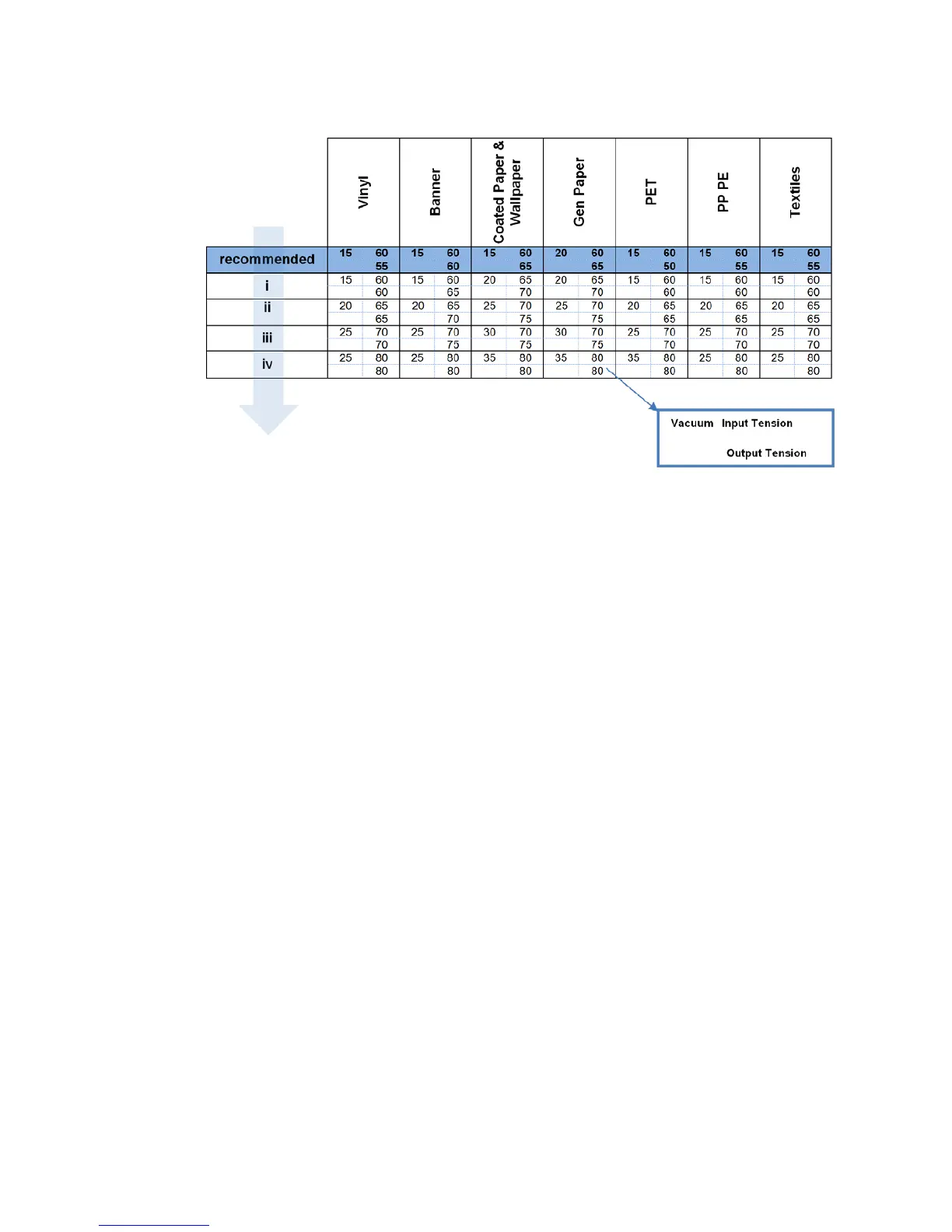

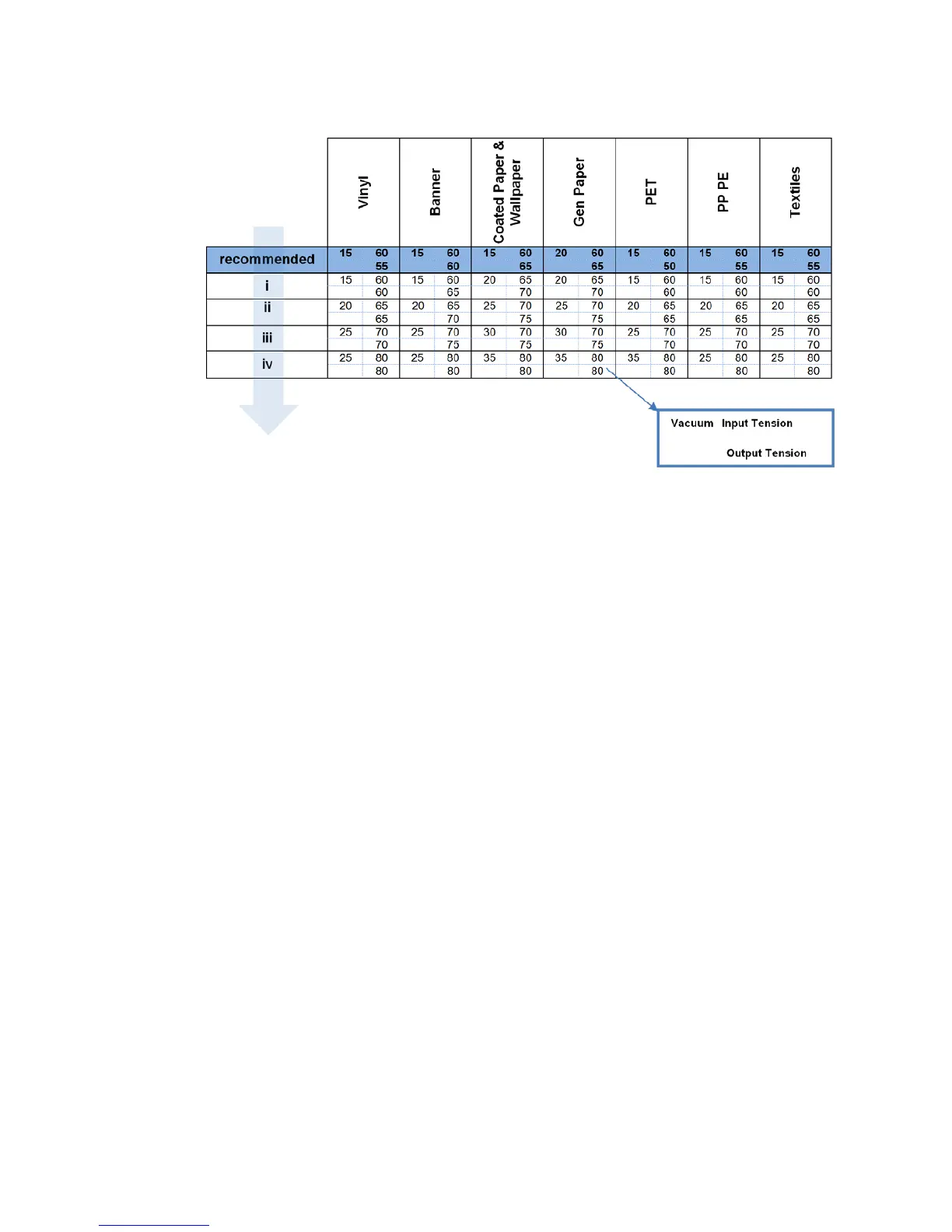

2. Start with the recommended configuration and increase vacuum and tensions step by step (i to iv),

following the table below.

There are wrinkles and ink smears on the substrate

Wrinkles in the substrate indicate that the substrate settings that control the substrate shape are not

optimized. This can cause various printing defects.

●

Colored bands in area fills in the vicinity of the wrinkles

●

Ink smears if the printhead touches the substrate

●

Cockle

●

A substrate crash if the printhead's movement over the substrate is impeded

There are various reasons why wrinkles and other consequent effects could appear while printing:

●

Incorrect loading of the substrate

●

Incorrect routing of the substrate through the printer

●

Incorrectly positioned edge holders

●

Drying and curing temperatures too high for the substrate

●

Differential expansion of the substrate due to variations in temperature

●

Insufficient tension settings

●

Non-uniform tension across the substrate when loading

If your prints suffer from any of the defects caused by wrinkles, here are some suggestions.

1. Check that the substrate you are using is the same type as the one you have selected in the Internal

Print Server.

2. Check that you are using the generic substrate preset for the substrate category. The use of incorrect

values may cause incorrect substrate behavior.

3. Check that there is no telescoping of the input roll.

224 Chapter 9 Troubleshoot substrate issues ENWW

Loading...

Loading...