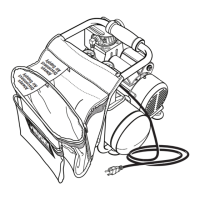

This document is the operator's manual for a Husky 6 Gallon Portable Air Compressor, model H1506F. It provides comprehensive instructions for safe operation, assembly, maintenance, and troubleshooting of the device.

Function Description

The Husky 6 Gallon Portable Air Compressor is designed to produce compressed air for various applications. It features an oil-free universal motor, which provides rotational force to operate the compressor pump. The pump, in turn, produces compressed air with a reciprocating piston contained within a cylinder. This compressed air is then stored in a cylindrical air tank. The compressor is equipped with a pressure switch that automatically controls its on/off cycling, stopping when the cut-off pressure in the tank is reached and restarting when the air pressure drops below the cut-in pressure. A manual on/off switch allows the user to turn the compressor on or off, but the pressure switch will not automatically start and control the compressor unless the manual switch is in the ON position. A safety valve is integrated to automatically release air if the air receiver pressure exceeds a predetermined limit, preventing over-pressurization. The compressor also includes a thermal overload switch that automatically shuts off the compressor if the electric motor's temperature exceeds a predetermined limit.

The compressed air can be regulated for output pressure using a pressure regulator knob, which adjusts the amount of air delivered through the hose. The current line pressure is displayed on a regulator pressure gauge, while a tank pressure gauge indicates the pressure of the air in the tank. The compressor is intended for operating some air-powered tools and for inflating tires, air beds, sports equipment, and similar items. It is crucial to note that this compressor/pump is not equipped and should not be used to supply breathing quality air, as additional equipment would be necessary to properly filter and purify the air to meet minimal specifications for Grade D breathing air.

Usage Features

The air compressor is designed for ease of operation and portability. It comes with a built-in cord wrap for convenient storage and movement. The accessory kit includes a quick coupler, a 1/4 inch NPT male connector fitting, a 1/4 inch NPT female connector fitting, an inflation needle with adapter, an air chuck, two inflation nozzles, and a 25 ft. coil hose, allowing for immediate use with various air tools and inflation tasks.

Before initial use, the pump requires a break-in period of 10 minutes, during which the drain valve should be completely open and the pressure regulator knob turned fully clockwise to open the air flow. After the break-in, the drain valve should be closed. When connecting the hose, seal thread tape should be applied to both ends of the coil hose to ensure a leak-free seal. The quick coupler is then attached to the open end of the hose. Users are warned not to attach an air chuck or other tool to the open end of the hose until start-up is complete.

To operate, the power switch must be in the OFF position and the compressor unplugged. The hose is attached to the compressor, and the appropriate male connector fitting is attached to the accessory or tool. The male connector is then inserted into the quick coupler. The regulator knob is rotated fully clockwise to open air flow and locked. After connecting the power cord, the switch is turned ON. The pressure regulator knob is then adjusted to the desired line pressure, increasing pressure by turning clockwise and decreasing it by turning counterclockwise. Users are advised to use the minimum amount of pressure necessary for their application to avoid rapid air drainage and frequent cycling. When finished, the tank should always be drained, and the unit unplugged. The compressor should never be left plugged in or running unattended.

For electrical safety, the compressor requires a 120-volt, 60 Hz, AC only power supply. It is equipped with a 3-prong grounding plug and requires a matching grounded outlet. The manual provides a chart for determining the minimum wire size for extension cords, emphasizing the use of heavy-gauge cords to prevent voltage drop and motor overheating. Outdoor use requires an extension cord marked "W-A" or "W."

Maintenance Features

Proper maintenance is essential for the longevity and safe operation of the air compressor. A critical daily maintenance task is draining moisture from the air tank to prevent corrosion. If the unit will not be used for a while, the drain valve should be left open to allow complete moisture drainage. Condensate is a polluting material and must be disposed of in compliance with local regulations. If the drain valve becomes clogged, all air pressure must be released, the valve removed and cleaned, then reinstalled.

The safety valve must be checked before each day of use by pulling its ring for three to five seconds to ensure it releases air and immediately stops when released. If air leaks after release or if the valve is stuck, the compressor must not be used until the safety valve has been replaced by an authorized service center. Users are strictly warned not to tamper with the safety valve.

The air compressor features permanently lubricated bearings, eliminating the need for further lubrication under normal operating conditions. For general cleaning, the exterior of the air compressor should be kept dry, clean, and free from oil and grease using a clean cloth. Users are advised against using brake fluids, gasoline, petroleum-based products, or strong solvents on plastic parts, as these can cause damage, weakening, or destruction of the plastic, potentially leading to serious personal injury. If the compressor is used in dusty environments or with materials like fiberglass, wallboard, spackling compounds, or plaster, it is extremely important to clean the tool using compressed air to prevent accelerated wear.

In case of any issues, a troubleshooting guide is provided to help identify and resolve common problems such as the compressor not running, motor hums, fuses blowing, thermal overload trips, air receiver pressure drops, excessive moisture in discharge air, continuous running, vibrations, or low air output. For service or repairs, the manual emphasizes that only qualified repair personnel should perform the work, using identical replacement parts. Users are instructed to contact an authorized service center for any repair needs.