601156_0110 3-5

2. Make sure the steering control levers are in the park

brake position and deck clutch switch is disengaged.

Only start the engine from the operator’s position.

3. Use choke, if unit is equipped with one, when engine is

cold, or if warm engine fails to start within 5 seconds of

cranking. Avoid flooding and operate engine without

choking as soon as possible.

4. Set throttle at approximately 1/2 open position.

5. Insert key in ignition switch and rotate full clockwise to

engage starting motor. Release key when engine starts.

IMPORTANT: The engine starter should not be oper-

ated for periods longer than 30 seconds at a time. An

interval of at least two minutes should be allowed

between such cranking periods to protect the starter from

overheating and burn-out.

6. Perform test to make sure safety start interlock system is

operating properly. Refer to Safety start interlock system

section.

7. As soon as engine begins to run, check to make certain

the oil warning light, engine light and alternator warning

light (if applicable) are off. If not, stop engine

immediately and check for the cause.

8. Allow the engine to idle a few minutes before advancing

the throttle and/or engaging the deck clutch.

9. Before stopping the engine, place the steering control

levers in the park brake position, disengage the deck

clutch, and throttle back to low idle for a couple of

minutes; then rotate ignition key counter-clockwise to the

OFF position. Remove the key from switch before

leaving the tractor.

Stopping the engine

Use the following procedure to shut off the engine after

operating the equipment.

1. Place the steering control levers in the park brake

position

2. Disengage the deck clutch

3. Throttle back to low idle for a couple of minutes

4. Rotate ignition key counter-clockwise to the OFF

position. Remove the key from switch before leaving the

tractor.

Moving tractor with stalled engine

If it becomes necessary to move the tractor when the engine is

inoperative, the transaxles are equipped with bypass valves.

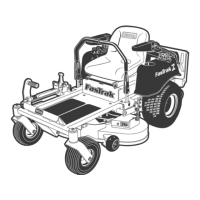

FasTrak 36/42 (Mini FasTrak 36/42) - Before moving the

unit, pull out on the bypass valve rods and slide them into the

slot to lock in position. Both bypass valve rods are located

underneath the rear of the tractor at the back of the transaxle.

(Fig. 3-5)

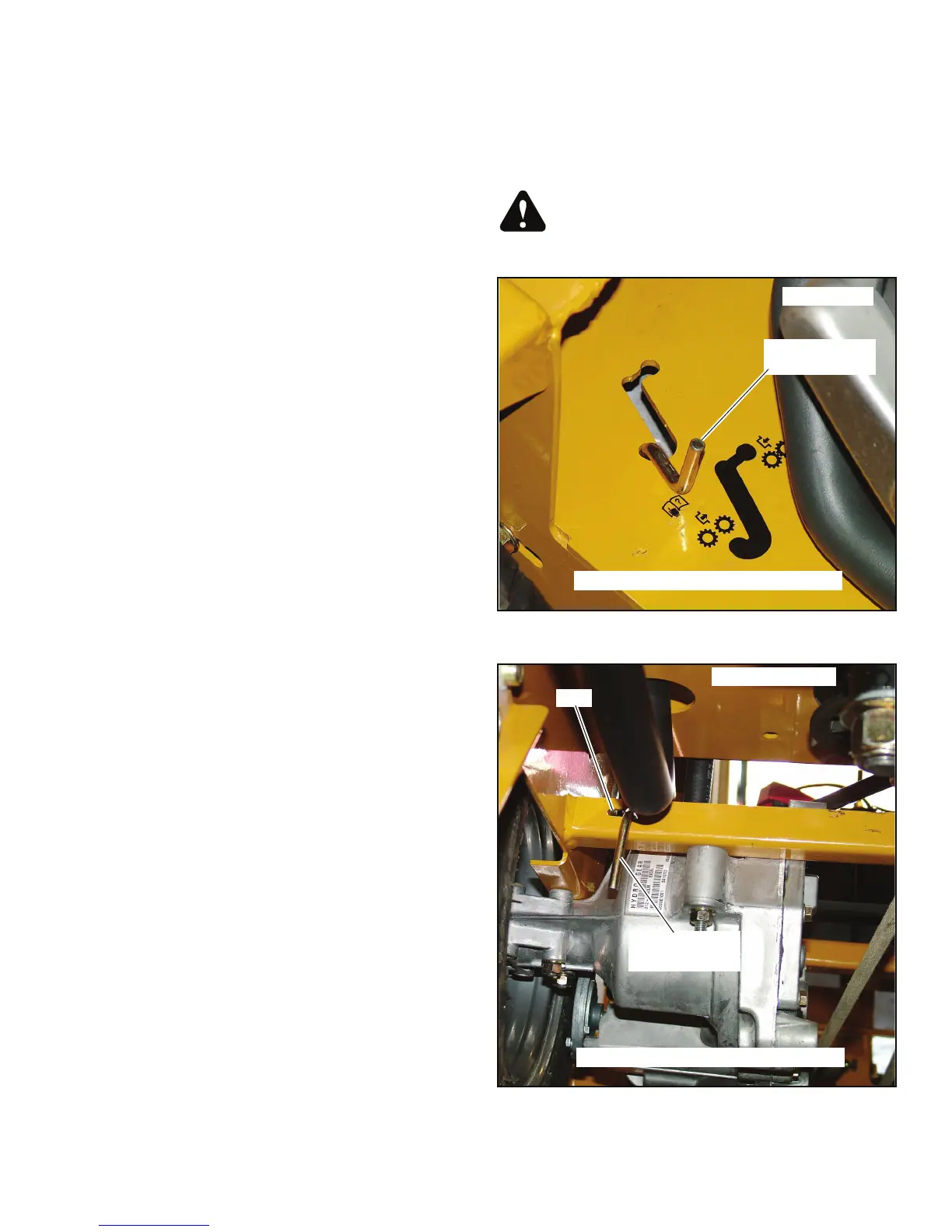

FasTrak 48/54 - Before moving the unit, pull up on the

bypass valve rod and slide it in the slot to the disengaged

position. (Fig. 3-6)

The steering control levers must be placed in the neutral

position, to release the park brakes, so that the tractor can be

moved. Both bypass valve rods are located at the front corners

of the engine on the engine platform.

Do not tow the machine. Move it by hand or use a winch to

load on a trailer for transporting.

When transporting on another vehicle, the tractor must be

secured.

IMPORTANT: Always make certain the two bypass valves

are returned to their operating position before running the trac-

tor following repairs.

WARNING: Allow engine exhaust manifold to cool

before engaging or disengaging the bypass valves. The

bypass valve rods are located close to the exhaust sys-

tem.

Fig. 3-5

Fig. 3-6

Bypass valve rod shown in towing position

Bypass valve rod

(Left rod shown)

FasTrak 48/54

Mini FasTrak 36/42

Bypass valve rod

(Left rod shown)

(Viewed from the rear left underneath side)

Slot

Loading...

Loading...