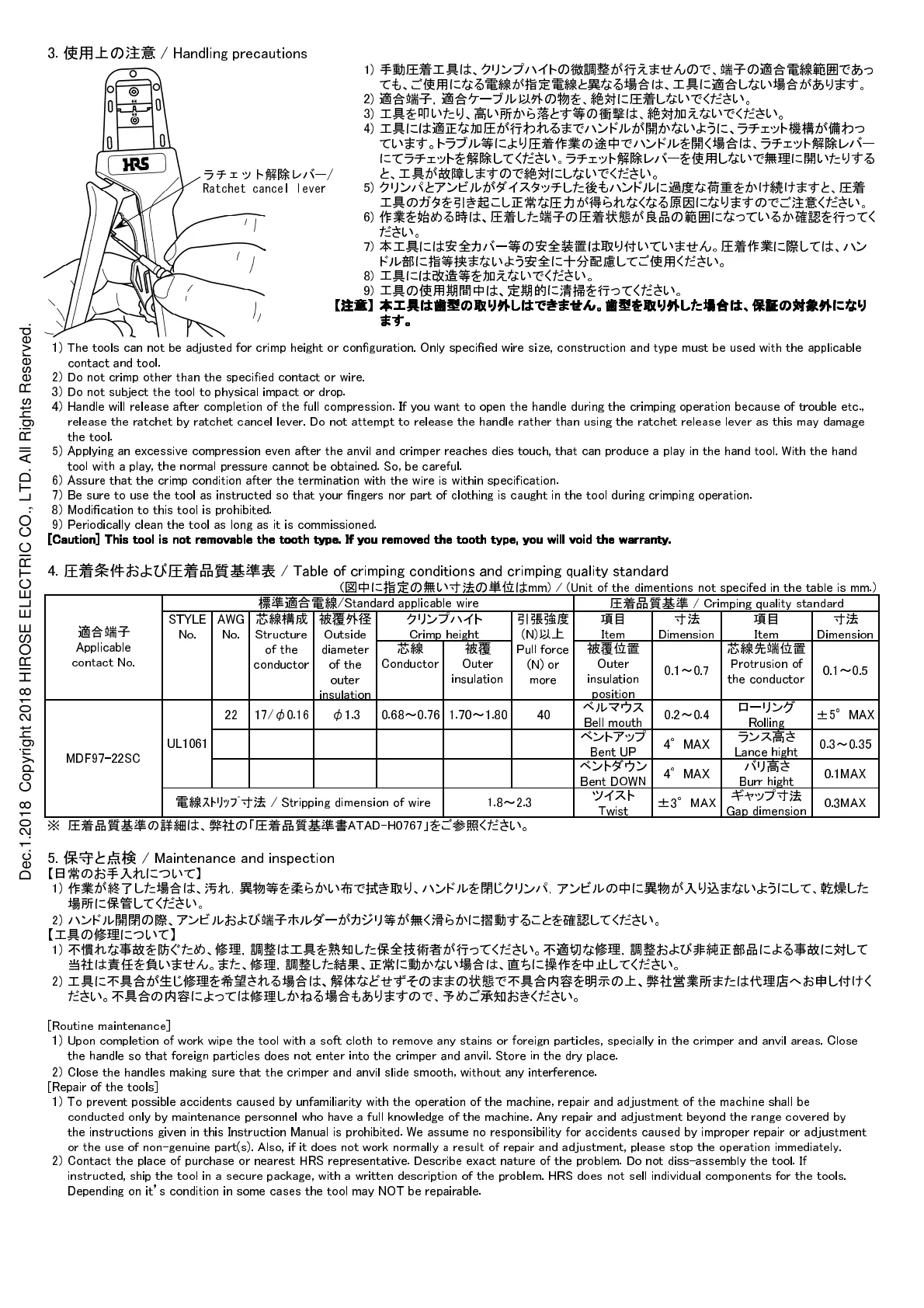

3. 使用上の注意 / Handling precautions

1)

4)

5)

6)

7)

【注意】

【注意】【注意】

【注意】

1)

4)

5)

