Pre

aration For

For OVERSEAS CUSTOMERS: If you use

the Metric System, See the American-to-

Metric conversion table in the rear of this

manual. Most illustrations in this manual will

provide both American and Metric

dimensions.

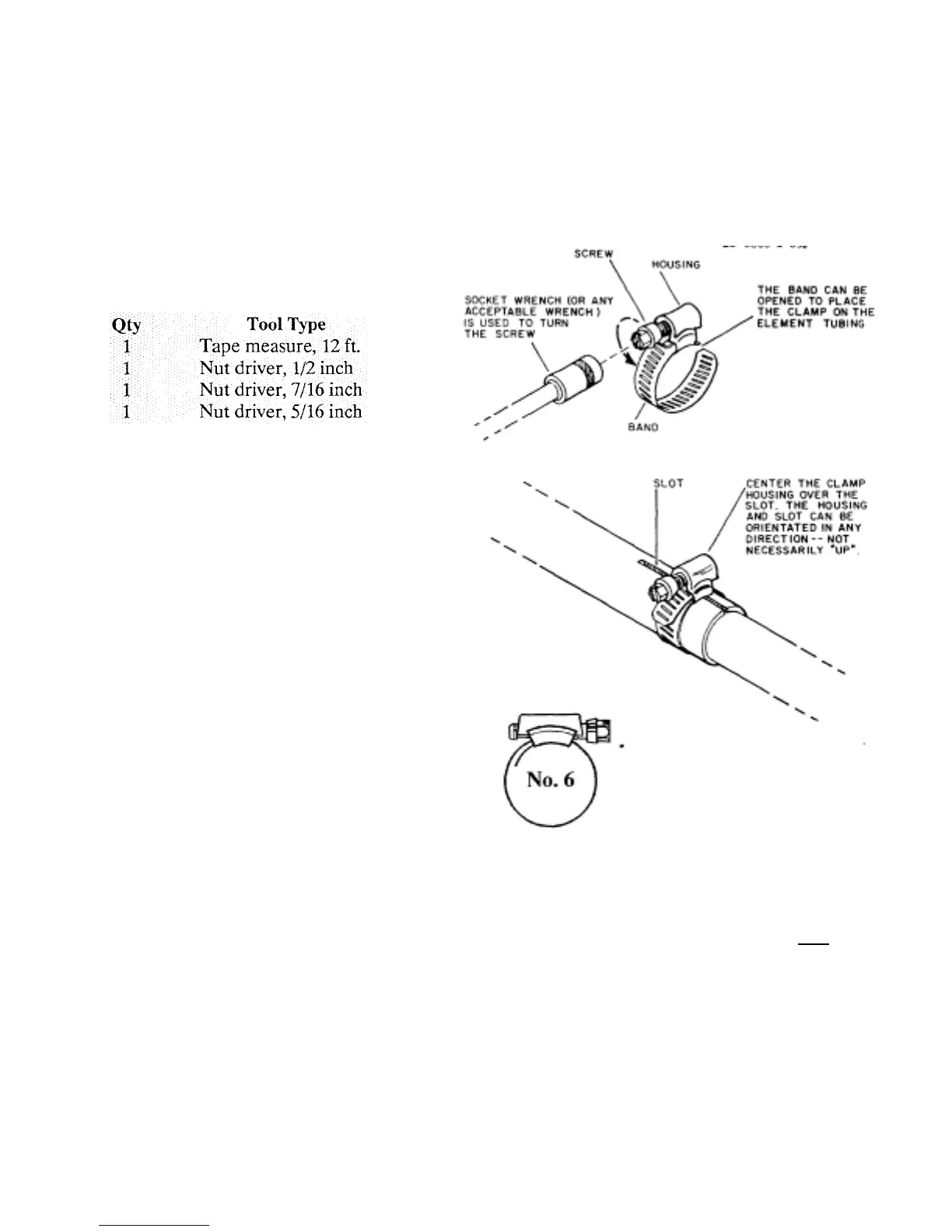

After adjustment of the tubing lengths,

tighten the clamp with a 5/16 inch nut driver,

socket, or open end wrench until the tubing

will not twist or telesco

e.

Do not overti

hten the tubin

clam

s.

Tools: The following tools are required for

eas

assembl

of the 64DX beam:

Standard wrenches or adjustable wrenches

ma

also be used in

lace of the nut drivers.

When unpacking your antenna, check inside

of all tubing for small parts and elements. To

conserve space, these smaller articles are

sometimes put inside larger pieces. Check all

parts against the parts list in the rear of this

manual to ensure no

arts are missin

.

Feedline and SWR

Model 64DX can be matched to 50 ohm coax

using the balun supplied. Without the balun,

the input impedance is 200 ohms. The SWR

can be 1.1:1 with proper installation and

necessar

care taken in assembl

.

NOTE: If resonance is affected by

environmental surroundings, shorten the

Driven Element to raise the frequency and

lengthen the Driven Element to lower the

frequency. Shorten the Driven Element in 1/4

inch increments until desired results are

obtained.

Installation of Tubin

Clam

s

Select the proper size tubing clamp as shown

in the chart in Figure l. When installing the

clamp, place the clamp near the tube end with

the top of the clamp over the slot in the tube

as shown.

Part Descri

tion Fits

No. Tubing

Sizes

358756 Clamp, Size #6 1/2

all stainless steel and 3/4"

5/16" hex head screw

Figure 1 Tubing clamp

Assembly

Loading...

Loading...