Description 4000 SRM 481

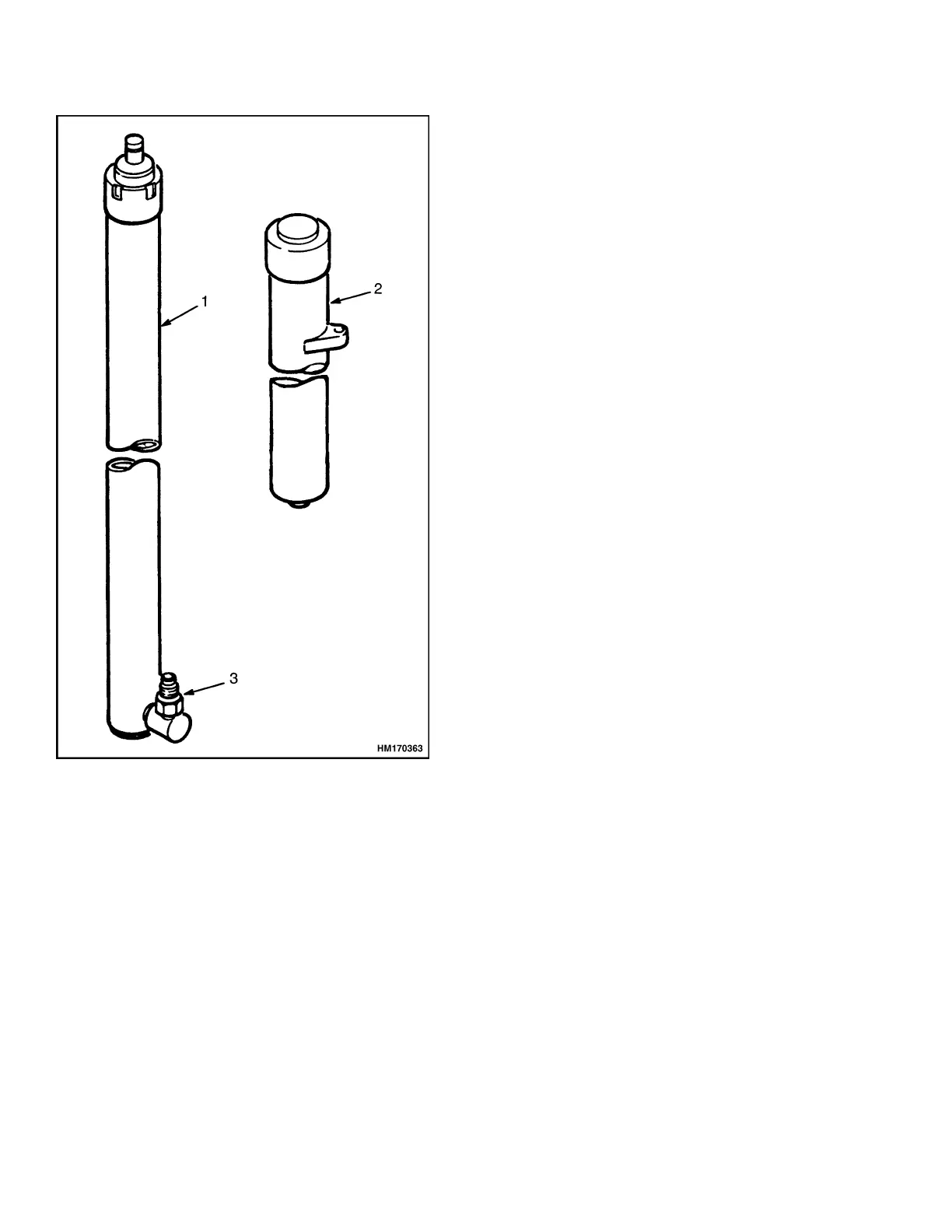

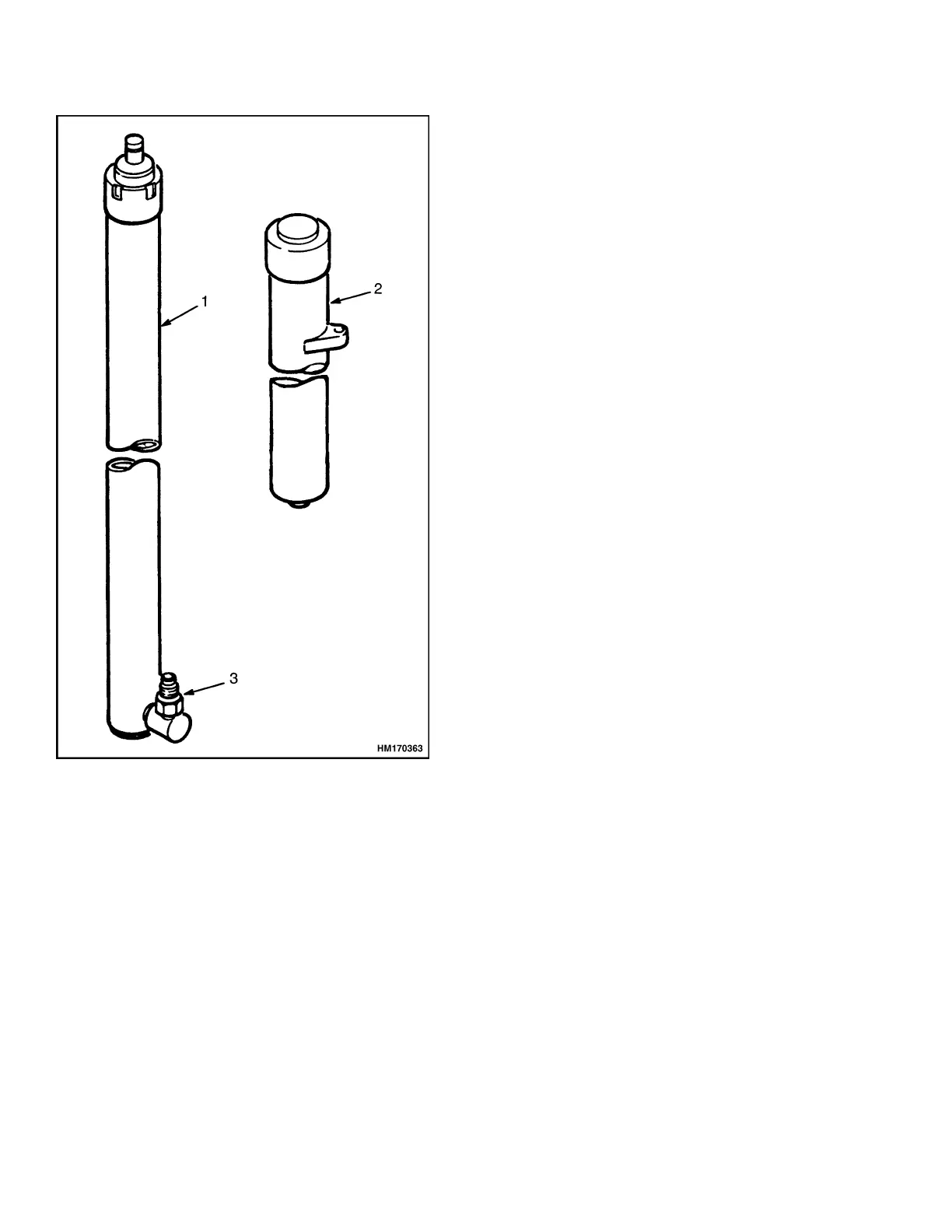

1. MAIN CYLINDER

2. FREE-LIFT CYLINDER

3. LOWERING CONTROL VALVE

Figure 1. Lift Cylinders

Spacers are used in some cylinders to limit the stroke

of the piston rod. Worn spacers must be replaced

with the same-size spacer.

During operation, some hydraulic oil will leak past

the piston area to the rod end of the lift cylinder.

Small leaks are permitted if the internal leak rate

of the hydraulic system is not greater than the spec-

ification. An internal check valve is installed in the

piston of the main-lift cylinders. When the piston rod

extends, the pressure increases more quickly on any

oil in the rod end of the lift cylinder. The hydraulic oil

transfers through the check valve to the piston end of

the free-lift cylinder. This action prevents hydraulic

damage to the single lip seal and the wiper ring. See

Figure 3.

Lift cylinders and other hydraulic parts can have

some internal leaks. Internal leakage will increase

as the temperature of the hydraulic oil increases.

The internal leak rate of the hydraulic system is

checked periodically. See the sections Periodic

Maintenance 8000 SRM 1197, Periodic Main-

tenance 8000 SRM 970, Periodic Maintenance

8000 SRM 1379, or Periodic Maintenance 8000

SRM 1027, Maintenance Schedule for your lift

truck and Mast, Repair 4000 SRM 482 for test

procedures and leakage rate specifications.

LOWERING CONTROL VALVE

A lowering control valve (also called a velocity fuse)

is installed in the inlet port of each lift cylinder. See

Figure 2. It permits easy entry of hydraulic oil into

the cylinder, but gives a restriction when the rod is

retracted. This restriction limits the speed that a

load on the forks can be lowered.

There are two types of lowering control valves: low-

pressure designs and high-pressure designs. Both

types have the same function and similar operation.

Themostcommontypeofvalvehasadesignthat

has good operation using large flows and lower pres-

sures. Some lift trucks have a lift system design us-

ing higher pressures and a lower flow. These systems

need a different type of lowering control valve.

The most common type of lowering control valve (low

pressure) uses these parts: (1) a special fitting for

the valve body, (2) a spring, and (3) a special washer.

There is a variation in the shapes of the special

washer. Different lift cylinders use different shapes

of special washers. The volume of the hydraulic oil

flowing through the inlet port controls the shape

of the special washer. A typical shape of a special

washerisshowninFigure2. Whenthepistonrod

is lowered, the oil flow pushes against the special

washer and spring. When the oil flow reaches the

limit, the special washer is moved against the spe-

cial fitting. The oil then flows only through the hole

in the center of the special washer. This restriction

permits the piston rod to lower only at a maximum

controlled speed.

2

Loading...

Loading...