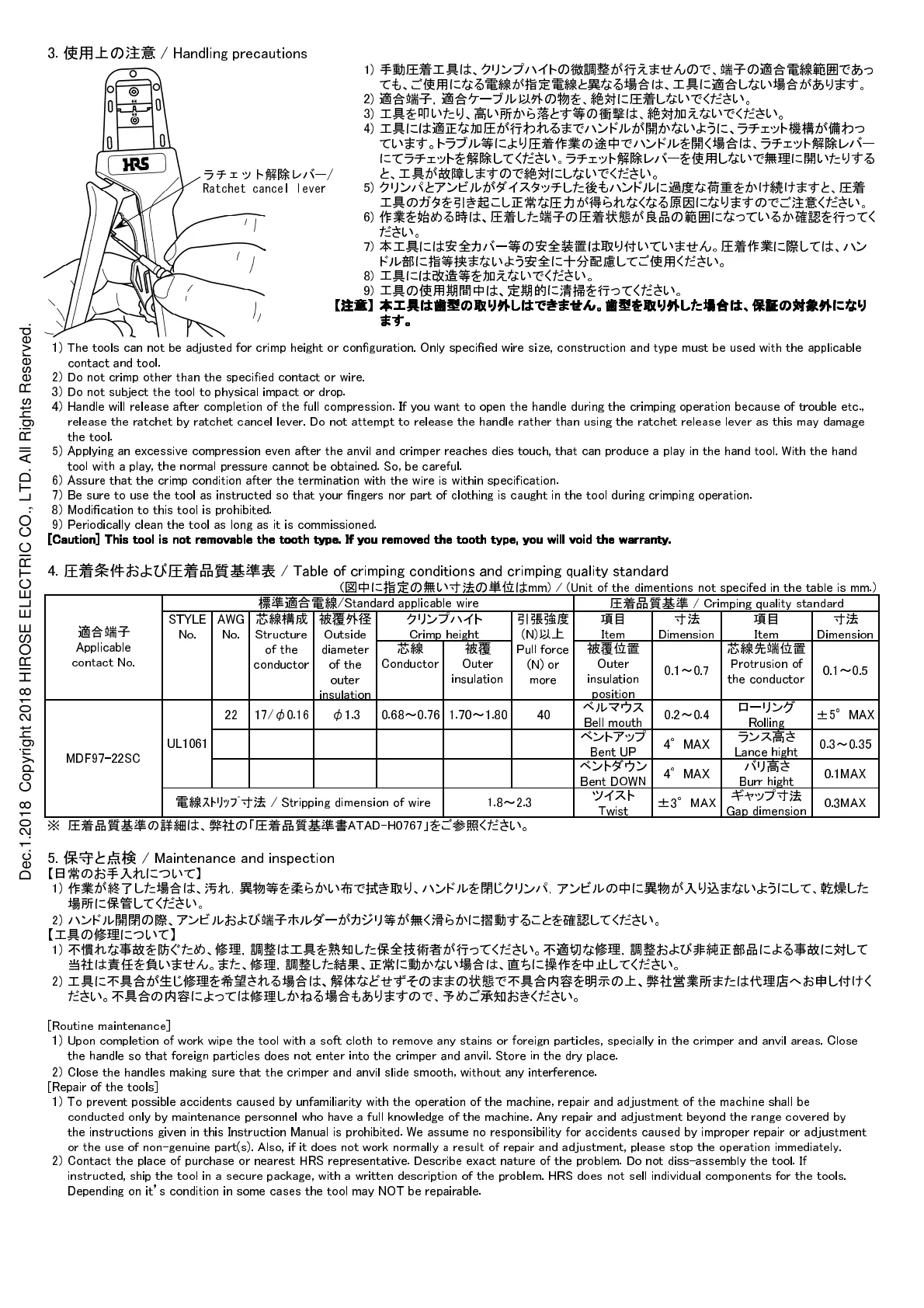

4. 圧着条件および圧着品質基準表 / Table of crimping conditions and crimping quality standard

(図中に指定の無い寸法の単位はmm) / (Unit of the dimentions not specifed in the table is mm.)

項目

寸法

項目

寸法

芯線

Conductor

被覆

Outer

insulation

被覆位置

Outer

insulation

0.1~0.7

芯線先端位置

Protrusion of

the conductor

0.1~0.5

22 17/φ0.16 φ1.3 0.68~0.76 1.70~1.80 40

ベルマウス

0.2~0.4

ローリング

±5°MAX

ベントアップ

4°MAX

ランス高さ

0.3~0.35

ベントダウン

4°MAX

バリ高さ

0.1MAX

ツイスト

±3°MAX

ギャップ寸法

0.3MAX

圧着品質基準の詳細は、弊社の「圧着品質基準書ATAD-H0767」をご参照ください。

5. 保守と点検 / Maintenance and inspection

1)

1)

2)

1)

1)

2)

Applying an excessive compression even after the anvil and crimper reaches dies touch, that can produce a play in the hand tool. With the hand

tool with a play, the normal pressure cannot be obtained. So, be careful.

Modification to this tool is prohibited.

Periodically clean the tool as long as it is commissioned.

MDF97-22SC

標準適合電線/Standard applicable wire

Contact the place of purchase or nearest HRS representative. Describe exact nature of the problem. Do not diss-assembly the tool. If

instructed, ship the tool in a secure package, with a written description of the problem. HRS does not sell individual components for the tools.

Depending on it’s condition in some cases the tool may NOT be repairable.

