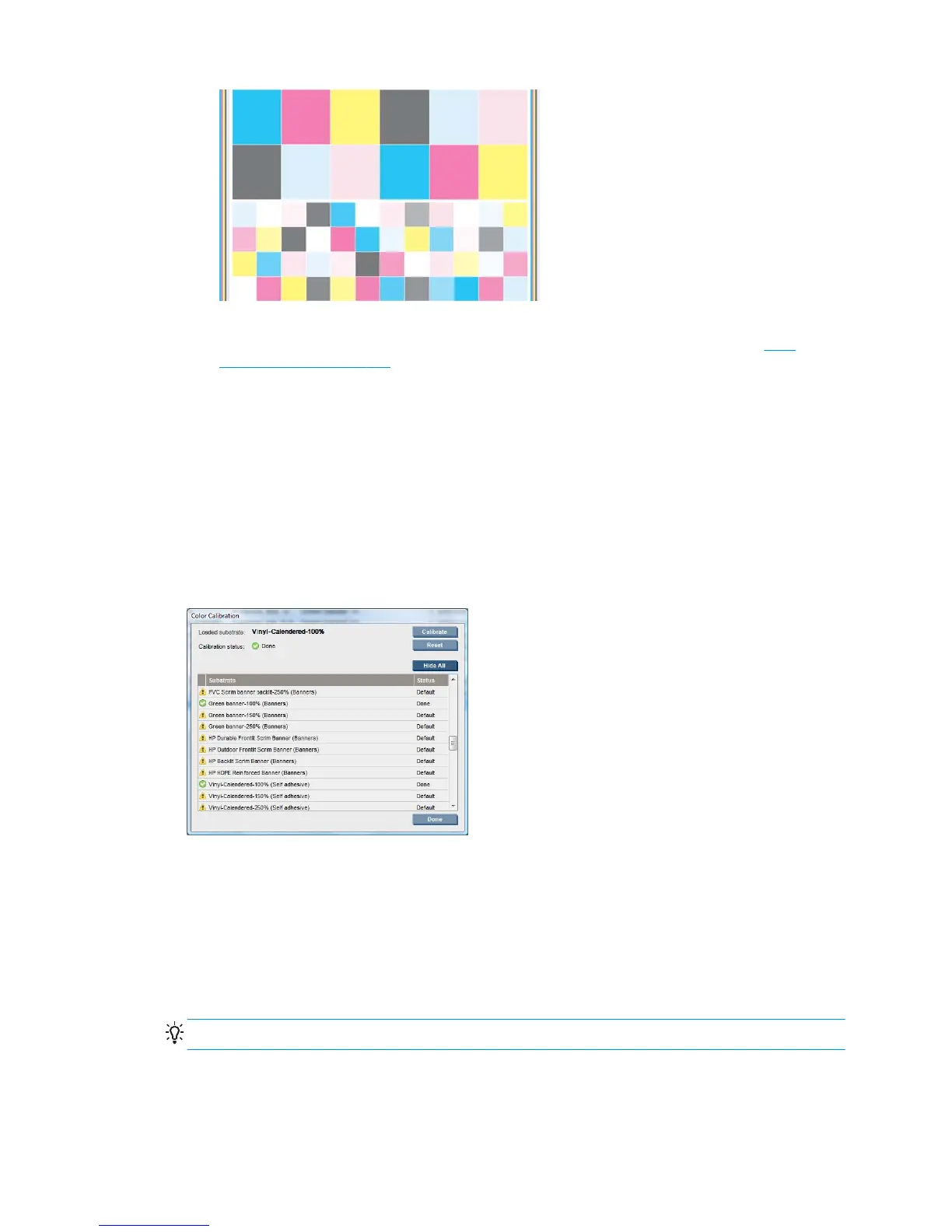

You can check the color calibration status of your substrates with the Internal Print Server: select Substrate

> Color calibration > Show all.

●

Default status indicates that this substrate has never been calibrated. In this case, the factory-default

color tables will be applied to print jobs since there is no reference state defined.

●

Done status indicates that a color calibration has been performed successfully on this substrate,

reference state defined.

Color calibration is based on the color measurement of printed color patches, using the embedded

spectrophotometer. Some characteristics of substrates, such as surface roughness or transparency, may

make reflective color measurement of some substrate types very inaccurate. Color calibration of these

substrates may fail or produce unacceptable printing results.

TIP: If color calibration fails at the first attempt, it is worth trying again.

To restore the factory-default calibrations and delete substrate color references (reference state) a color

calibration reset must be done. In the Internal Print Server, select Substrate > Color calibration > Reset.

ENWW Color calibration 105

Loading...

Loading...