This document is the operator's manual for the Husky 1.5 Gallon Portable Air Compressor, model H150PL. It provides comprehensive information regarding the compressor's function, technical specifications, usage, and maintenance.

The Husky H150PL is a portable air compressor designed for various air system applications, including operating light-duty air-powered tools and inflating items such as tires, air beds, and sports equipment. It is engineered and manufactured to Husky's high standard for dependability, ease of operation, and operator safety, promising years of rugged, trouble-free performance with proper care.

Function Description:

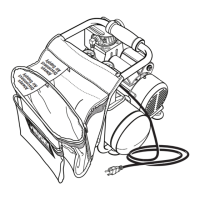

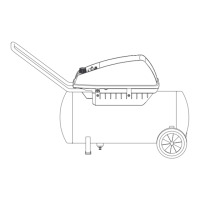

The air compressor's primary function is to produce compressed air for various applications. It utilizes an electric motor to drive a reciprocating piston pump, which compresses air and stores it in a 1.5-gallon air tank. The compressor features an automatic on/off cycling mechanism controlled by a pressure switch. It stops when the cut-off pressure in the tank is reached and restarts when the air pressure drops below the cut-in pressure. A pressure regulator knob allows users to adjust the outgoing air pressure to suit the specific requirements of the connected air tool or accessory. A pressure relief valve is incorporated as a safety feature, automatically releasing air if the tank pressure exceeds a preset maximum, preventing over-pressurization. The unit is designed for ease of use with a padded carrying handle for portability and a detachable tool bag for storing additional items.

Important Technical Specifications:

- Model: H150PL

- Running Horsepower: 3/4 HP

- Air Tank Capacity: 1.5 gallons

- Maximum Air Pressure: 125 psi

- Air Delivery: 2.0 SCFM @ 90 psi

- Lubrication: Oil-Free (permanently lubricated bearings)

- Gauges: 2 inch diameter (Tank Pressure Gauge, Regulator Pressure Gauge)

- Input Power: 120 V, 60 Hz, AC only, 8.5 Amps

- Net Weight: 33.0 lbs.

- Motor Speed: Approximately 3,450 rpm (no-load speed)

- Electrical Connection: 3-wire grounded plug, 120V, 60Hz, AC only.

- Extension Cord Recommendation: Minimum 14 AWG for 50 feet or less; cords exceeding 100 feet are not recommended.

Usage Features:

- Portability: Equipped with a padded carrying handle, making it easy to transport.

- Tool Bag: Includes a detachable tool bag for convenient storage of accessories, which can also be used on a tool belt.

- Automatic/Off Switch: A simple switch to turn the compressor on (AUTOMATIC position) or off (OFF position). In AUTOMATIC mode, the compressor cycles on and off to maintain tank pressure.

- Pressure Regulator Knob: Allows for precise adjustment of the output air pressure, displayed on the regulator pressure gauge.

- Quick-Connect Air Fitting: Facilitates easy attachment and detachment of air hoses and tools.

- Thermal Overload Switch (Reset Button): Automatically shuts off the compressor if the electric motor's temperature exceeds a predetermined limit, protecting the motor from damage. It can be reset manually after a cooling period.

- Safety Features: Includes a pressure relief valve to prevent over-pressurization and requires the use of eye protection (ANSI Z87.1 compliant) during operation.

- Environmental Considerations: Designed for operation in open, well-ventilated areas, at least 18 inches away from walls or obstructions. Not suitable for use in dusty or contaminated environments, or for supplying breathing quality air.

Maintenance Features:

- Oil-Free Design: The compressor features permanently lubricated bearings, eliminating the need for regular oil changes or lubrication, simplifying maintenance.

- Daily Tank Drainage: Instructions emphasize draining moisture from the air tank daily to prevent corrosion and ensure optimal performance. The drain valve is located at the bottom of the tank for easy access.

- Pressure Relief Valve Check: Users are instructed to check the pressure relief valve before each day of use by pulling the ring to ensure it actuates and seals properly, confirming its functionality as a safety device.

- Air Filter Cleaning: The air filter needs to be removed and cleaned periodically (by blowing compressed air through it) to maintain efficient operation and prevent damage to the pump.

- Tank Inspection: Annual inspection of the air tank for rust, pinholes, or other imperfections is recommended to ensure its safety and integrity.

- General Cleaning: The exterior of the compressor should be kept dry, clean, and free from oil and grease. Cleaning with a clean cloth is recommended, while brake fluids, gasoline, petroleum-based products, or strong solvents should be avoided as they can damage plastic parts.

- Troubleshooting Guide: The manual includes a comprehensive troubleshooting section to help users diagnose and resolve common issues, such as the compressor not running, motor humming, fuses blowing, or air leaks.

- Service Information: Provides contact information for authorized service centers for repairs and parts ordering, emphasizing the use of identical replacement parts to maintain product safety and warranty.

Safety Warnings:

The manual highlights several critical safety warnings, including:

- Read and understand all instructions: Essential to prevent electric shock, fire, or serious personal injury.

- Eye and Hearing Protection: Always wear ANSI Z87.1 compliant eye protection and, if necessary, hearing protection, especially in noisy environments.

- Work Area Safety: Keep the work area clean, well-lit, and free of flammable liquids, gases, or dust. Keep bystanders away.

- Electrical Safety: Avoid body contact with grounded surfaces, do not expose to rain or wet conditions, and inspect cords for damage. Use appropriate outdoor extension cords if operating outside.

- Risk of Fire or Explosion: Do not spray flammable liquids in confined areas. Ensure adequate ventilation and keep the compressor at least 20 feet away from spraying areas and explosive vapors.

- Risk of Bursting: Do not adjust the regulator to exceed the maximum pressure rating of attachments (125 psi).

- Risk of Injury: Never direct the air stream at the body or use compressed air for breathing. Do not carry the compressor while painting.

- Hot Surface: Avoid contact with hot surfaces to prevent injury or damage.

- Disconnect Power: Always disconnect power and air supply, and allow the unit to cool before servicing or making adjustments.

- No Breathing Air: This compressor is not equipped to supply breathing quality air, and additional filtration would be required to meet Grade D breathing specifications.

The Husky H150PL is a robust and user-friendly air compressor, designed with a strong emphasis on safety and durability for a variety of home and light-duty professional applications.