作業が終了した場合は、汚れ,異物等を柔らかい布で拭き取り、ハンドルを閉じクリンパ,アンビルの中に異物が入り込まないようにして、乾燥した

場所に保管してください。

ハンドル開閉の際、アンビルおよび端子ホルダーがカジリ等が無く滑らかに摺動することを確認してください。

不慣れな事故を

防ぐ

た

め

、修理,

調整

は工具を

熟知

した保

全技術者

が

行

ってください。不適

切

な修理,

調整

および

非純

正

部

品による事故に

対

して

当社は

責任

を

負

いませ

ん

。また、修理,

調整

した

結果

、正常に動かない場合は、

直ち

に

操

作を中

止

してください。

UL1061

工具に不具合が

生

じ修理を

希望

される場合は、解

体

な

ど

せず

そ

のままの

状態

で不具合

内容

を

明示

の

上

、弊社

営

業所または

代

理

店へ

お

申

し

付け

く

ださい。不具合の

内容

によっては修理しか

ね

る場合

も

ありますので、

予め

ご

承知

おきください。

Upon completion of work wipe the tool with a soft cloth to remove any stains or foreign particles, specially in the crimper and anvil areas. Close

the handle so that foreign particles does not enter into the crimper and anvil. Store in the dry place.

電線

ストリップ

寸法 / Stripping dimension of wire 1.8~2.3

Assure that the crimp condition after the termination with the wire is within specification.

Be sure to use the tool as instructed so that your fingers nor part of clothing is caught in the tool during crimping operation.

芯線

構成

Structure

of the

conductor

[Caution] This tool is not removable the tooth type. If you removed the tooth type, you will void the warranty.

[Caution] This tool is not removable the tooth type. If you removed the tooth type, you will void the warranty.[Caution] This tool is not removable the tooth type. If you removed the tooth type, you will void the warranty.

[Caution] This tool is not removable the tooth type. If you removed the tooth type, you will void the warranty.

適合端子

Applicable

contact No.

ST

Y

LE

No.

圧着品質基準 / Crimping quality standard

本

工具には

安全

カバー等の

安全装

置は取り

付

いていませ

ん

。圧着作業に際しては、ハン

ドル

部

に指等

挟

まないよう

安全

に

十分配慮

してご

使用

ください。

The tools can not be ad

j

usted for crimp height or configuration. Only specified wire si

z

e, construction and type must be used with the applicable

contact and tool.

To prevent possible accidents caused by unfamiliarity with the operation of the machine, repair and ad

j

ustment of the machine shall be

conducted only by maintenance personnel who have a full knowledge of the machine. Any repair and ad

j

ustment beyond the range covered by

the instructions given in this Instruction Manual is prohibited. We assume no responsibility for accidents caused by improper repair or ad

j

ustment

or the use of non-genuine part(s). Also, if it does not work normally a result of repair and ad

j

ustment, please stop the operation immediately.

Close the handles making sure that the crimper and anvil slide smooth, without any interference.

手動圧着工具は、クリンプハイトの

微調整

が

行え

ませ

ん

ので、端子の適合電線

範囲

であっ

て

も

、ご

使用

になる電線が指定電線と異なる場合は、工具に適合しない場合があります。

適合端子,適合ケーブル

以外

の物を、

絶対

に圧着しないでください。

工具を

叩

いたり、高い所から

落

とす等の

衝撃

は、

絶対加え

ないでください。

工具には適正な

加

圧が

行

われるまでハンドルが開かないように、ラチェット機

構

が

備

わっ

ています。トラブル等により圧着作業の

途

中でハンドルを開く場合は、ラチェット解除

レ

バー

にてラチェットを解除してください。ラチェット解除

レ

バーを

使用

しないで無理に開いたりする

クリンプハイト

Crimp height

引

張強度

(N)

以上

Pull force

(N) or

more

Do not crimp other than the specified contact or wire.

Do not sub

j

ect the tool to physical impact or drop.

被覆

外径

Outside

diameter

of the

outer

AWG

No.

クリンパとアンビルがダイス

タ

ッチした後

も

ハンドルに

過度

な

荷重

をか

け続け

ますと、圧着

工具の

ガタ

を引き

起

こし正常な圧

力

が

得

られなくなる

原因

になりますのでご注意ください。

Handle will release after completion of the full compression. If you want to open the handle during the crimping operation because of trouble etc.,

release the ratchet by ratchet cancel lever. Do not attempt to release the handle rather than using the ratchet release lever as this may damage

工具には

改造

等を

加え

ないでください。

工具の

使用期間

中は、定

期的

に

清掃

を

行

ってください。

本工具は歯型の取り外しはできません。歯型を取り外した場合は、保証の対象外になり

本工具は歯型の取り外しはできません。歯型を取り外した場合は、保証の対象外になり本工具は歯型の取り外しはできません。歯型を取り外した場合は、保証の対象外になり

本工具は歯型の取り外しはできません。歯型を取り外した場合は、保証の対象外になり

ます。

ます。ます。

ます。

作業を

始め

る

時

は、圧着した端子の圧着

状態

が

良

品の

範囲

になっているか確認を

行

ってく

ださい。

ラチェット解除レバー/

Ratchet cancel lever

Dec.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Powered by TCPDF (www.tcpdf.org)

Loading...

Loading...